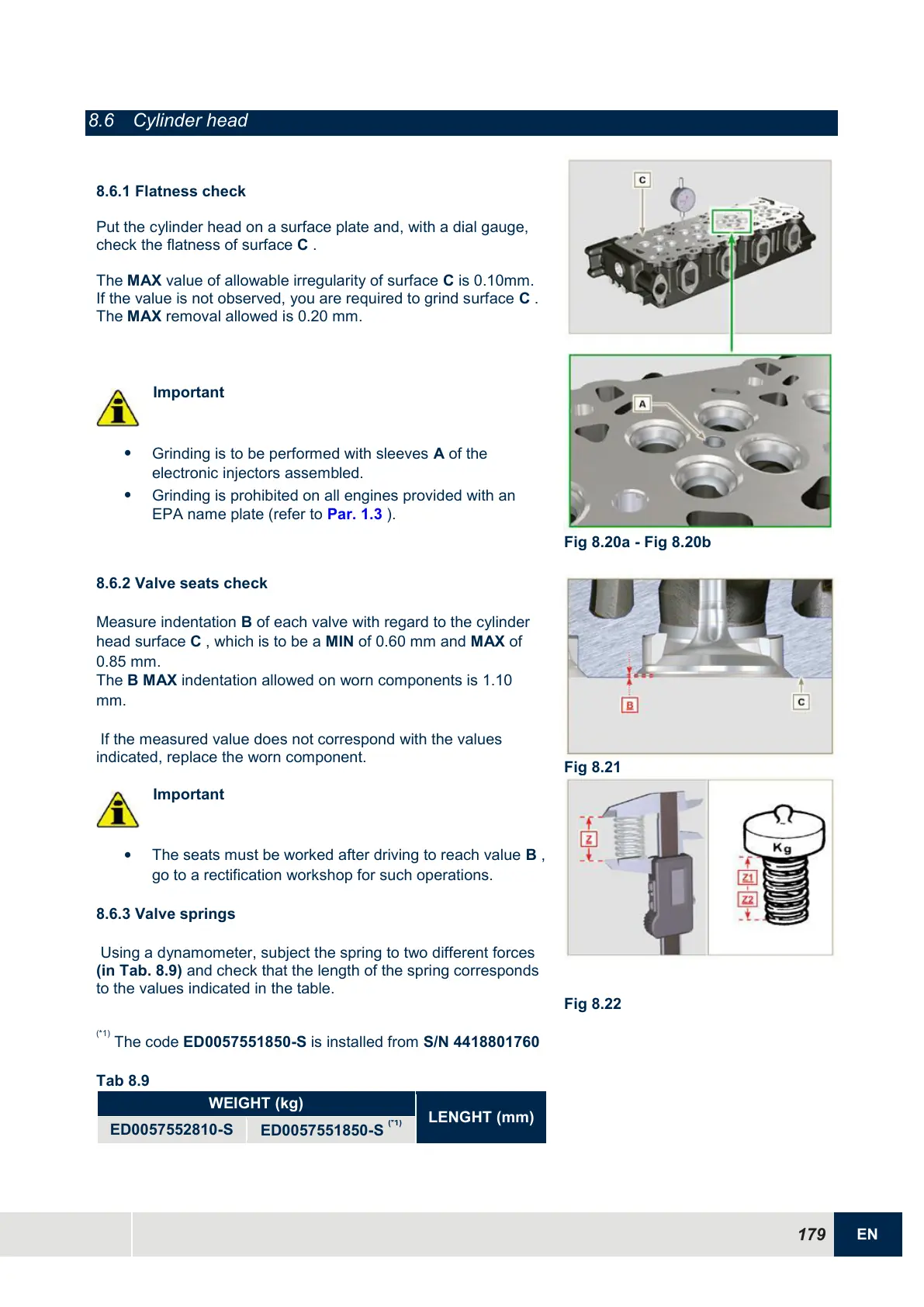

8.6.1 Flatness check

Put the cylinder head on a surface plate and, with a dial gauge,

check the flatness of surface C .

The MAX value of allowable irregularity of surface C is 0.10mm.

If the value is not observed, you are required to grind surface C .

The MAX removal allowed is 0.20 mm.

Important

Grinding is to be performed with sleeves A of the

electronic injectors assembled.

Grinding is prohibited on all engines provided with an

EPA name plate (refer to Par. 1.3 ).

