9.2 Assembly recommendations

The information is laid out in sequence, the intervention methods have been selected, tested and

approved by the manufacturer's technicians.

This chapter describes the installation procedures for the assemblies and/ or individual components

which have already been checked, overhauled or possibly replaced with original spare parts.

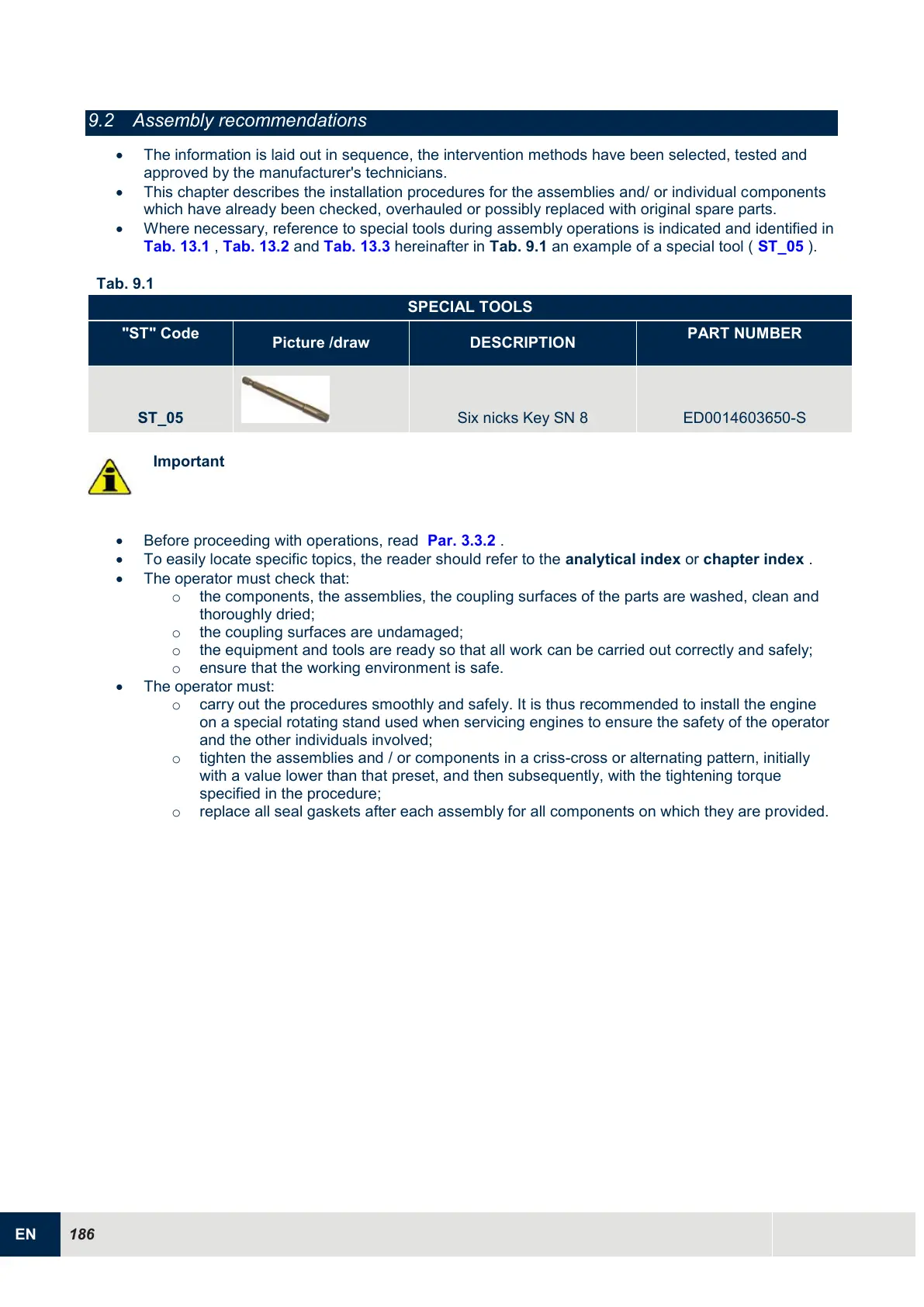

Where necessary, reference to special tools during assembly operations is indicated and identified in

Tab. 13.1 , Tab. 13.2 and Tab. 13.3 hereinafter in Tab. 9.1 an example of a special tool ( ST_05 ).

Tab. 9.1

Important

Before proceeding with operations, read Par. 3.3.2 .

To easily locate specific topics, the reader should refer to the analytical index or chapter index .

The operator must check that:

o the components, the assemblies, the coupling surfaces of the parts are washed, clean and

thoroughly dried;

o the coupling surfaces are undamaged;

o the equipment and tools are ready so that all work can be carried out correctly and safely;

o ensure that the working environment is safe.

The operator must:

o carry out the procedures smoothly and safely. It is thus recommended to install the engine

on a special rotating stand used when servicing engines to ensure the safety of the operator

and the other individuals involved;

o tighten the assemblies and / or components in a criss-cross or alternating pattern, initially

with a value lower than that preset, and then subsequently, with the tightening torque

specified in the procedure;

o replace all seal gaskets after each assembly for all components on which they are provided.

Loading...

Loading...