Section 12: BRAKE AND AIR SYSTEM

PA1562

11

10.1.1 Compressor Removal and Installation

1. Exhaust compressed air from air system by

opening the drain valve of each air tank.

2. Drain the engine cooling system. See

Section 5: "Cooling System".

3. Identify and disconnect all air, coolant and

oil lines from the compressor assembly.

4. Access the compressor by the engine R.H.

side compartment. Remove the four com-

pressor mounting bolts and the two fuel

pump support bracket bolts.

5. Slide air compressor rearward to disengage

the hub from coupling. Remove the air

compressor.

Reverse removal procedure for installation.

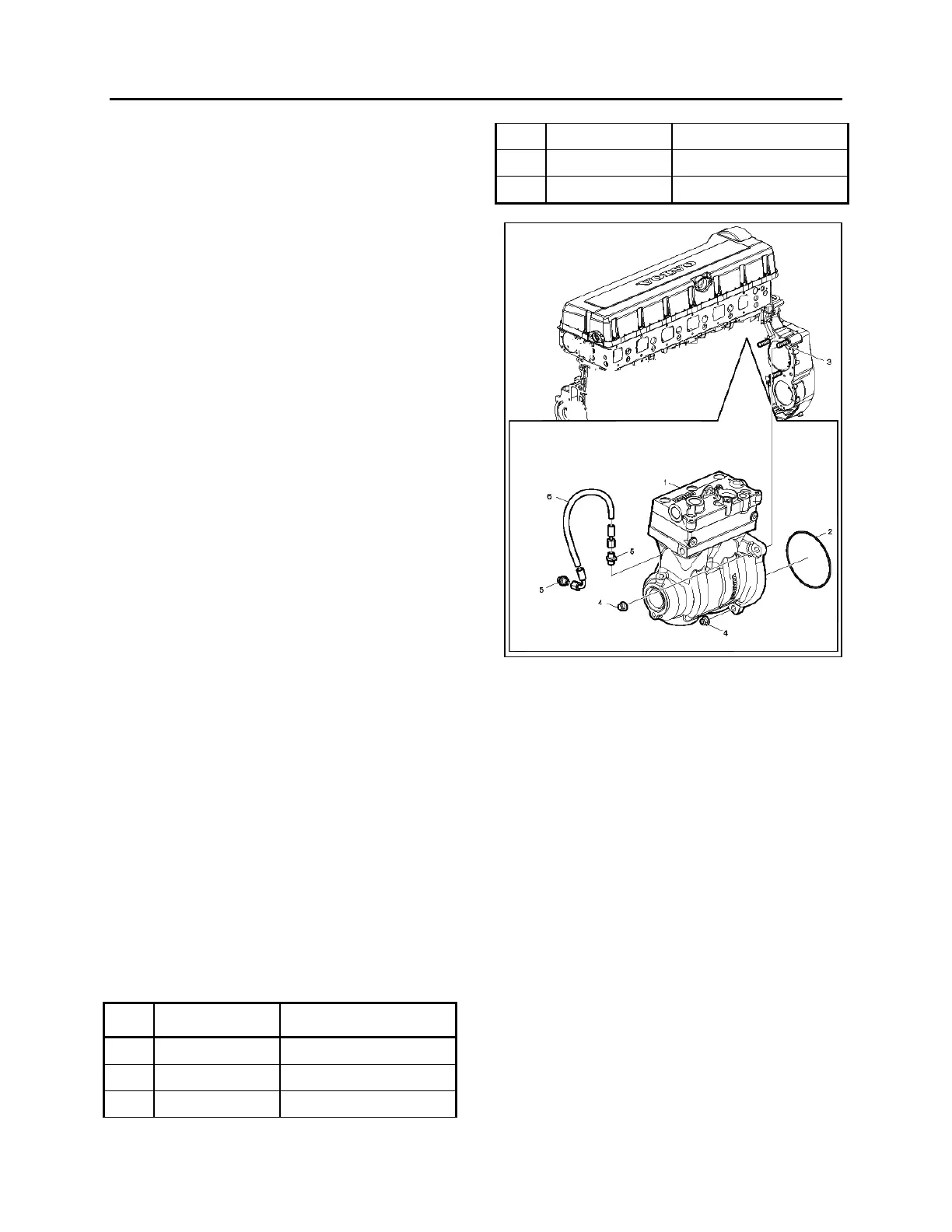

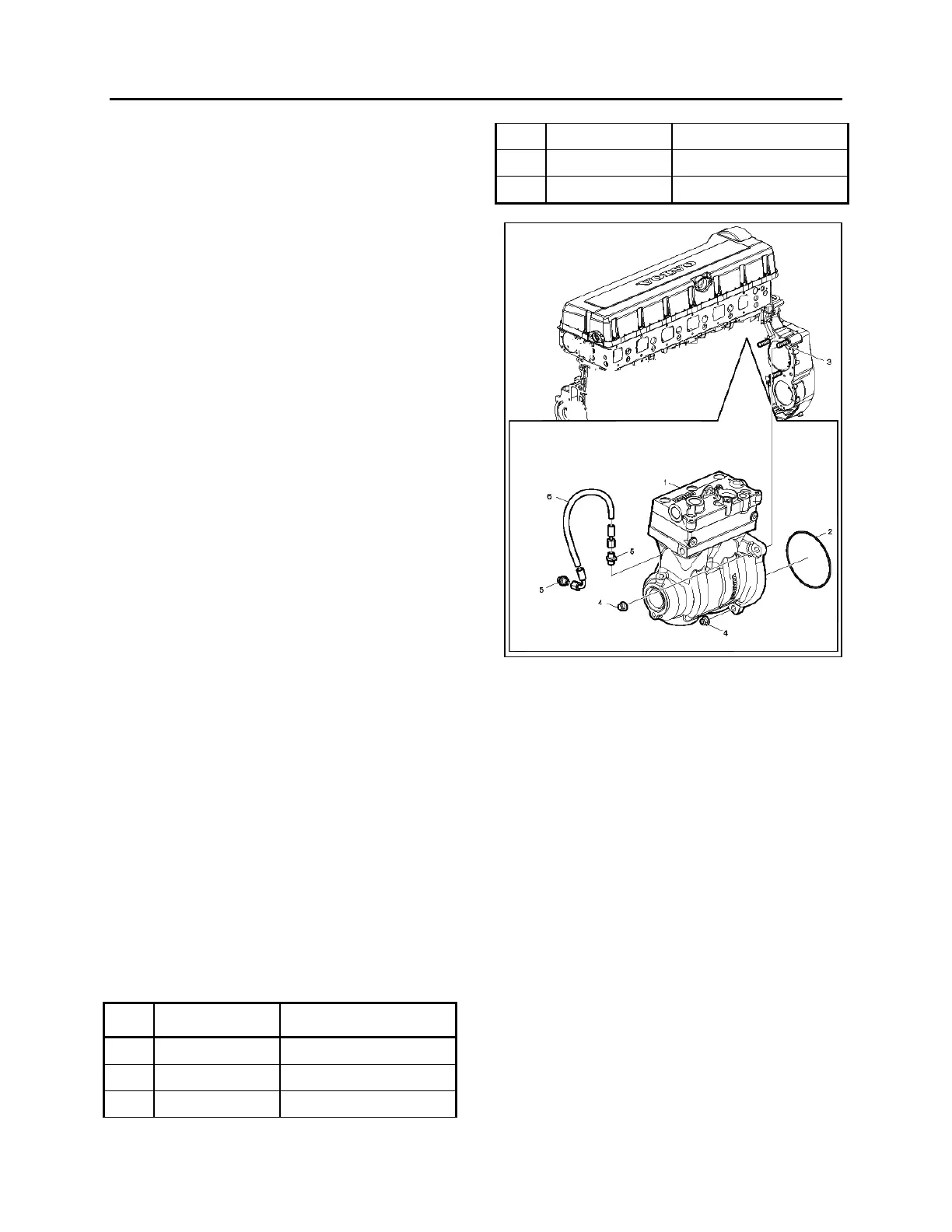

10.2 WITH VOLVO D13 ENGINE

The Wabco System Saver 636 Twin Cylinder air

compressor is located on the alternator side of

the engine, at the flywheel end (Fig. 10). Its

function is to provide and maintain air under

pressure to operate devices in brake and air

systems.

The compressor is driven by the ring gear, and

is water cooled. Engine coolant is fed to the

compressor through a flexible hose tapped into

the block water jacket and connected to the rear

of the compressor. Coolant returns from the top

of the compressor (governor side) through a

flexible hose to the engine pump.

The air is taken from the air intake manifold and

