Section 05: COOLING SYSTEM

PA1562

9

The coolant provides a medium for heat transfer

and controls the internal temperature of the

engine during operation. In an engine having

proper coolant flow, some of the combustion

heat is conveyed through the cylinder walls and

the cylinder head into the coolant. Without

adequate coolant, normal heat transfer cannot

take place within the engine, and engine

temperature rapidly rises. Coolant must

therefore be carefully selected and properly

maintained.

Select and maintain coolant in order to meet the

following basic requirements:

• Provide for adequate heat transfer.

• Provide protection from cavitation damage.

• Provide a corrosion and erosion resistant

environment within the cooling system.

• Prevent formation of scale or sludge

deposits in the cooling system.

• Be compatible with the cooling system hose

and seal materials.

• Provide adequate freeze protection during

cold weather operation.

When freeze protection is required, a mixture of

suitable water and antifreeze containing

adequate inhibitors will provide a satisfactory

coolant fluid.

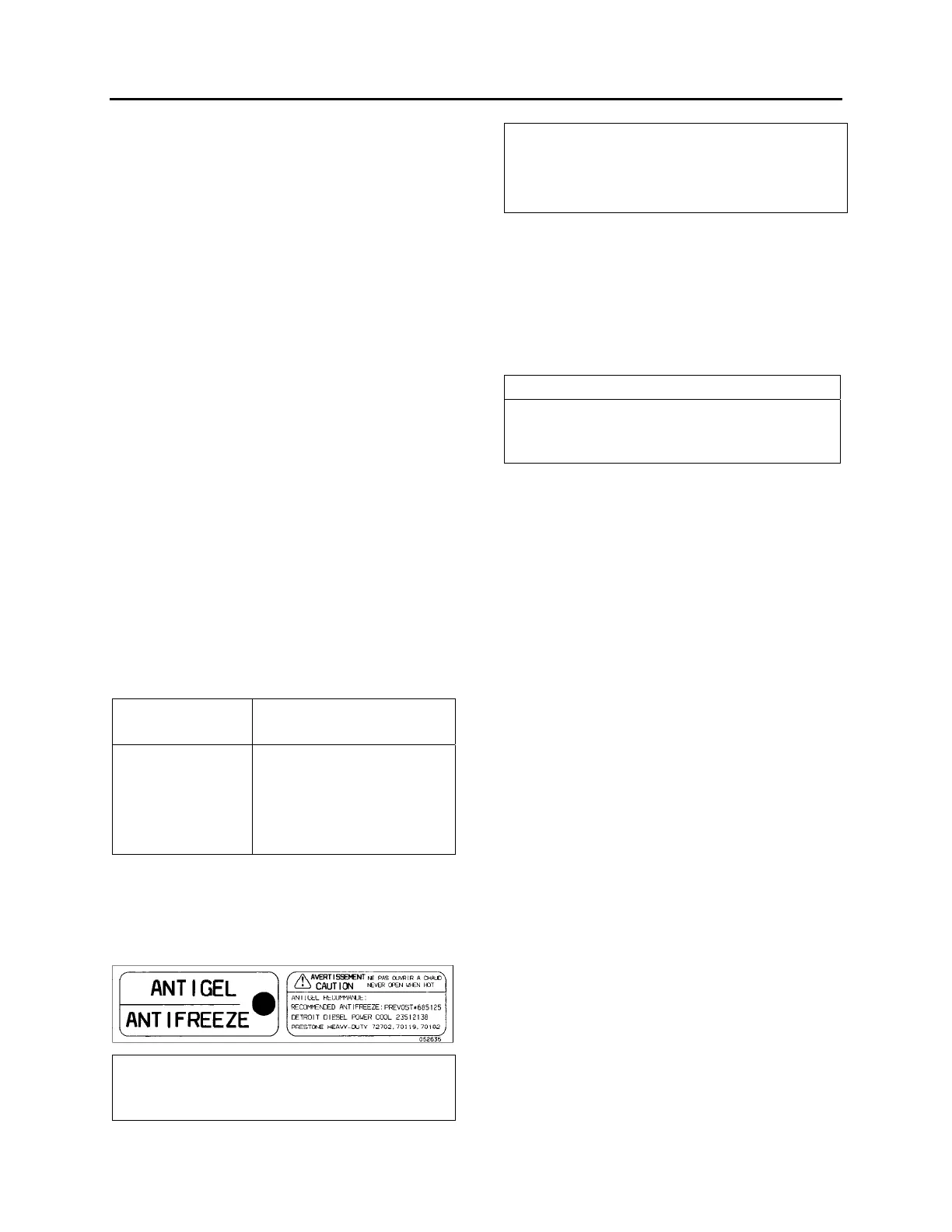

Freeze protection

down to:

percentage of antifreeze in

mixture

-13°F (-25°C)

-22°F (-30°C)

-36°F (-385°C)

-51°F (-46°C)

40%

46%

54%

60%

5.5 COOLANT RECOMMENDATIONS FOR

DETROIT DIESEL SERIES 60 ENGINE

A decal (052635) located on the surge tank

provides information on recommended coolants.

05104

Recommended phosphate free coolants for

Detroit Diesel Series 60 engine:

• Prevost #685125;

• Detroit Diesel “DDC Power Cool” (P/N

23512138);

• Prestone AF977 (bulk), 72702 (3.78 L),

70119 (205L), 70102 (4L).

Combining suitable water with reliable inhibitors

satisfies the first five requirements. When freeze

protection is required, a solution of suitable

water and antifreeze containing adequate

inhibitors will provide a satisfactory coolant fluid.

Ethylene glycol-based antifreeze is

recommended for use in Series 60 engines. The

cooling system capacity is 24 US gal (91 liters).

NOTE

In general, antifreeze does not contain

adequate inhibitors. For this reason,

supplemental coolant additives are required.

For a complete overview of engine coolants

used with Detroit Diesel Engines, refer to

"Coolant Selections" For Engine Cooling

Systems Guide at the end of this section

(#7se298).

1. Always use recommended antifreeze,

inhibitor and water at proper concentration

levels. A 50% coolant/water solution is

normally used as factory fill. Antifreeze

concentration over 70% is not recommended

because of poor heat transfer capability,

adverse freeze protection and silicate

dropout. Antifreeze concentration below 30%

offers little freeze, boilover or corrosion

protection.

2. Use only ethylene glycol antifreeze meeting

the Detroit Diesel #7se298 or TMC RP-329

“Type A” formulation.

3. Use an antifreeze solution year-round for

freeze and boil-over protection. Seasonal

changing of coolant from an antifreeze

solution to an inhibitor/water solution is

recommended.

4. Pre-mix coolant makeup solutions at proper

concentrations before adding to the cooling

system.

5. Maintain the prescribed inhibitor strength

levels as required.

6. Do not mix different base inhibitor packages.

7. Always maintain proper coolant level.

Loading...

Loading...