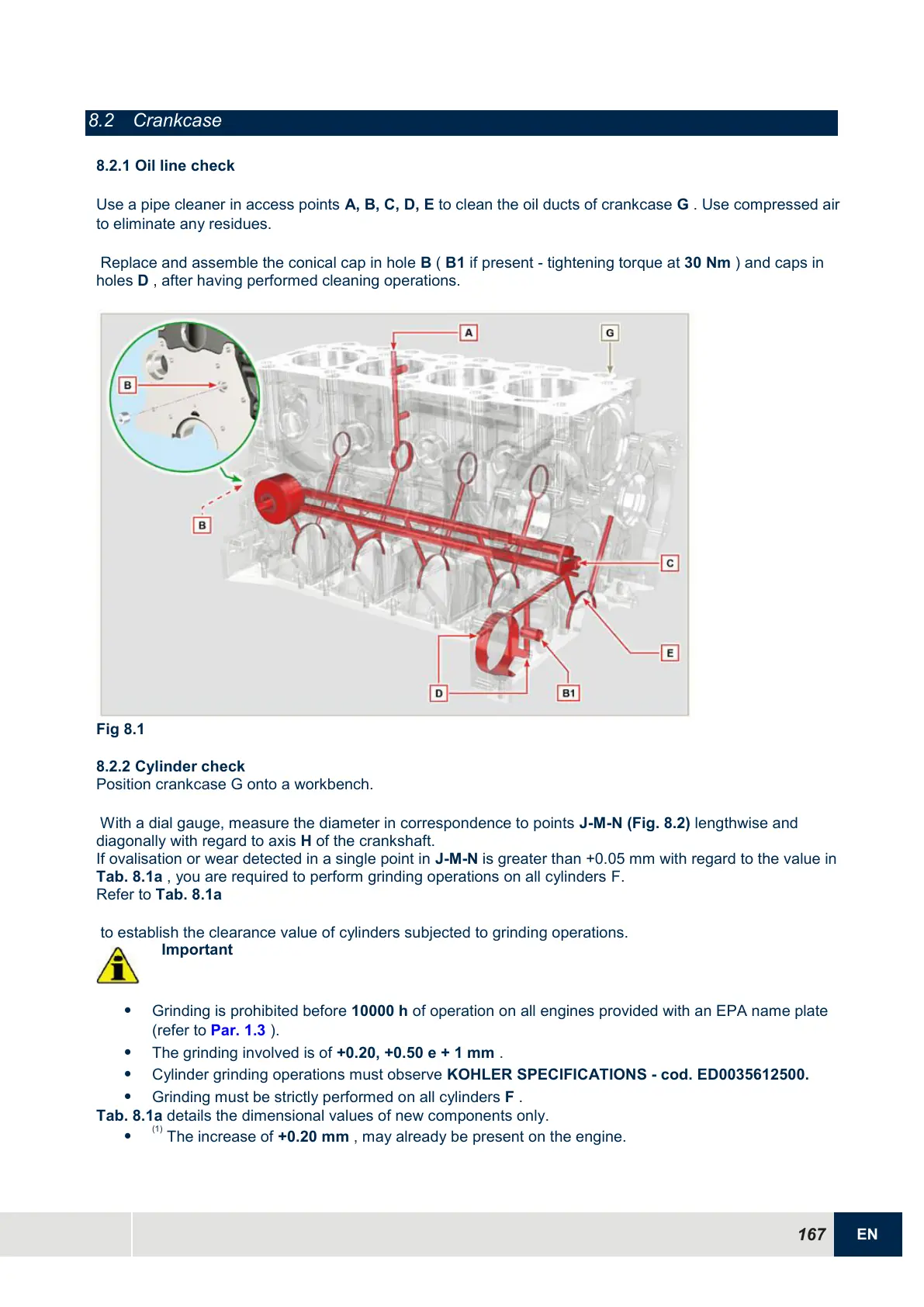

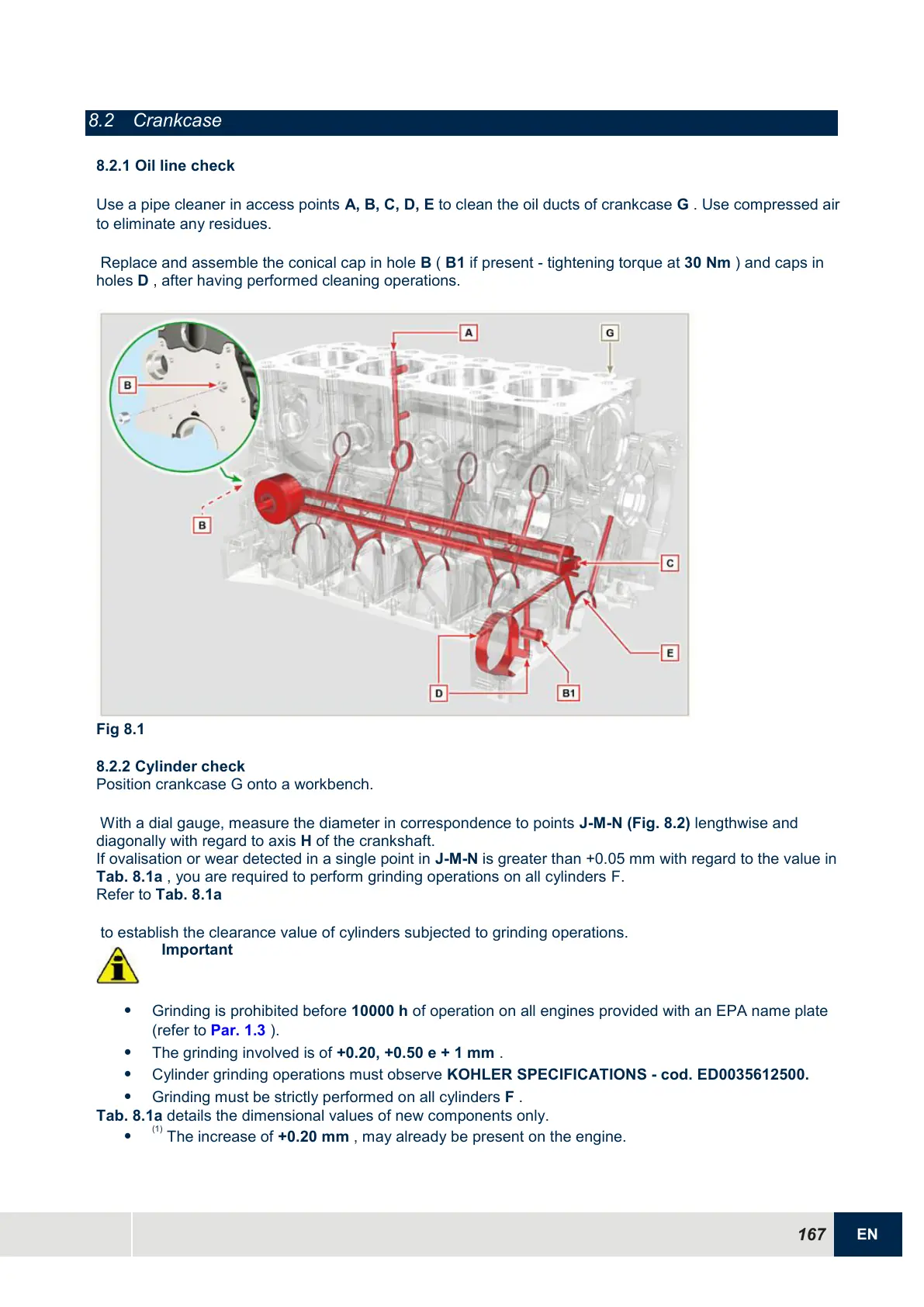

8.2.1 Oil line check

Use a pipe cleaner in access points

A, B, C, D, E

to clean the oil ducts of crankcase

G

. Use compressed air

to eliminate any residues.

Replace and assemble the conical cap in hole B ( B1 if present - tightening torque at 30 Nm ) and caps in

holes D , after having performed cleaning operations.

Fig 8.1

8.2.2 Cylinder check

Position crankcase G onto a workbench.

With a dial gauge, measure the diameter in correspondence to points J-M-N (Fig. 8.2) lengthwise and

diagonally with regard to axis H of the crankshaft.

If ovalisation or wear detected in a single point in J-M-N is greater than +0.05 mm with regard to the value in

Tab. 8.1a , you are required to perform grinding operations on all cylinders F.

Refer to Tab. 8.1a

to establish the clearance value of cylinders subjected to grinding operations.

Important

Grinding is prohibited before 10000 h of operation on all engines provided with an EPA name plate

(refer to Par. 1.3 ).

The grinding involved is of +0.20, +0.50 e + 1 mm .

Cylinder grinding operations must observe KOHLER SPECIFICATIONS - cod. ED0035612500.

Grinding must be strictly performed on all cylinders F .

Tab. 8.1a details the dimensional values of new components only.

(1)

The increase of +0.20 mm , may already be present on the engine.

Loading...

Loading...