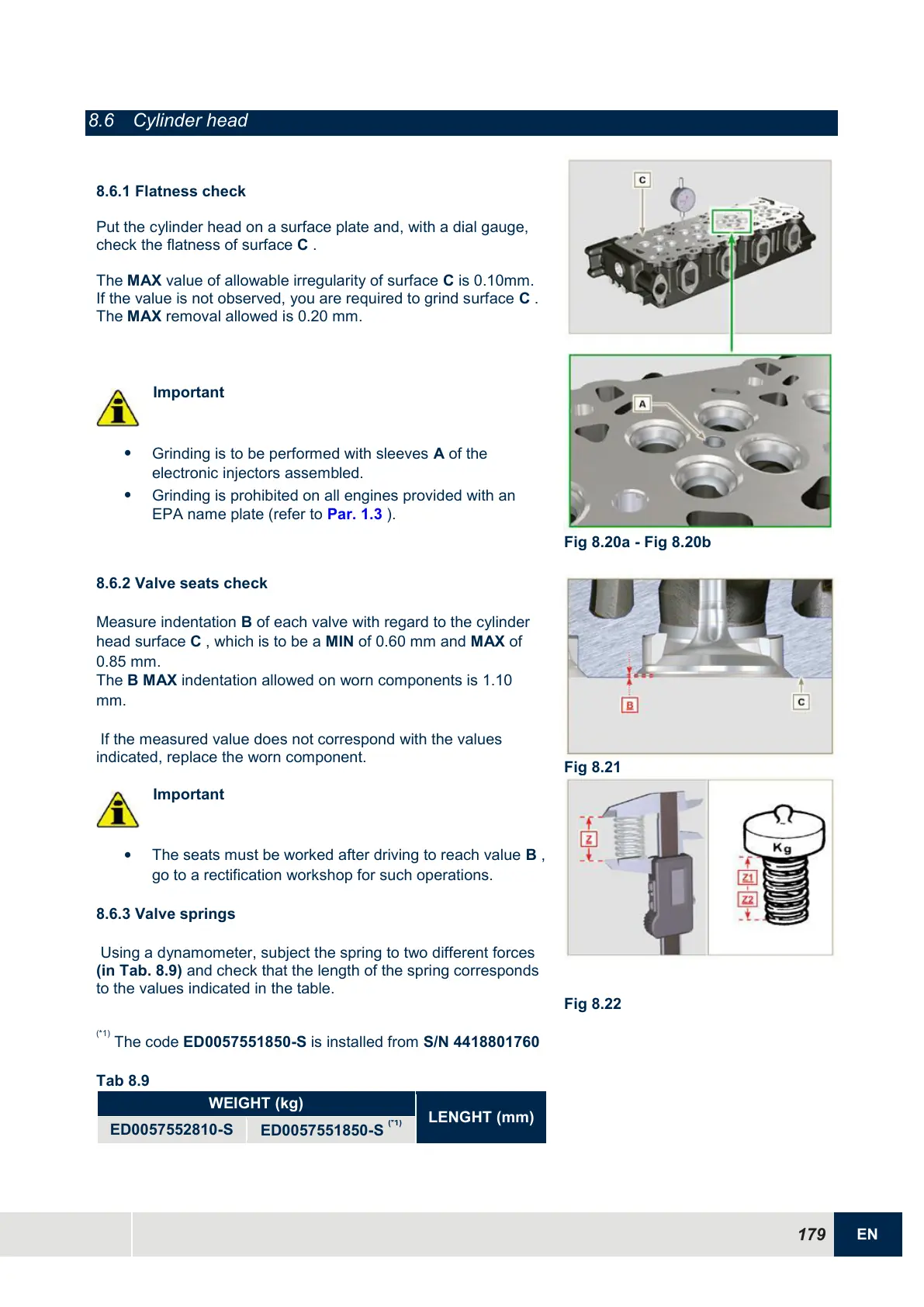

8.6.2 Valve seats check

Measure indentation

B

of each valve with regard to the cylinder

head surface

C

, which is to be a

MIN

of 0.60 mm and

MAX

of

0.85 mm.

The

B MAX

indentation allowed on worn components is 1.10

mm.

If the measured value does not correspond with the values

indicated, replace the worn component.

Important

The seats must be worked after driving to reach value B ,

go to a rectification workshop for such operations.

8.6.3 Valve springs

Using a dynamometer, subject the spring to two different forces

(in Tab. 8.9) and check that the length of the spring corresponds

to the values indicated in the table.

(*1)

The code

ED0057551850-S

is installed from

S/N 4418801760

Tab 8.9

Loading...

Loading...