As interim, the identical level is the limited value with Zn.

Phosphorus (P) in the fuel can poison catalyst.

No failure case is in the injection system in the moment.

Maximum value is 0.3ppm when using a B100 fuel with

regulation EN 14214 of contents 7%.

These metals are regulated in EN14214

Important

The high pressure supply injection system is highly susceptible to damage if the fuel is

contaminated.

It is crucial that all components of the injection circuit are thoroughly cleaned before the components

are removed.

Thoroughly wash and clean the engine before maintenance.

Contamination in the injection system may cause a reduction in in performance or engine faults.

If the engine is cleaned with high pressure washer, then the nozzle must be kept at a minimum

distance of 200mm from the surface, and not directed at electrical components and connectors.

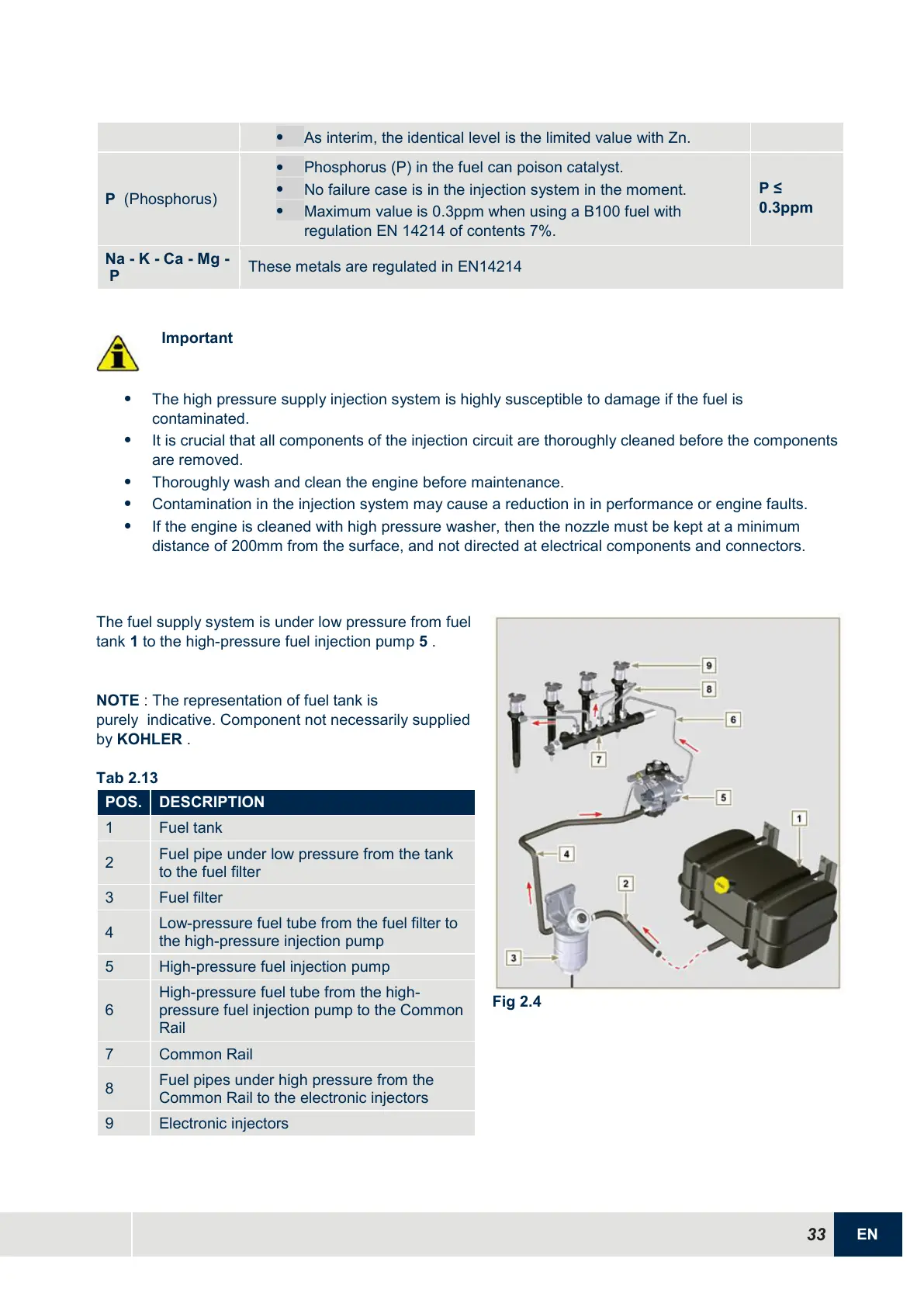

The fuel supply system is under low pressure from fuel

tank

1

to the high-pressure fuel injection pump

5

.

NOTE

: The representation of fuel tank is

purely indicative. Component not necessarily supplied

by

KOHLER

.

Tab 2.13

Fuel pipe under low pressure from the tank

to the fuel filter

Low-pressure fuel tube from the fuel filter to

the high-pressure injection pump

High-pressure fuel injection pump

High-pressure fuel tube from the high-

pressure fuel injection pump to the Common

Rail

Fuel pipes under high pressure from the

Common Rail to the electronic injectors

Loading...

Loading...