255

Application Section 2-6

2-6-1 Communications Procedure

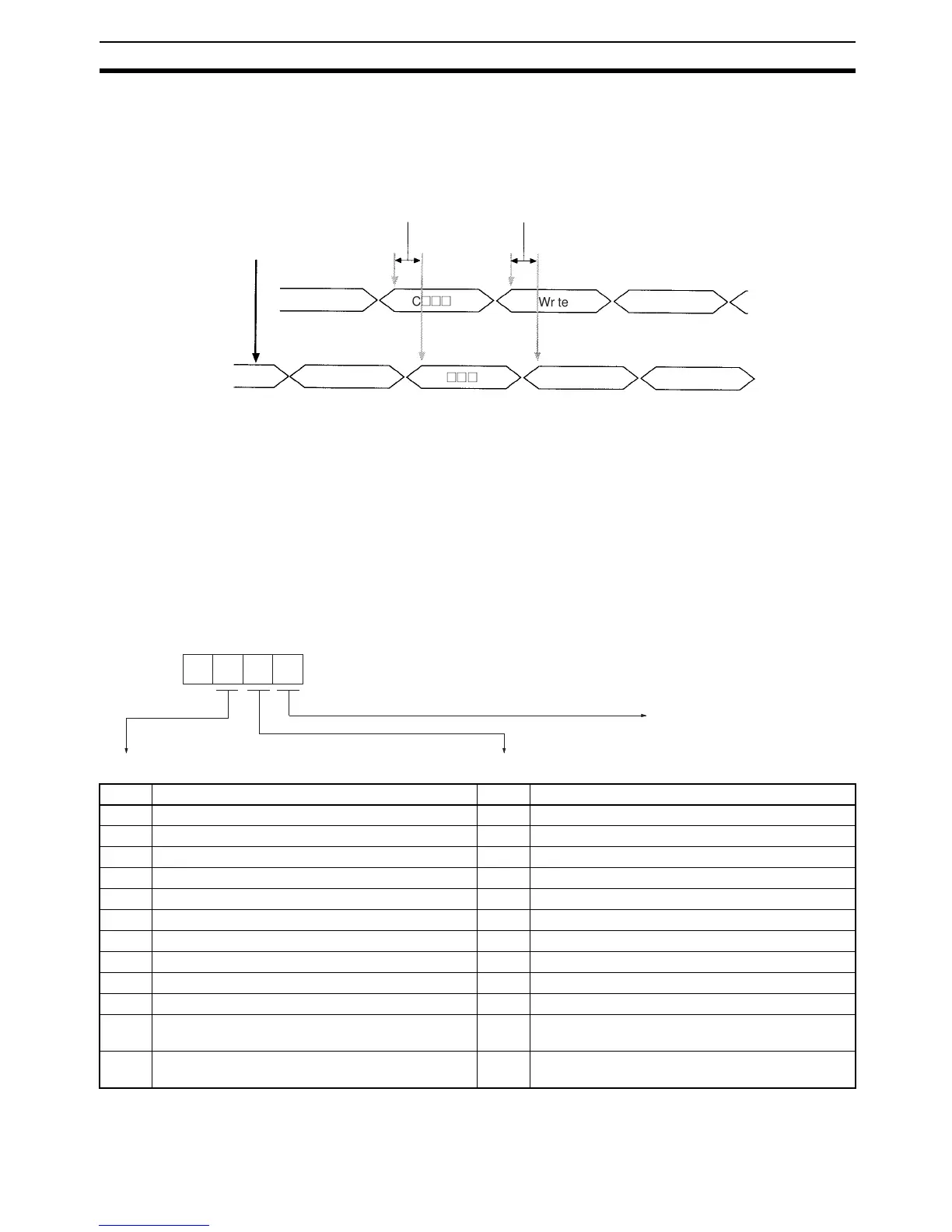

The following diagram illustrates the procedures used to set parameters, mon-

itor data, and read data.

Note No commands are set at startup.

1,2,3... 1. Output word: An I/O allocation command (C@@@) is set to specify the loop

and the items to be set and monitored.

2. Input word: The I/O allocation command set in the output word will be set

by the system as a “Command Acknowledged Flag” to indicate that the

command has been acknowledged.

3. Output word: The write data for the I/O allocation command set in 1. is set.

4. Input word: After the data specified in 3. has been set, the data specified

to be monitored in 1. will be set by the system. This also functions as a

“Write Completed Flag” to indicate that the write operation has been com-

pleted.

Output

word

Input

word

Power ON

Initialization

Read data

Initialization

completed

FFFF

0000

C

(((

C

(((

Write data

60 ms max. 60 ms max.

