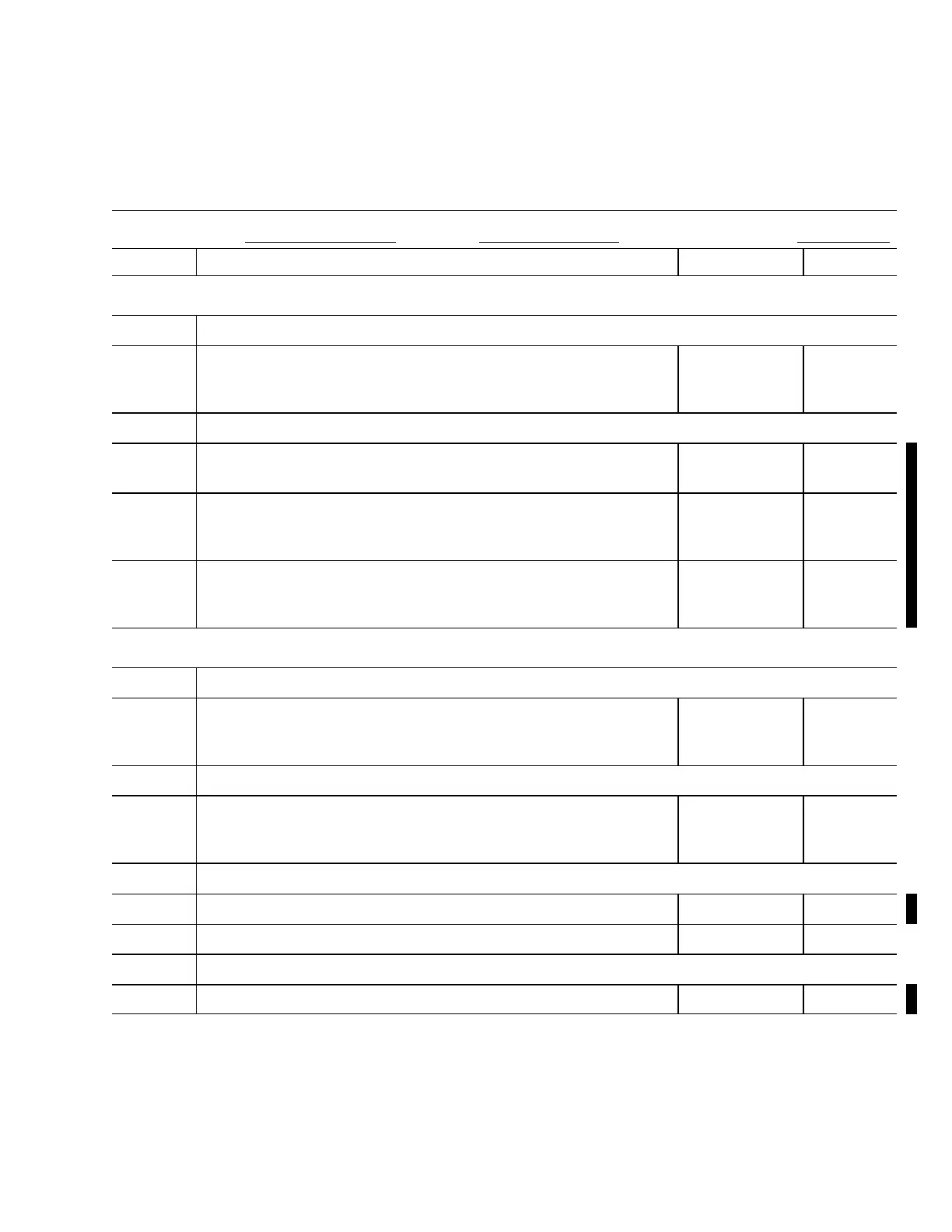

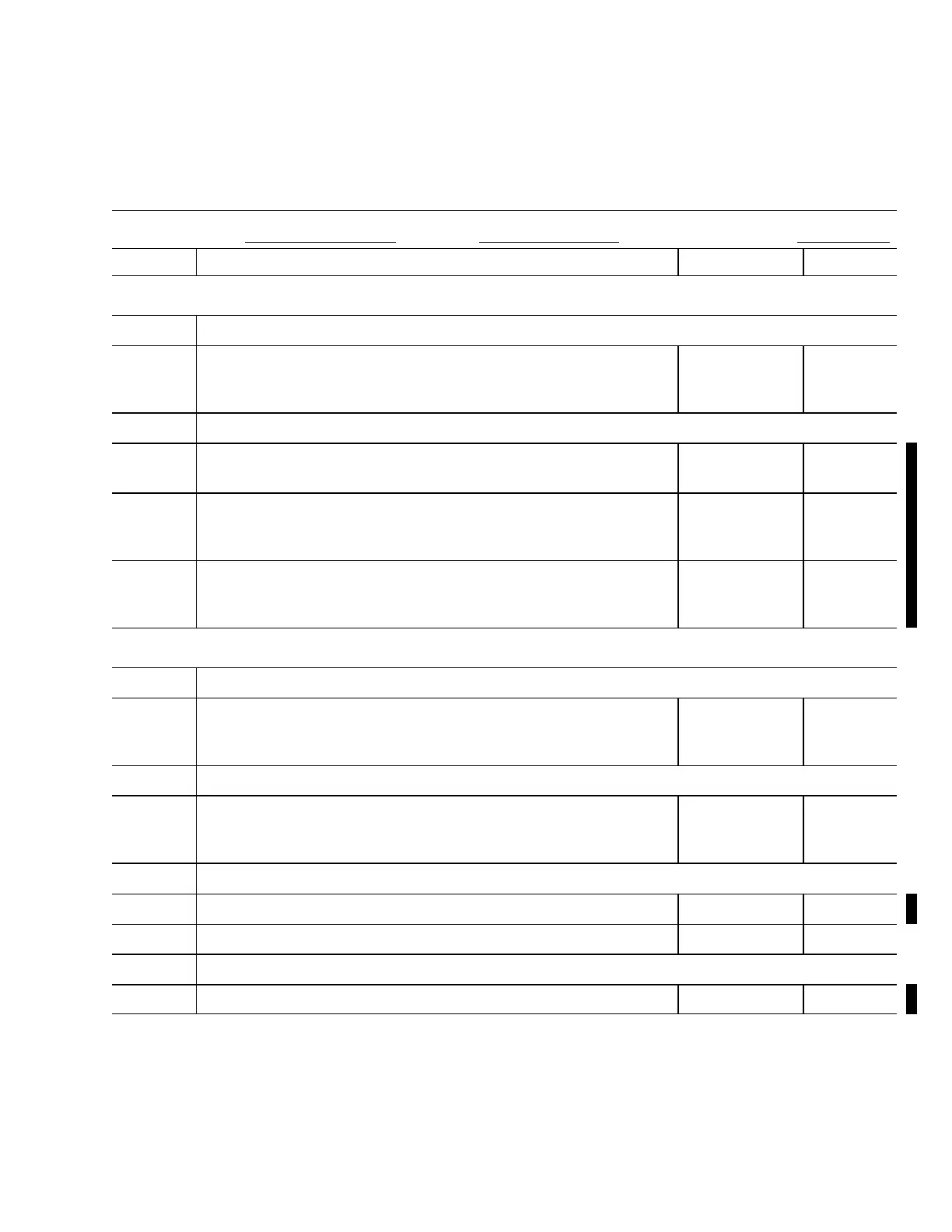

CSP−900RMM−2MD Helicopters, Inc.

Rotorcraft Maintenance Manual

Page 201

Revision 34

05-20-10

CONTINUED AIRWORTHINESS SPECIAL INSPECTIONS

MAINTENANCE PRACTICES

Table 201. Special Inspection − Hourly

Registration No. Serial No. Helicopter Total Hours

Model Requirement RMM Section Initial

50 Hour

Main Rotor: Flexbeam Inspection (PN 900R1103001−109 and −111) [Ref. Note (1)]

900 Do the “Flexbeam Inspection”. Examine main rotor flexbeam for

cracks, delamination, and defects. It is not necessary to remove the

pitchcase or use a borescope.

62−20−00

Main Rotor: Centering Bearing Inspection [Ref. Note (1)]

900 Do the “50−Hour Inspection for the Centering Bearing Assemblies”.

Examine main rotor centering bearings for cracks and defects.

62−20−00

Engine Exhaust: Primary Exhaust Nozzle Assembly (Stainless

Steel) Inspection (for Rotorcraft with PW206A Engines

Installed)

900 Do the “Primary Exhaust Nozzle Assembly (Stainless Steel) Special

Inspection”. Examine primary exhaust nozzle for cracks and

defects.

78−00−00

100 Hour

Main Rotor: Flexbeam Inspection (PN 900R1103001−109 and −111) [Ref. Note (1)]

900 Do the “Flexbeam Inspection”. Examine main rotor flexbeam for

cracks, delamination, and defects. It is necessary to remove

pitchcase or use a borescope.

62−20−00

Main Rotor: Flexbeam Inspection (PN 900R1103001−113 and −115) [Ref. Note (1)]

900 Do the “Flexbeam Inspection”. Examine main rotor flexbeam for

cracks, delamination, and defects. It is not necessary to remove

pitchcase or use a borescope.

62−20−00

Main Rotor:

900 Do the “100−Hour Inspection of the Main Rotor Assembly ”. 62−20−00

900 Do the “Main Rotor Blade Abrasion Strip Inspection”. 62−10−00

Powerplant:

900 Deleted. Moved to Section 05−20−20, Airframe Periodic Inspection.

Loading...

Loading...