250hrs. However, the engine oil must be changed when the Total Base Number TBN is reduced to

6.0 mgKOH/g test method ASTM D4739. Do not use low SAPS engine oils.

KDI Electronic Injection uncertified Engines (no EGR engines)

Those engines are designed for fuels in accordance with EN 590 and ASTM D975 for a cetane

number of at least 45. Since those engines are not equipped with exhaust gas after-treatment, they

can be operated with diesel fuels with sulfur content up to 2000 mg/kg (ppm). Fuels with a sulfur

content > 15 mg/kg demand a shorter lubricating oil change interval. This is set at 250hrs. However,

the engine oil must be changed when the Total Base Number TBN is reduced to 6.0 mgKOH/g test

method ASTM D4739.

2.5.1 Fuel for low temperatures

When operating the engine in ambient temperatures lower than 0 degrees C, use suitable low

temperature fuel normally available from fuel distributors and corresponding to the specifications of

Tab. 2.3 .

These fuels reduce the formation of paraffin in diesel at low temperatures.

When paraffin forms in the diesel, the fuel filter becomes blocked interrupting the flow of fuel.

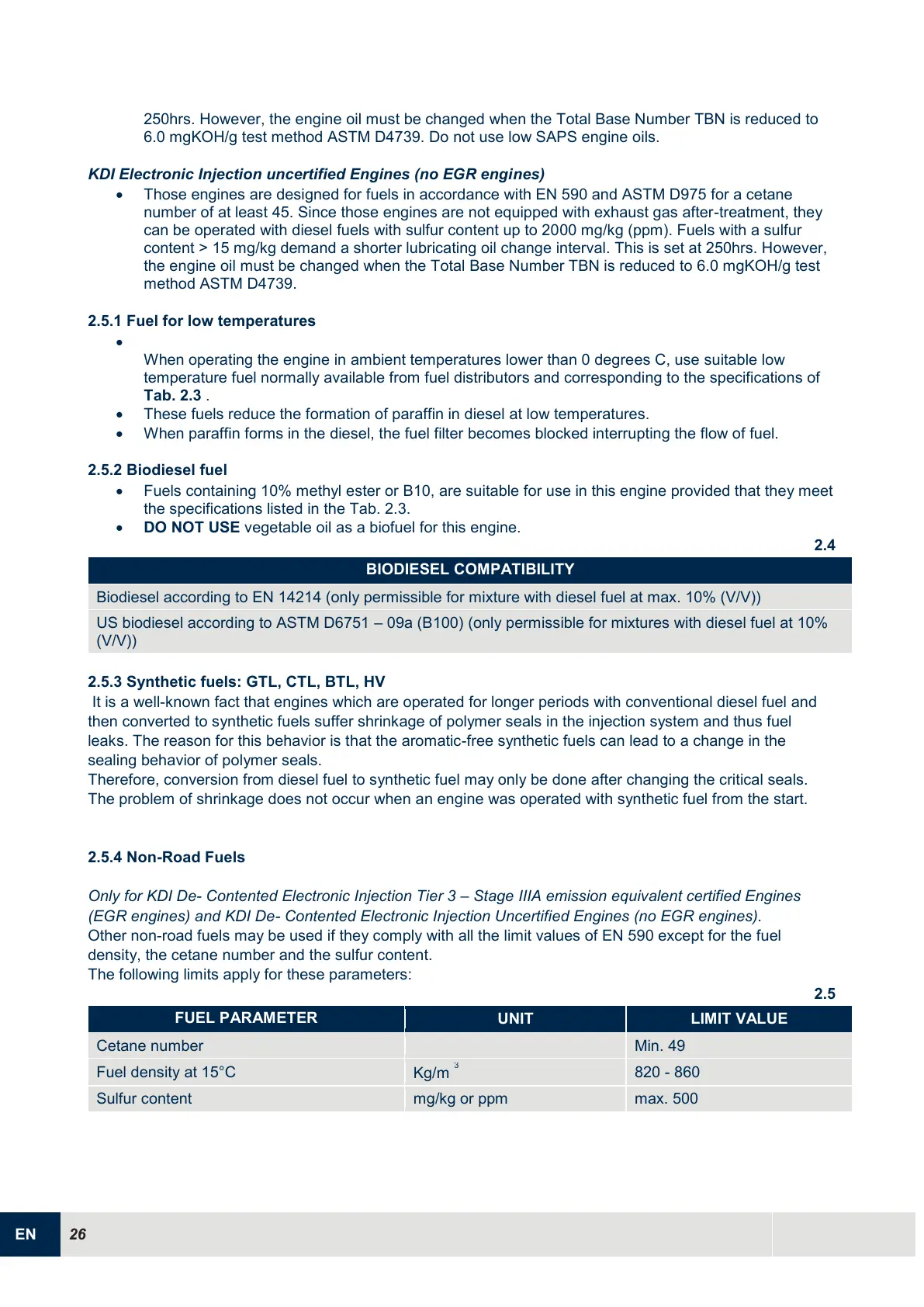

2.5.2 Biodiesel fuel

Fuels containing 10% methyl ester or B10, are suitable for use in this engine provided that they meet

the specifications listed in the Tab. 2.3.

