Section 11: REAR AXLES

PA1562

2

1. DRIVE AXLE

1.1 DESCRIPTION

The Meritor drive axle is equipped with a single

reduction standard carrier mounted in front of

the axle housing. The carrier consists of a

hypoid drive pinion, a ring gear set and gears in

the differential assembly.

FIGURE 1: DRIVE AXLE 11019

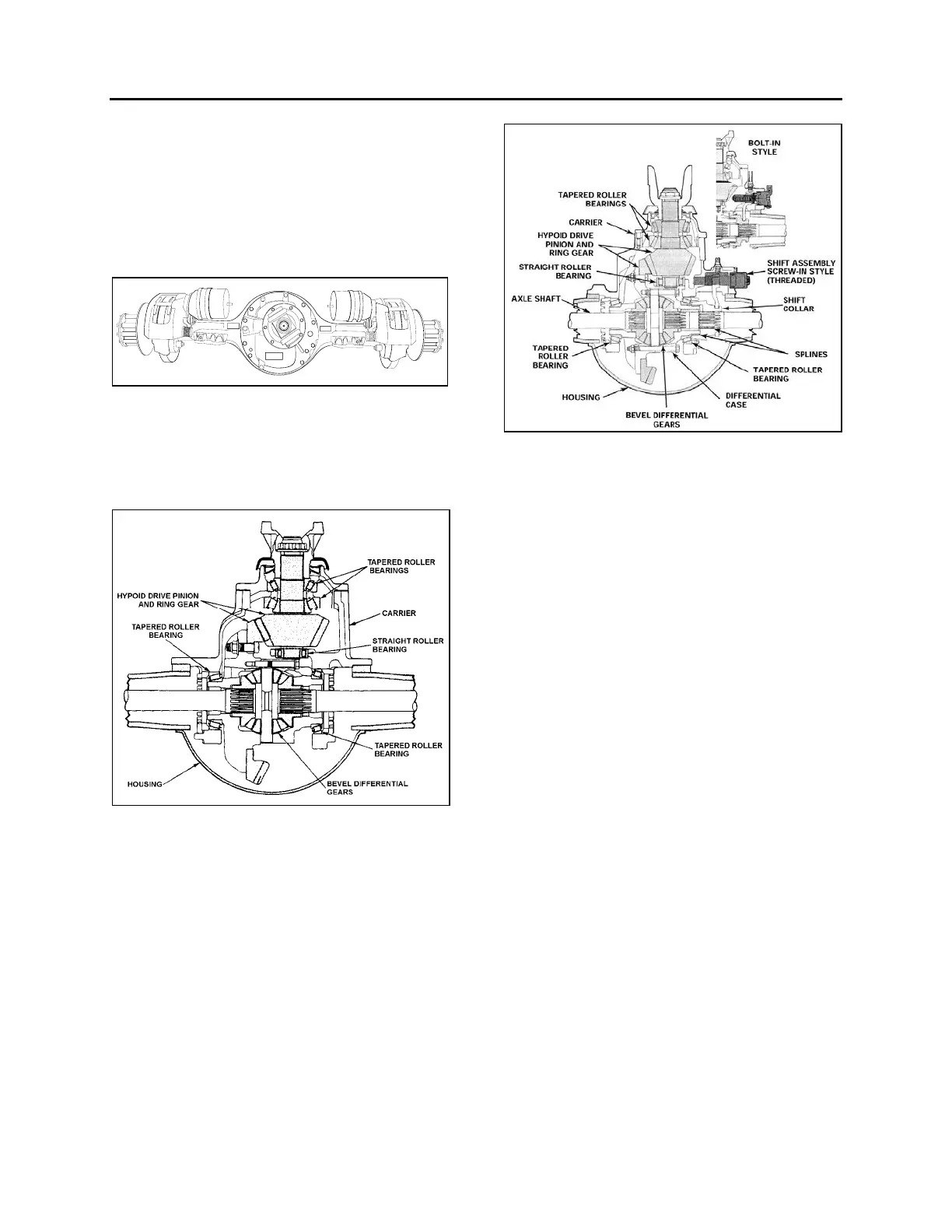

A straight roller bearing (spigot) is mounted on

the head of the drive pinion. All other bearings in

the carrier are tapered roller bearings. When the

carrier operates, there is a normal differential

action between the wheels all the time.

FIGURE 2: DIFFERENTIAL ASSEMBLY 11024

Several speed ratios are available for the drive

axle. These ratios depend upon the motor and

transmission. Also, special applications may

suggest slightly different gear ratios.

1.2 DCDL (DRIVER-CONTROLLED MAIN

DIFFERENTIAL LOCK)

Meritor Single-reduction carriers with driver-

controlled main differential lock (DCDL) have the

same type of gears and bearings as the

standard-type carriers. The differential lock is

operated by an air actuated shift assembly that

is mounted on the carrier.

FIGURE 3: DRIVER-CONTROLLED DIFFERENTIAL LOCK

11028

1.3 DRIVE AXLE LUBRICATION

Additional lubrication information is covered in

the Meritor Technical Bulletin TP-9539:

“Approved Rear Drive Axle Lubricants” annexed

to this section. During initial stage of normal

operation, tiny metal particles originating from

moving parts can be found on mating surfaces.

These particles are carried by the lubricant

through the assembly and act as lapping

compound, which accelerates wear of all parts.

To ensure maximum life of the differential and

prevent premature failure, the original "factory

fill" lubricant should be drained. Change break-in

oil before 3,000 miles (4 800 km) of initial

operation (drain the unit while it is still warm

from operation), in accordance with the

lubrication and servicing schedule.

Change differential oil and clean the breathers,

magnetic fill and drain plugs, every 100,000

miles (160 000 km) or once every two years,

whichever comes first.

Use Multigrade gear oil MIL-L-2105-D. Use the

75W90-gear oil for northern climates and the

80W140 for southern climates. In extreme

conditions, or for better performance, fill with

synthetic gear oil. Check oil level and add (if

necessary) every 6,250 miles (10 000 km) or

twice a year, whichever comes first (Fig. 4).

Loading...

Loading...