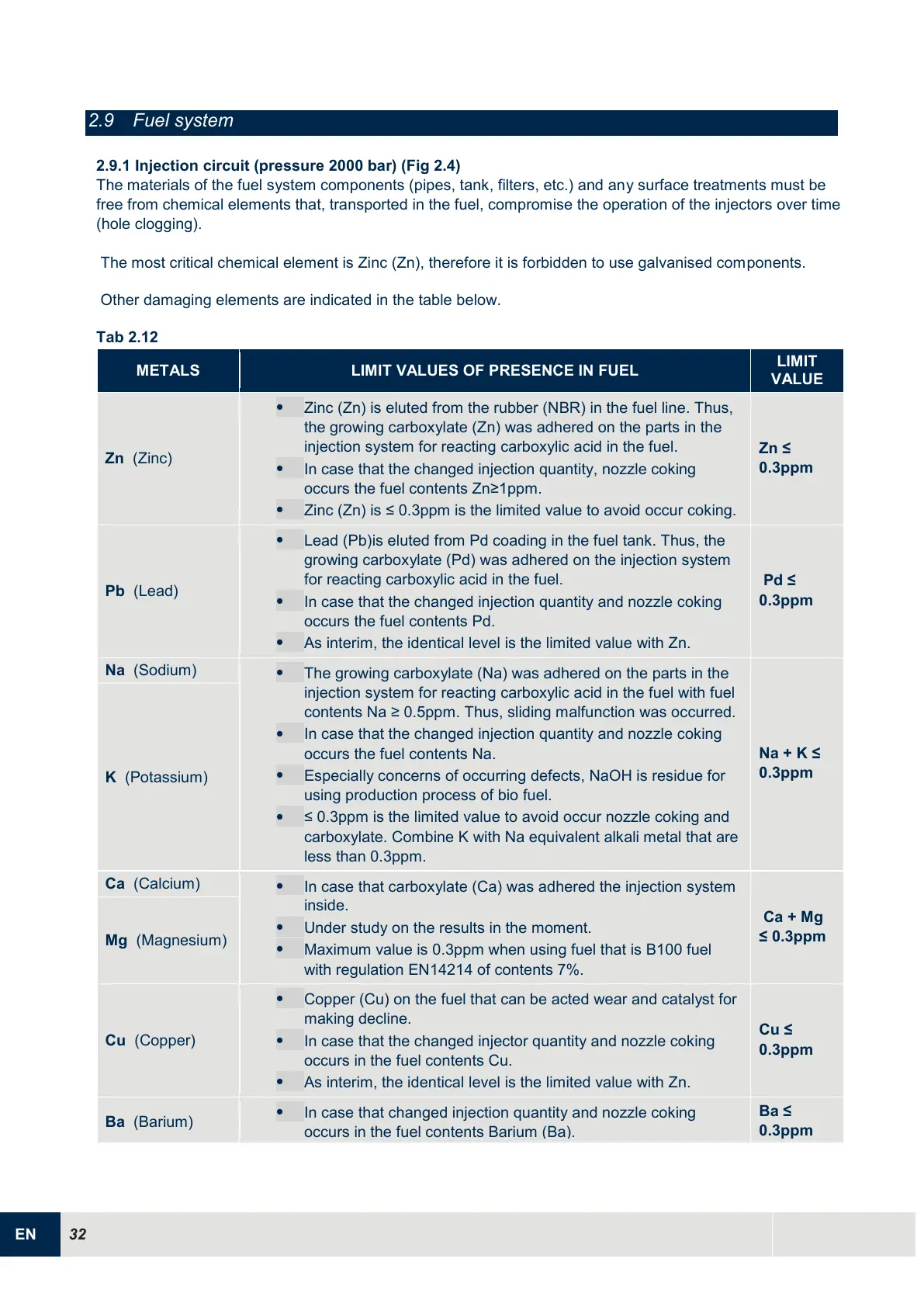

2.9 Fuel system

2.9.1 Injection circuit (pressure 2000 bar) (Fig 2.4)

The materials of the fuel system components (pipes, tank, filters, etc.) and any surface treatments must be

free from chemical elements that, transported in the fuel, compromise the operation of the injectors over time

(hole clogging).

The most critical chemical element is Zinc (Zn), therefore it is forbidden to use galvanised components.

Other damaging elements are indicated in the table below.

Tab 2.12

LIMIT VALUES OF PRESENCE IN FUEL

Zinc (Zn) is eluted from the rubber (NBR) in the fuel line. Thus,

the growing carboxylate (Zn) was adhered on the parts in the

injection system for reacting carboxylic acid in the fuel.

In case that the changed injection quantity, nozzle coking

occurs the fuel contents Zn≥1ppm.

Zinc (Zn) is ≤ 0.3ppm is the limited value to avoid occur coking.

Lead (Pb)is eluted from Pd coading in the fuel tank. Thus, the

growing carboxylate (Pd) was adhered on the injection system

for reacting carboxylic acid in the fuel.

In case that the changed injection quantity and nozzle coking

occurs the fuel contents Pd.

As interim, the identical level is the limited value with Zn.

The growing carboxylate (Na) was adhered on the parts in the

injection system for reacting carboxylic acid in the fuel with fuel

contents Na ≥ 0.5ppm. Thus, sliding malfunction was occurred.

In case that the changed injection quantity and nozzle coking

occurs the fuel contents Na.

Especially concerns of occurring defects, NaOH is residue for

using production process of bio fuel.

≤ 0.3ppm is the limited value to avoid occur nozzle coking and

carboxylate. Combine K with Na equivalent alkali metal that are

less than 0.3ppm.

In case that carboxylate (Ca) was adhered the injection system

inside.

Under study on the results in the moment.

Maximum value is 0.3ppm when using fuel that is B100 fuel

with regulation EN14214 of contents 7%.

Copper (Cu) on the fuel that can be acted wear and catalyst for

making decline.

In case that the changed injector quantity and nozzle coking

occurs in the fuel contents Cu.

As interim, the identical level is the limited value with Zn.

In case that changed injection quantity and nozzle coking

occurs in the fuel contents Barium (Ba).

Loading...

Loading...