INTAKE AND EXHAUST – On-vehicle Service

15-5

6. SECONDARY AIR CONTROL SYSTEM

CHECK

(1) Start the engine and let it run at idle speed.

(2) Short-circuit the no. 6 terminal of the engine ECU

connector using a jumper wire and check at this time

that the secondary air valve lifts.

At this time, the engine ECU connector should be

connected.

7. SECONDARY AIR CONTROL SOLENOID

VALVE CHECK

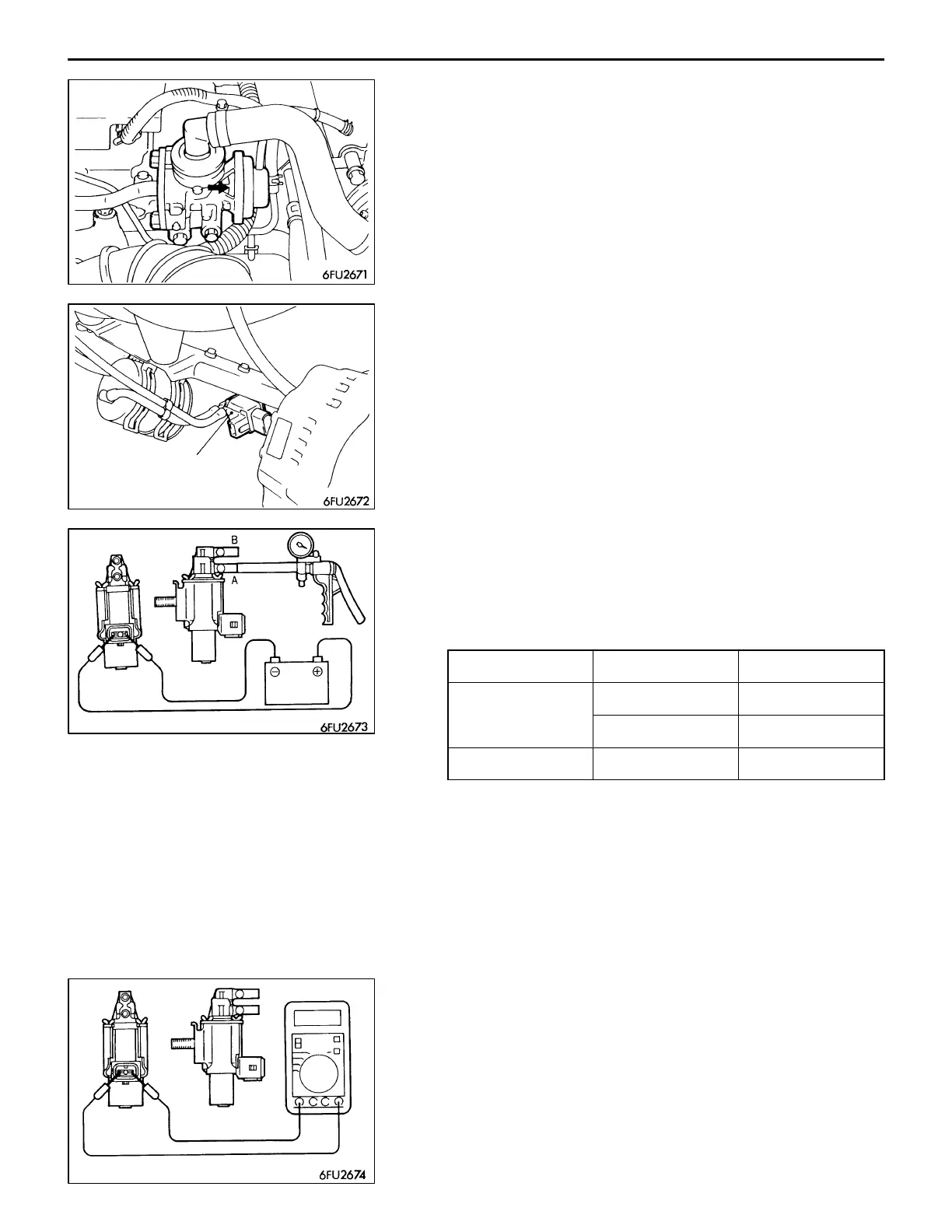

7-1 OPERATION CHECK

(1) Disconnect the vacuum hose (white stripe, yellow stripe)

from the solenoid valve.

(2) Disconnect the harness connector.