(1) (2) (3) (4)

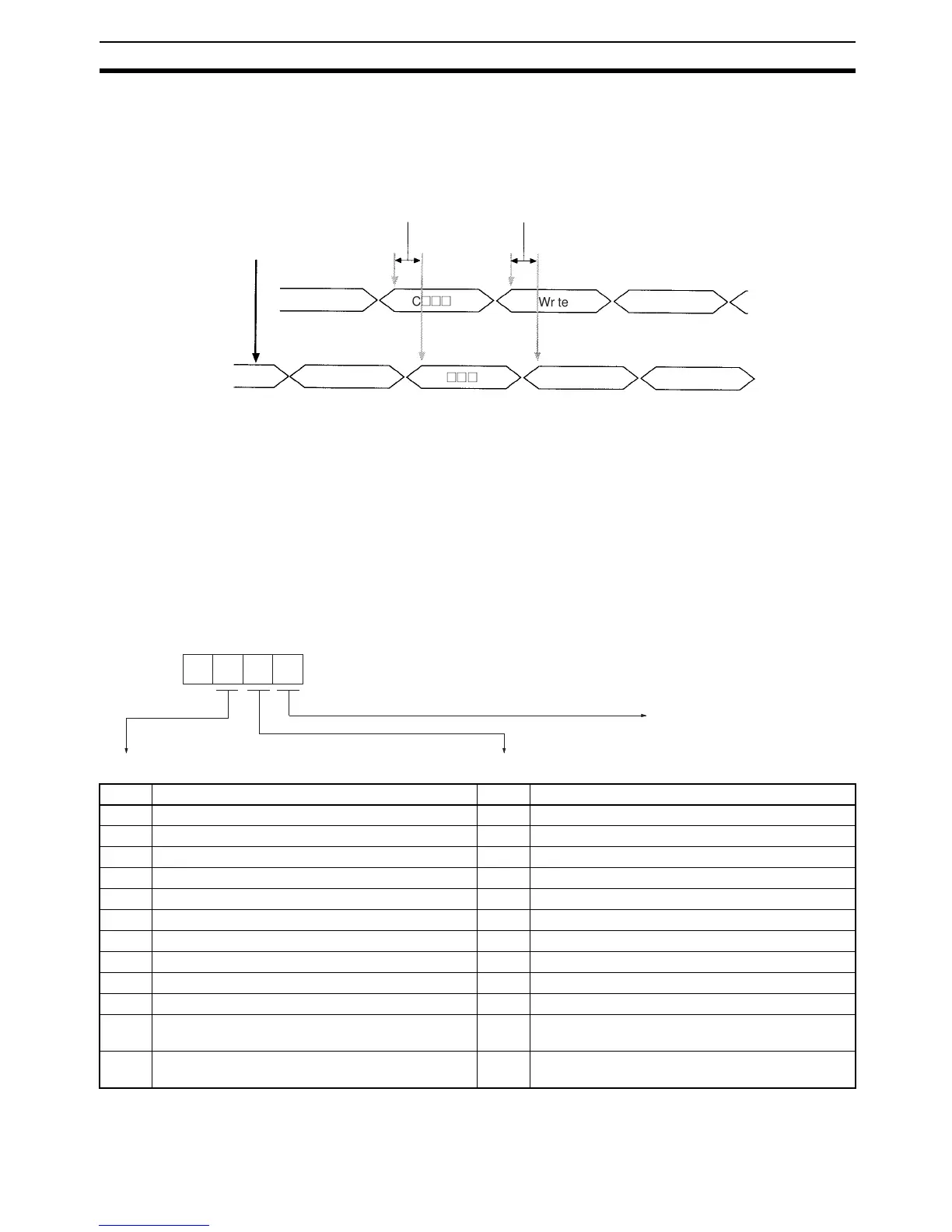

Value Item to be set Value Item to be monitored

0 Set point 0 Set point

1 Proportional band (for advanced PID) 1 Proportional band (for advanced PID)

2 Integral time (for advanced PID) 2 Integral time (for advanced PID)

3 Derivative time (for advanced PID) 3 Derivative time (for advanced PID)

4 Hysteresis (for ON/OFF control) 4 Hysteresis (for ON/OFF control)

5 Control cycle (for advanced PID or manual control) 5 Control cycle (for advanced PID or manual control)

6 Input shift value 6 Input shift value

7 No item set (See note 2.) 7 Process value

8 Manual manipulated variable 8 Manipulated variable

9 Do not set. 9 Status

A Heater burnout alarm setting (only for models with

heater burnout alarms)

A Heater burnout alarm setting (only for models with

heater burnout alarms)

B Do not set. B Heater current (only for models with heater burnout

alarms)

C

Item To Be Set Item To Be Monitored

Output word

Loop number: 1 to 4

Loading...

Loading...