9.4 Oil sump unit assembly

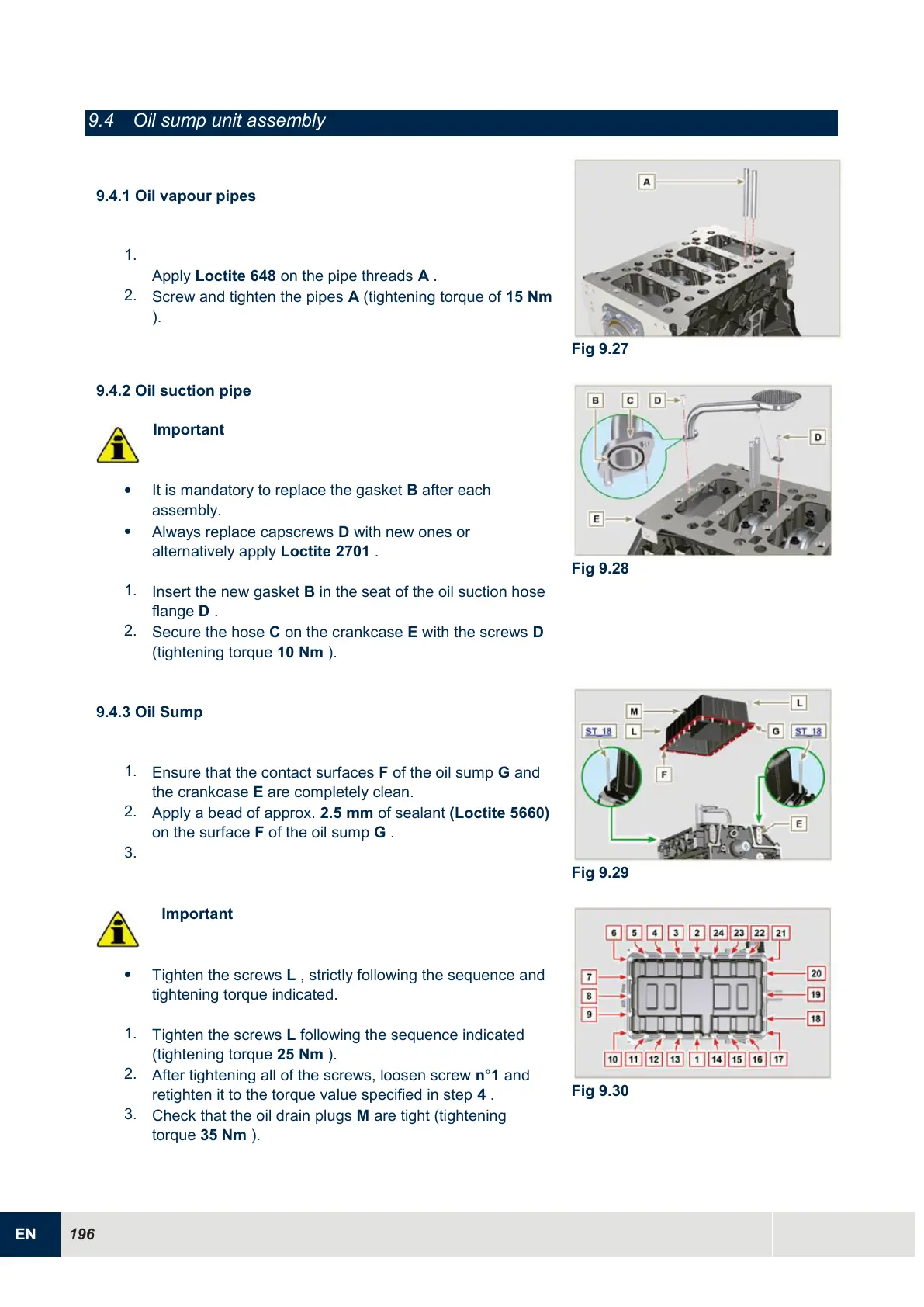

9.4.1 Oil vapour pipes

1.

Apply Loctite 648 on the pipe threads A .

2.

Screw and tighten the pipes A (tightening torque of 15 Nm

).

9.4.2 Oil suction pipe

Important

It is mandatory to replace the gasket B after each

assembly.

Always replace capscrews D with new ones or

alternatively apply Loctite 2701 .

1.

Insert the new gasket B in the seat of the oil suction hose

flange D .

2.

Secure the hose C on the crankcase E with the screws D

(tightening torque 10 Nm ).