(3) Connect a hand vacuum pump to nipple A of the solenoid

valve.

(4) Using jumper wires, connect the solenoid valve terminal

to battery terminals.

(5) Disconnecting and reconnecting the jumper wire on the

(–) terminal side, apply vacuum to check for airtightness.

Jumper wire Nipple B condition Normally

Connected Open Vacuum leaks.

Plugged Vacuum retained.

Disconnected Open Vacuum leaks.

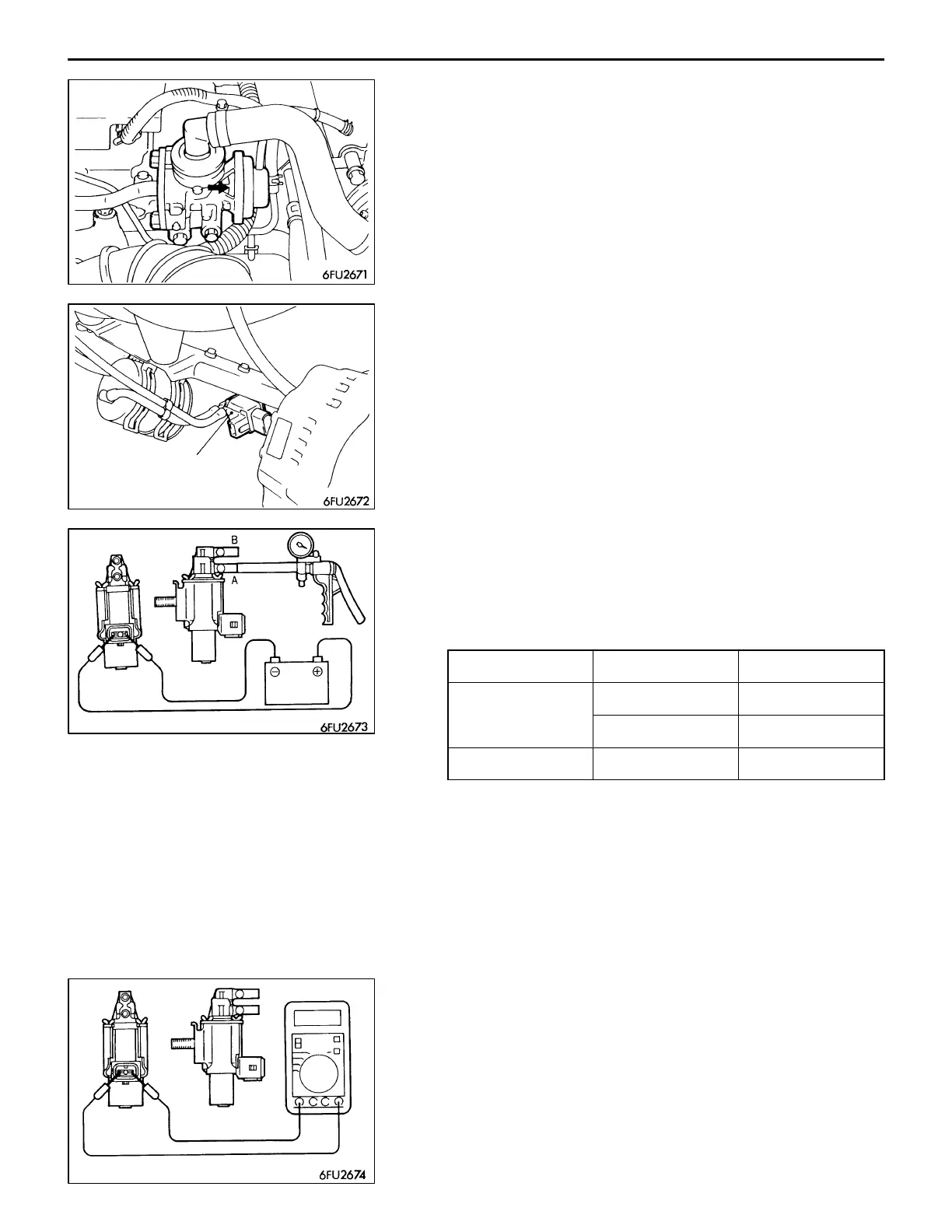

7-2 COIL RESISTANCE CHECK

Measure the resistance across solenoid valve terminals.

Standard value: 28 – 36 Ω (at 20_C)

Secondary air control

solenoid valve

Battery

Loading...

Loading...