DO NOT USE vegetable oil as a biofuel for this engine.

2.4

Biodiesel according to EN 14214 (only permissible for mixture with diesel fuel at max. 10% (V/V))

US biodiesel according to ASTM D6751 – 09a (B100) (only permissible for mixtures with diesel fuel at 10%

(V/V))

2.5.3 Synthetic fuels: GTL, CTL, BTL, HV

It is a well-known fact that engines which are operated for longer periods with conventional diesel fuel and

then converted to synthetic fuels suffer shrinkage of polymer seals in the injection system and thus fuel

leaks. The reason for this behavior is that the aromatic-free synthetic fuels can lead to a change in the

sealing behavior of polymer seals.

Therefore, conversion from diesel fuel to synthetic fuel may only be done after changing the critical seals.

The problem of shrinkage does not occur when an engine was operated with synthetic fuel from the start.

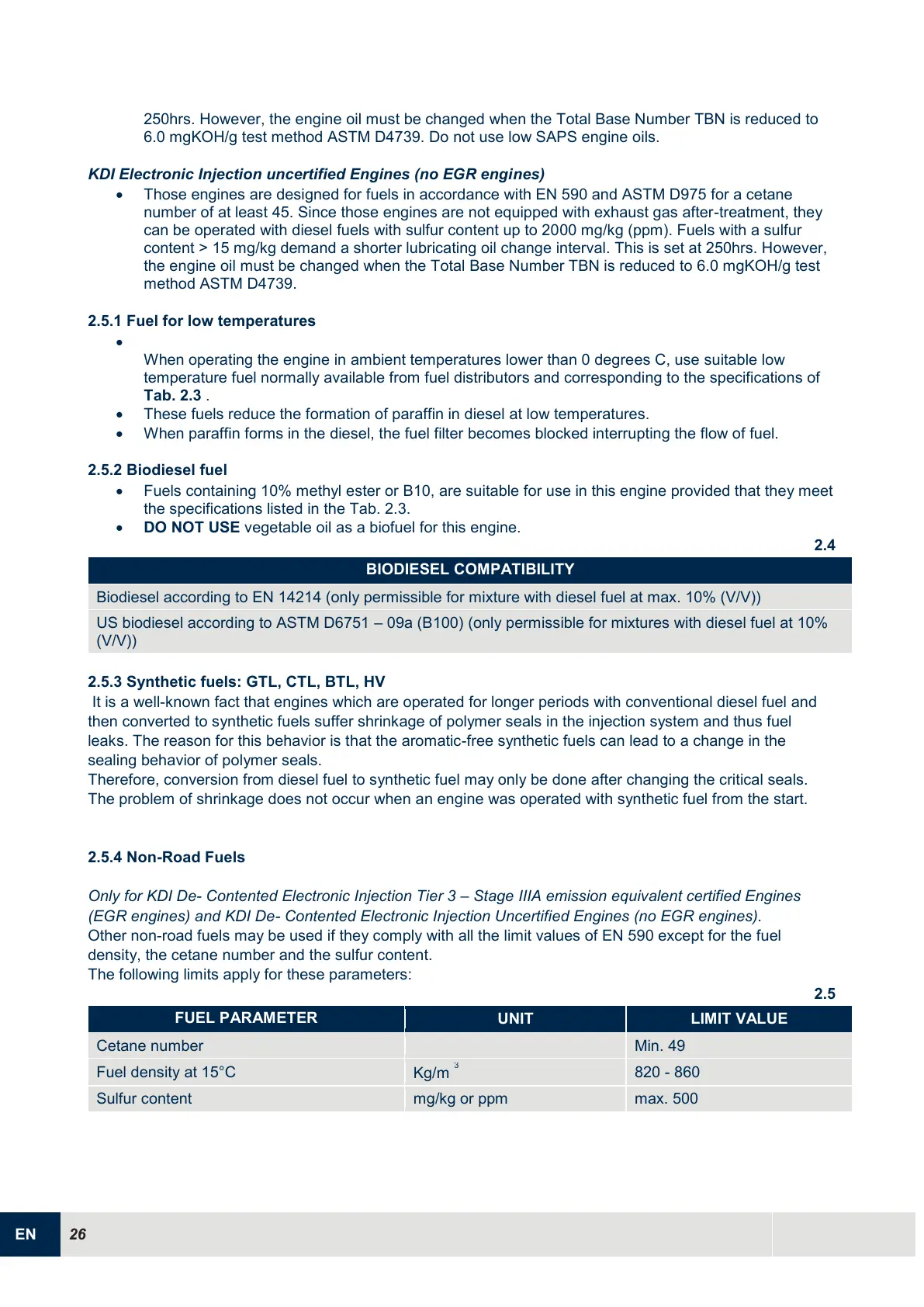

2.5.4 Non-Road Fuels

Only for KDI De- Contented Electronic Injection Tier 3 – Stage IIIA emission equivalent certified Engines

(EGR engines) and KDI De- Contented Electronic Injection Uncertified Engines (no EGR engines).

Other non-road fuels may be used if they comply with all the limit values of EN 590 except for the fuel

density, the cetane number and the sulfur content.

The following limits apply for these parameters:

2.5

Loading...

Loading...