entered in the top of the compressor. The

compressed air is pushed into the discharge line

located on side of the compressor, which sends

air to the air dryer. Lubricating oil is supplied to

the compressor by a line from the cylinder block

oil gallery connected to the air compressor.

Lubricating oil returns to the engine crankcase

through the air compressor drive assembly.

Maintenance and repair information on the

Wabco 636 Twin Cylinder air compressor is

supplied in the applicable booklet annexed at

the end of this section.

Item Description Notes

1 Air Compressor Wabco 636

2 O’Ring

3 Stud (3) M12

4 Flange Nut (3) Torque to 15lb-ft (20 Nm)

5 Nipple (2)

6 Hose Assembly

FIGURE 10: AIR COMPRESSOR LOCATION 03061

10.2.1 Compressor Removal and Installation

1. Exhaust compressed air from air system by

opening the drain valve of each air tank.

2. Drain the engine cooling system. See

Section 5: "Cooling System".

3. Access the compressor by the engine R.H.

side compartment. Identify and disconnect

all air, coolant and oil lines from the

compressor assembly.

4. Remove the three compressor flange

mounting nuts.

5. Slide air compressor rearward to disengage

the hub from coupling. Remove the air

compressor.

Remove and retain the oil supply tube that

runs between the compressor and the

engine

Reverse removal procedure for installation.

Loading...

Loading...