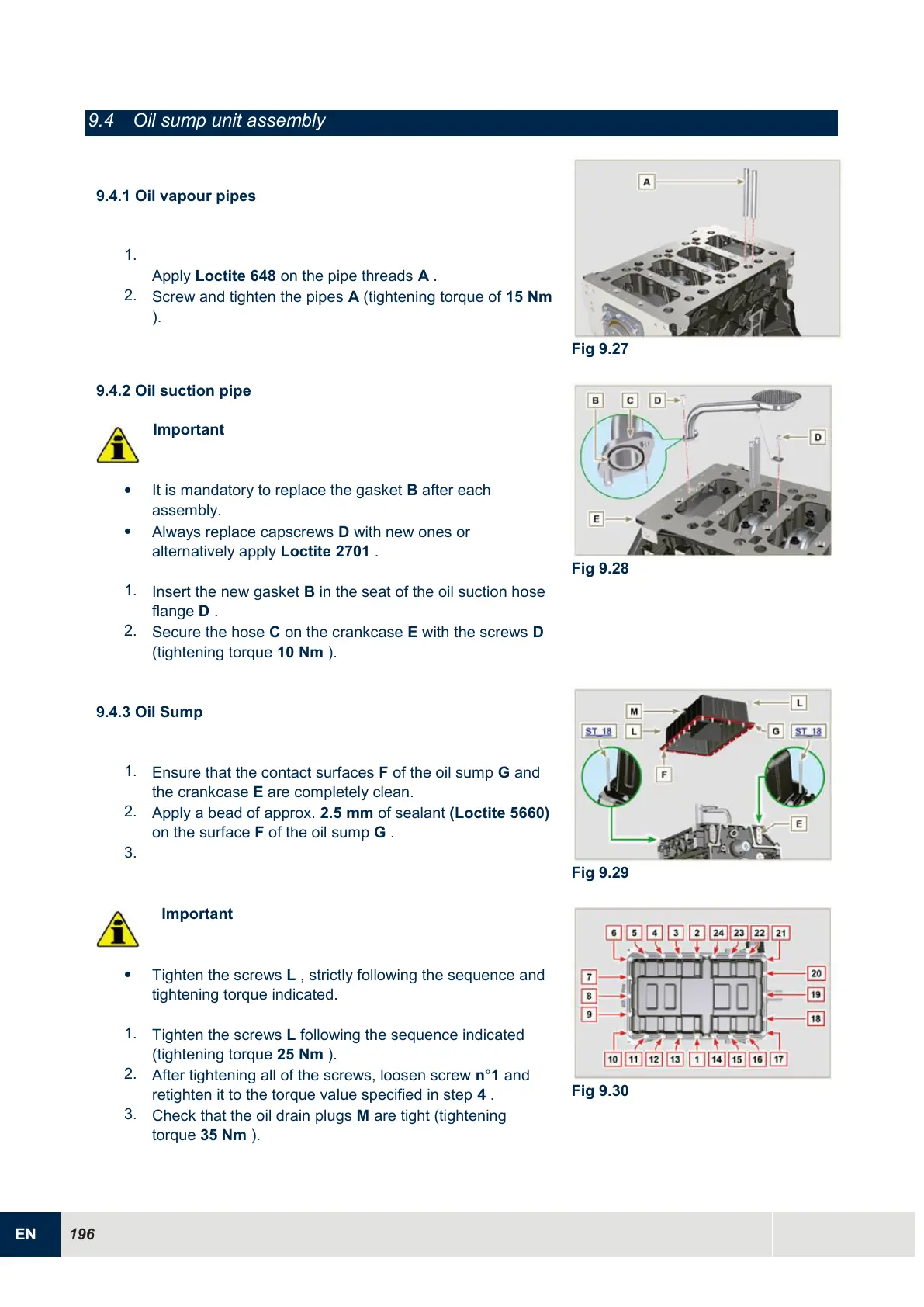

9.4.3 Oil Sump

1.

Ensure that the contact surfaces F of the oil sump G and

the crankcase E are completely clean.

2.

Apply a bead of approx. 2.5 mm of sealant (Loctite 5660)

on the surface F of the oil sump G .

3.

Important

Tighten the screws L , strictly following the sequence and

tightening torque indicated.

1.

Tighten the screws L following the sequence indicated

(tightening torque 25 Nm ).

2.

After tightening all of the screws, loosen screw n°1 and

retighten it to the torque value specified in step 4 .

3.

Check that the oil drain plugs M are tight (tightening

torque 35 Nm ).

Loading...

Loading...