MANUAL TRANSMISSION OVERHAUL – Transmission

22B-17

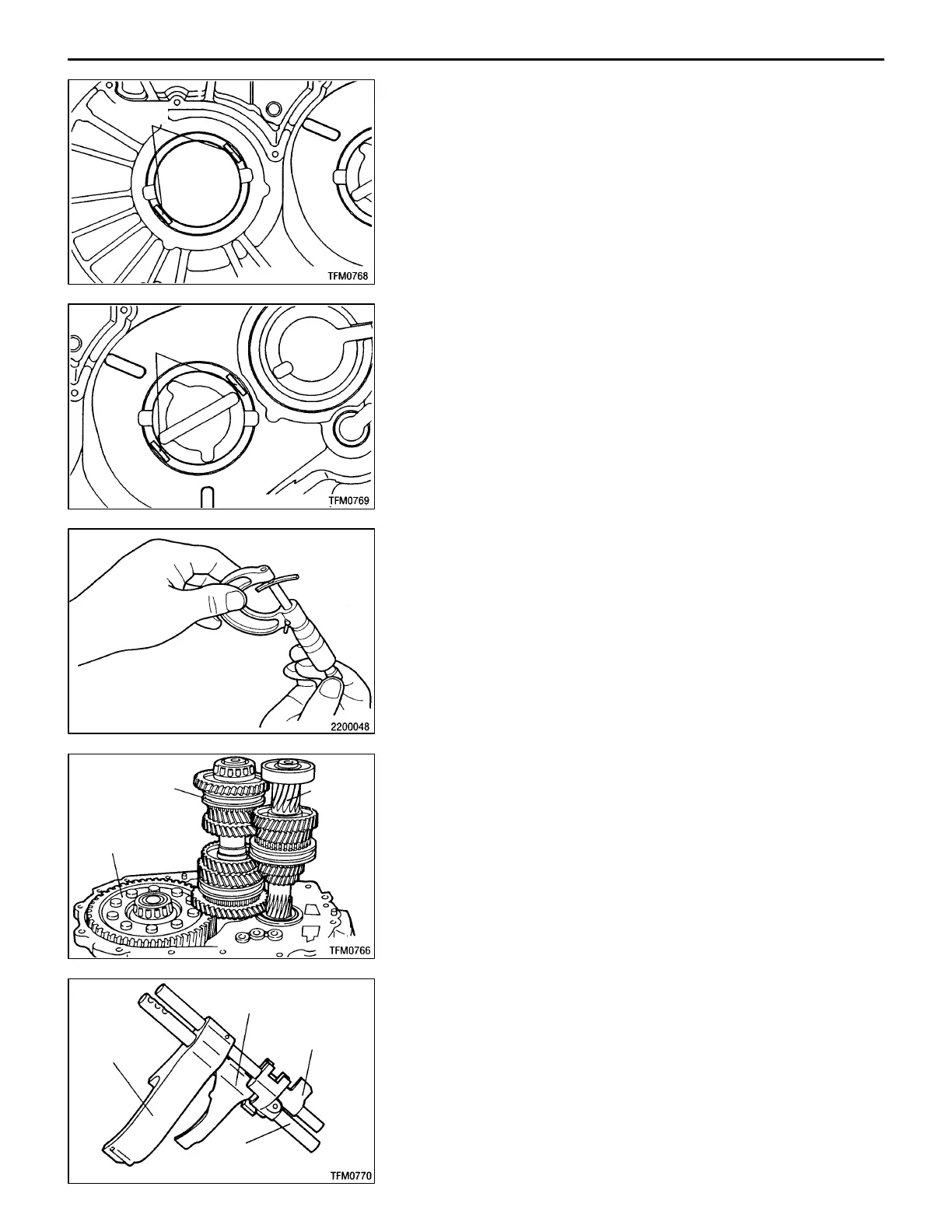

(3) Place two pieces of solder (1.6 mm in diameter and approx.

10 mm in length) on the transmission case at the positions

shown in the illustration.

(4) Install the bearing outer race.

(5) Install the transmission case and tighten the bolts to the

specified torque.

(6) Remove the transmission case. If the solder is not crushed,

repeat the steps (2) through (5) using the solder with

larger diameter.

(7) Measure the thickness of the crushed solder with a

micrometer and select spacers that will provide the

standard end play/preload value.

Standard value:

Input shaft end play 0 – 0.17 mm. . . . . . . . . .

Output shaft end play 0.13 – 0.18 mm. . . . . . . .

Center differential preload 0.05 – 0.11 mm. . . .

