8

3

Dimension

checks

3-4

Open side circumference check

WARNING

Wheels that have been subjected to high pressure tire and rim

separation or excessive heat damage may no longer have sufficient dimension

and contour to retain the tire bead while under pressure.

Exploding wheel/tire assembly can cause serious injury or death.

Immediately and permanently remove from service any wheel that has been

exposed to high pressure tire and rim seperation or excessive heat.

Ball tapes used for measuring wheel circumference can be purchased from the Tire and Rim Association, Inc.,

175 Montrose West Avenue, Copley, Ohio 44321. (330) 666-8121 or at www.rma.org. For instructions on

proper use of ball tape, reference the current Tire and Rim Association yearbook.

Measure the circumference of the bead seat on the open side (see illustration

to left) with a ball tape.

The circumference of the bead seat on the open side of the wheel should

be checked at each tire change. The open side is the side opposite the disc

face. In the case of center flange wide base wheels, or wheels with insets less

than 3 inches, both rim flanges should be checked. Any wheel should be

inspected prior to mounting. If the circumference of the bead seat does not

match the required dimension as indicated by the TRA certified ball tape,

immediately and permanently remove the wheel from service.

WARNING

THIS INSPECTION TECHNIQUE ONLY APPLIES TO DUAL OR DISC FACED WHEELS

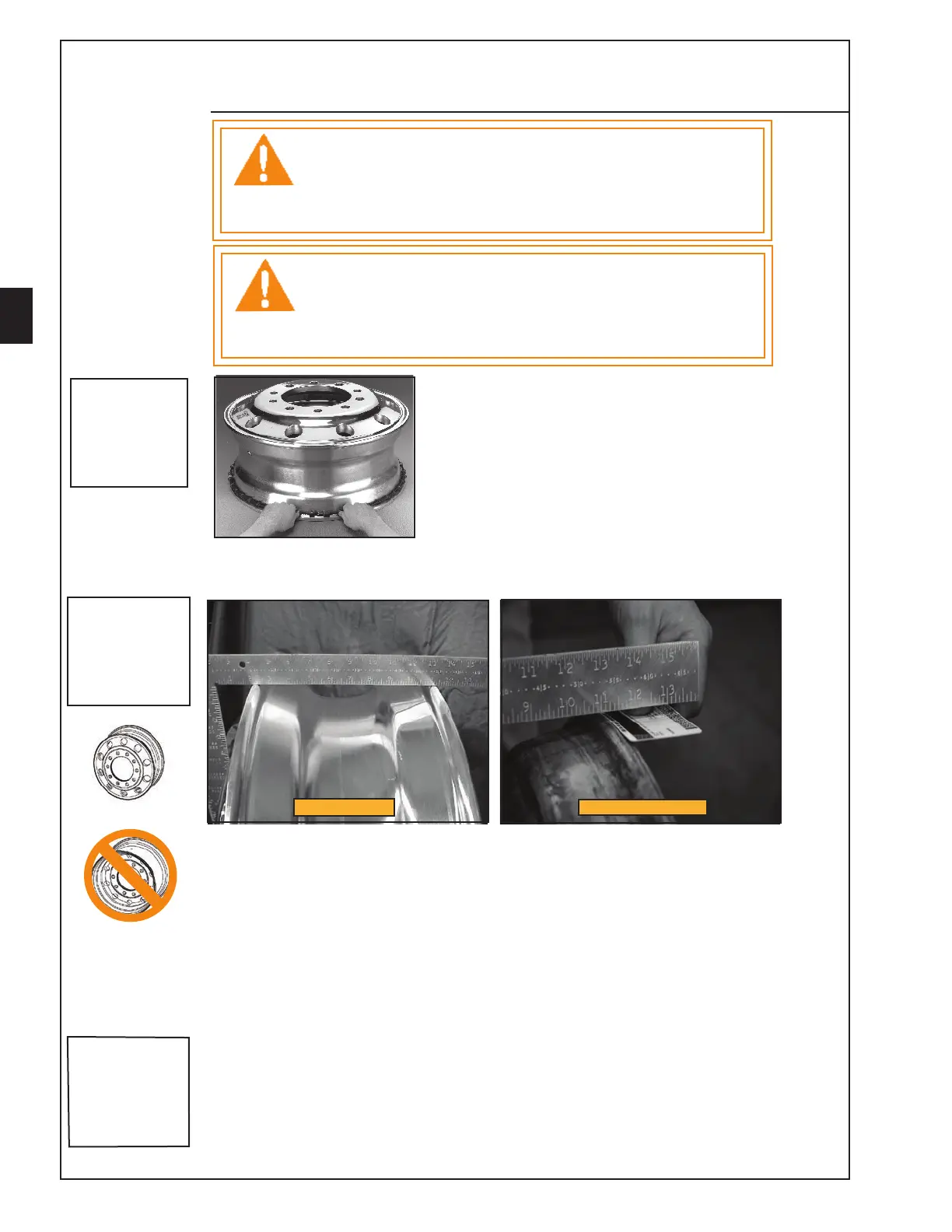

Check all wheels at each tire change for proper contour of the open side of the rim. Place the long leg of a

carpenters square across the center of the disc side of the wheel. Extend the short leg across both rim flanges of the

wheel as shown above. Repeat this process at four equidistant points around the wheel.

The short leg should touch both rim flanges at each point. If a distance greater than the thickness of a credit

card (or .030 in. or .76mm feeler gauge) appears between the short leg and the rim flange, the wheel should be

removed from service and scrapped.

Best Inspection

Method

Photo to the right

shows the TRA Ball

Tape

2nd Best Inspection

Method

If a ball tape is

unavailable

Photo above shows carpenter square even on

both bead seats.

Photo above shows and undersized wheel

that you can clearly place a credit card

(approximately .030 in. or .76mm) between

the square and the wheel.

ACCEPTABLE

UNACCEPTABLE

WARNING

WARNING Wheels that have been run flat or have other physical damage may no longer

have sufficient dimension and contour to retain the tire bead while under pressure.

Rims that lack proper dimension and contour can lead to explosive separation of the tire

and rim, causing serious injury or death.

Any wheel that has been in service must be inspected prior to mounting. Follow

dimension check procedures described in this section during each wheel inspection.

If a ball tape or carpenters square is unavailable, roll the unmounted wheel, without a tire, a minimum of 10 feet

over a smooth, flat, level, clean surface such as asphalt or concrete pavement. Any deviation from rolling in a

straight line is an indication of a potential lack of proper dimension and contour. Remove the wheel from service

until it can be properly checked with a ball tape.

3rd Best Inspection

Method

Rolling wheel as

described on this

page.

IF YOU DO NOT FULLY UNDERSTAND ANY OF THESE INSPECTION METHODS AS DESCRIBED

IN THIS SECTION CONTACT ALCOA AT 800-242-9898 FOR CLARIFICATION.

Dual wheel

Non-Dual wheel

Loading...

Loading...