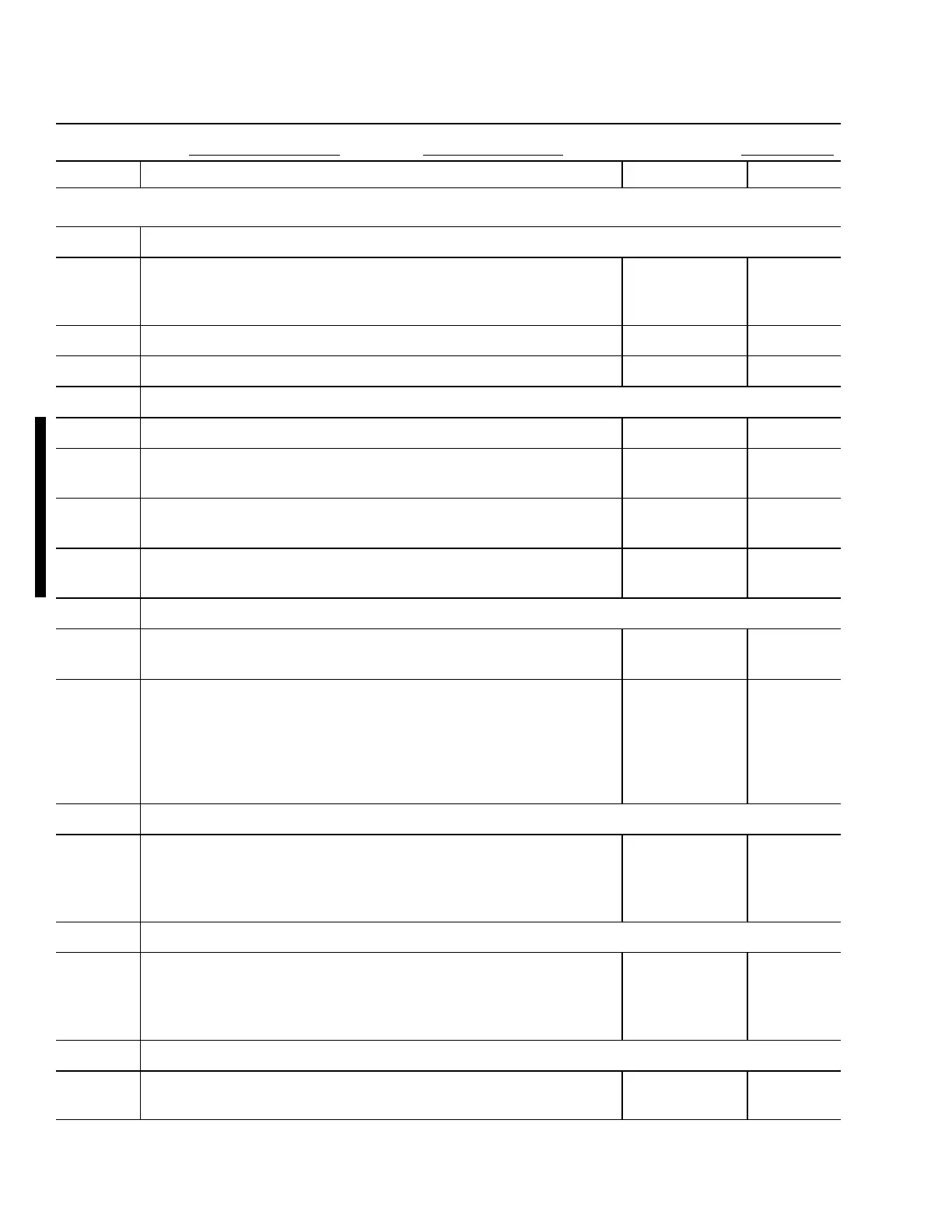

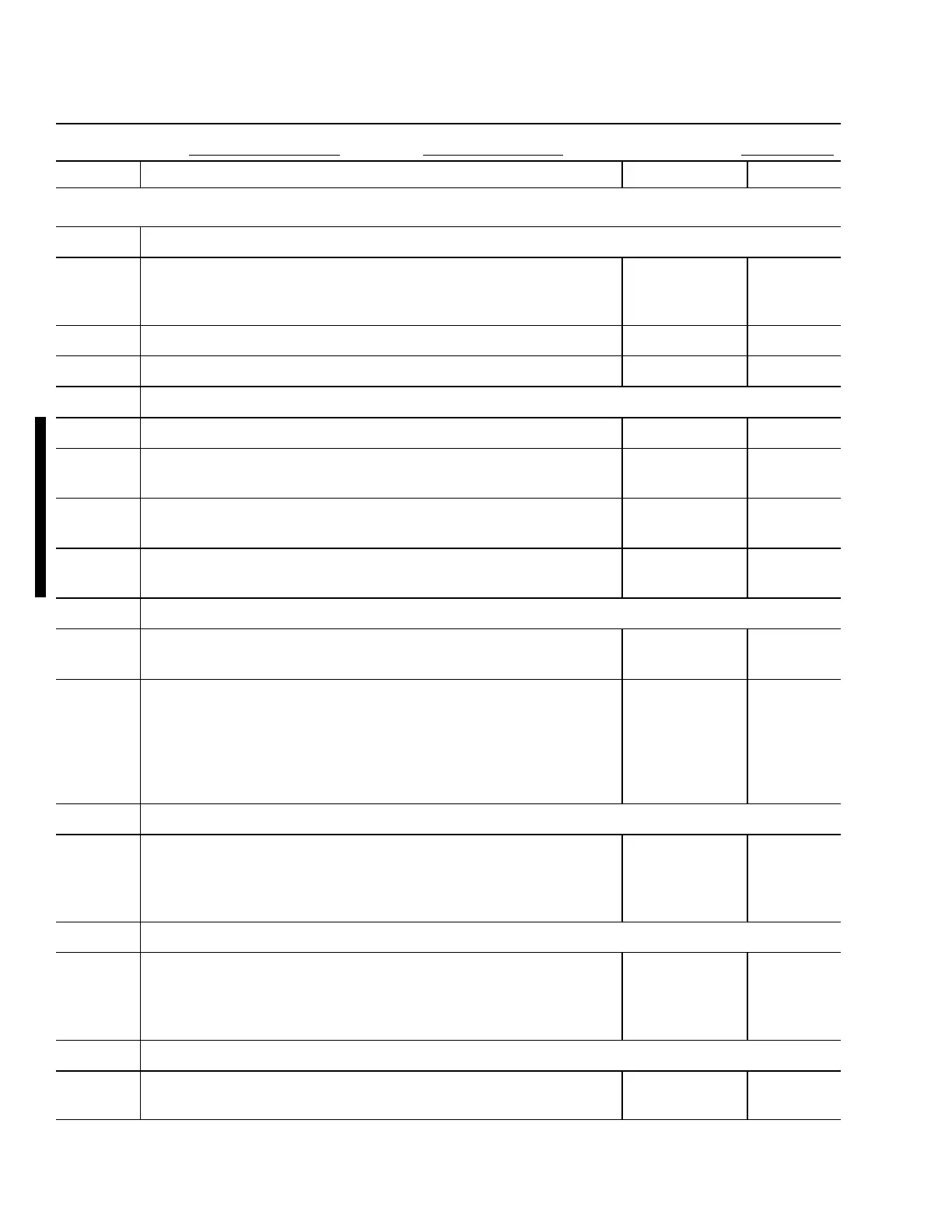

CSP−900RMM−2 MD Helicopters, Inc.

Rotorcraft Maintenance Manual

Page 202

Revision 35

05-20-10

Table 201. Special Inspection − Hourly (Cont.)

Registration No. Serial No. Helicopter Total Hours

Model InitialRMM SectionRequirement

100 Hour

Transmission and Drive System:

900 Do a check of the main rotor drive plate nut torque at the initial

helicopter 100−hour inspection. Refer to Main Rotor Drive Plate Nut

Torque Check.

63−10−00

900 Deleted. Moved to 1000 Hour Special Inspection.

900 Do the transmission Chip Detector Test. 63−20−00

Anti−Torque Assembly:

900 Deleted.

900 Examine the anti−torque fan blades for damage and defects (ref.

Figure 602 and Table 602, Fan Blade Damage Limits).

64−30−01

900 Examine the counterweights on the pitch horns for correct

installation (ref. Inspection, NOTAR® Fan Blade Assembly).

64−30−01

900 Examine fan hub sleeves for damage (ref. Figure 603, Inspection

Areas for Fan Hub, and Table 603, Fan Hub Damage Limits).

64−30−01

Landing Gear:

900 Examine skid tube abrasion strips for wear and correct installation.

Refer to Skid Tube Assembly Inspection.

32−00−00

900 If ground handling wheels have been attached to Station 203

forward ground handling attachment pins:

Examine skid tube upper surface between the aft ground handling

wheel attach pins. Refer to Skid Tube Assembly Inspection and do

a Fluorescent Penetrant Inspection.

32−00−00

and

CSP−SPM

20−90−00

VSCS:

900 Do the “VSCS Operational Test” or VSCS Check. 67−20−00

or

Rotorcraft

Flight Manual

Hydraulic System:

900 Do the Hydraulic System Operational Test (Aircraft Ground Run) or

Hydraulic System Check (ref. the appropriate Rotorcraft Flight

Manual).

29−00−00

and

Rotorcraft

Flight Manual

Fuel:

900 Do the Fuel Cell Longitudinal Baffle Integrity Test (902 CONFIG).

Do the Fuel Transfer System Functional Test (902 CONFIG).

28−00−00

Loading...

Loading...