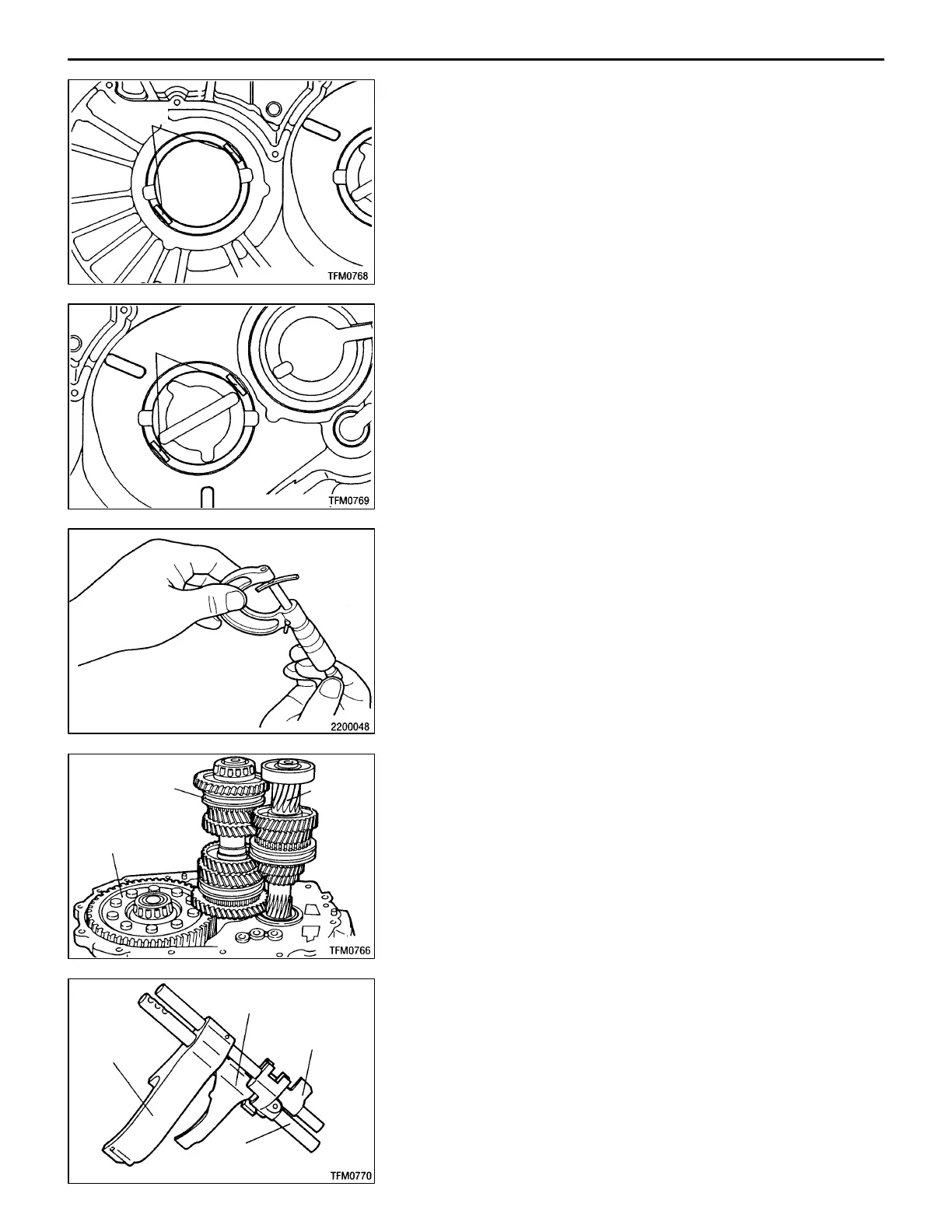

REASSEMBLY SERVICE POINTS

"AA INPUT SHAFT / OUTPUT SHAFT / CENTER

DIFFERENTIAL INSTALLATION

Install the input shaft, output shaft and differential as a unit.

"BA 5TH-REVERSE SPEED SHIFT FORK /

5TH-REVERSE SPEED SHIFT RAIL / 3RD-4TH

SPEED SHIFT FORK / 3RD-4TH SPEED SHIFT

RAIL INSTALLATION

(1) Install the 3rd-4th speed shift rails and fork, and

5th-reverse speed shift rail and fork.

Solders

Solders

Output shaft

Center

differential

Input

shaft

3rd-4th speed

shift fork

5th-reverse

speed shift fork

5th-reverse

speed shift rail

3rd-4th speed

shift rail

Loading...

Loading...