Assembly Preparation

Wash all parts in clean, OSHA approved solvent. Air blow-dry them only.

Because they are flammable, be extremely careful when using any solvents. Even a small

explosion or fire could cause injury or death.

Wear eye protection and be sure to comply with OSHA or other maximum air pressure

requirements.

Tools Required

Lbf•ft Torque wrench

Press

Ratchet

Retaining ring pliers

Sockets: 1 1/4", 9/16", 7/8" deep well

Vise

Materials Required

Grease (petroleum base chassis lube)

Assembly

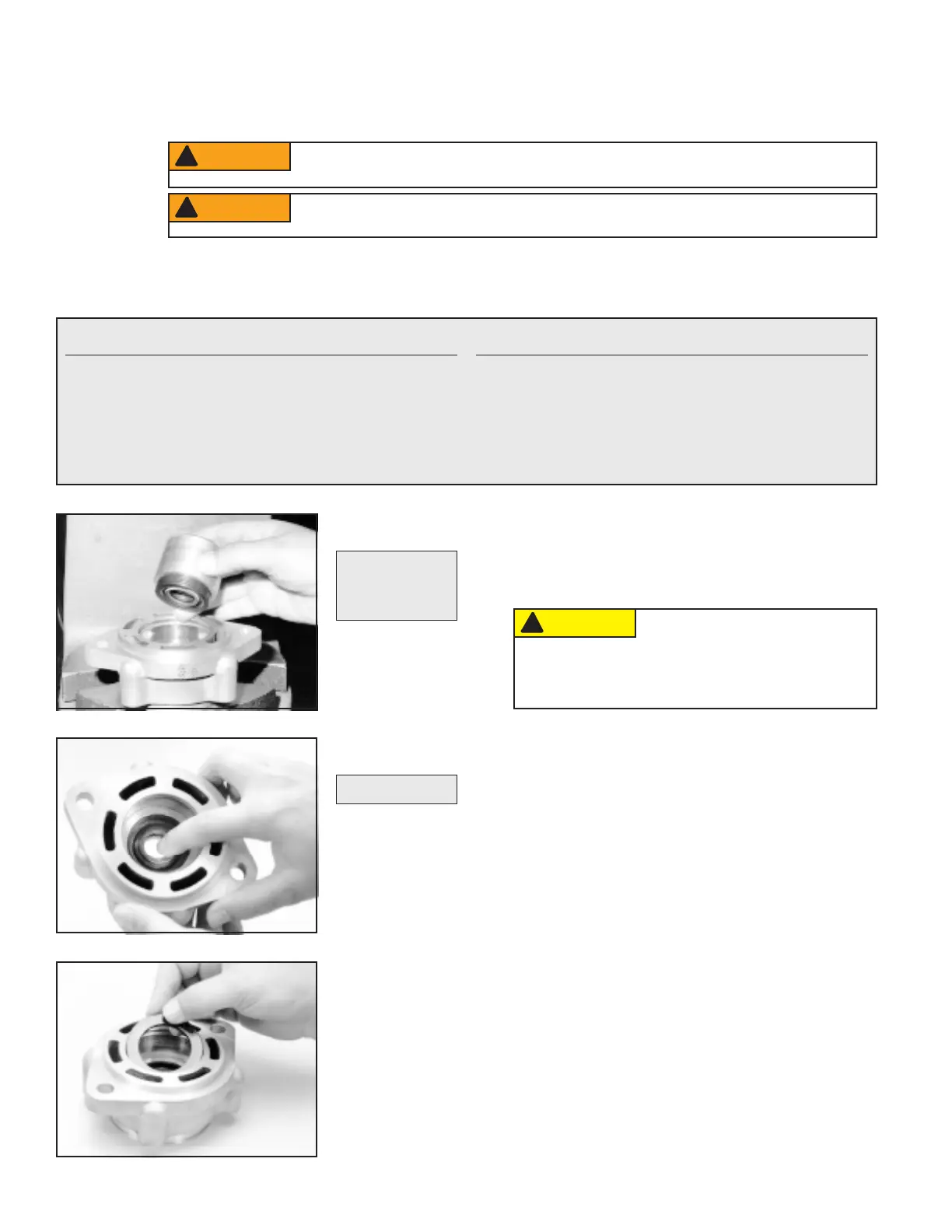

1. Grease the outside diameter of the shaft seal (23)

with the special grease provided, and press it into

the cover, with the lettered side facing toward the

needle bearing. The installed seal should be flush

with or just below the sealing surface on the cover.

Press in shaft seal

Press

Suitable size

tool or socket

Make sure the press is clean and

free of debris so as not to damage

the face of the cover on which the bottom plate rests. If

damage occurs to the cover, the pump will not function

properly.

2. Grease the inside diameter of the shaft seal (23)

with the special grease provided.

Grease shaft seal

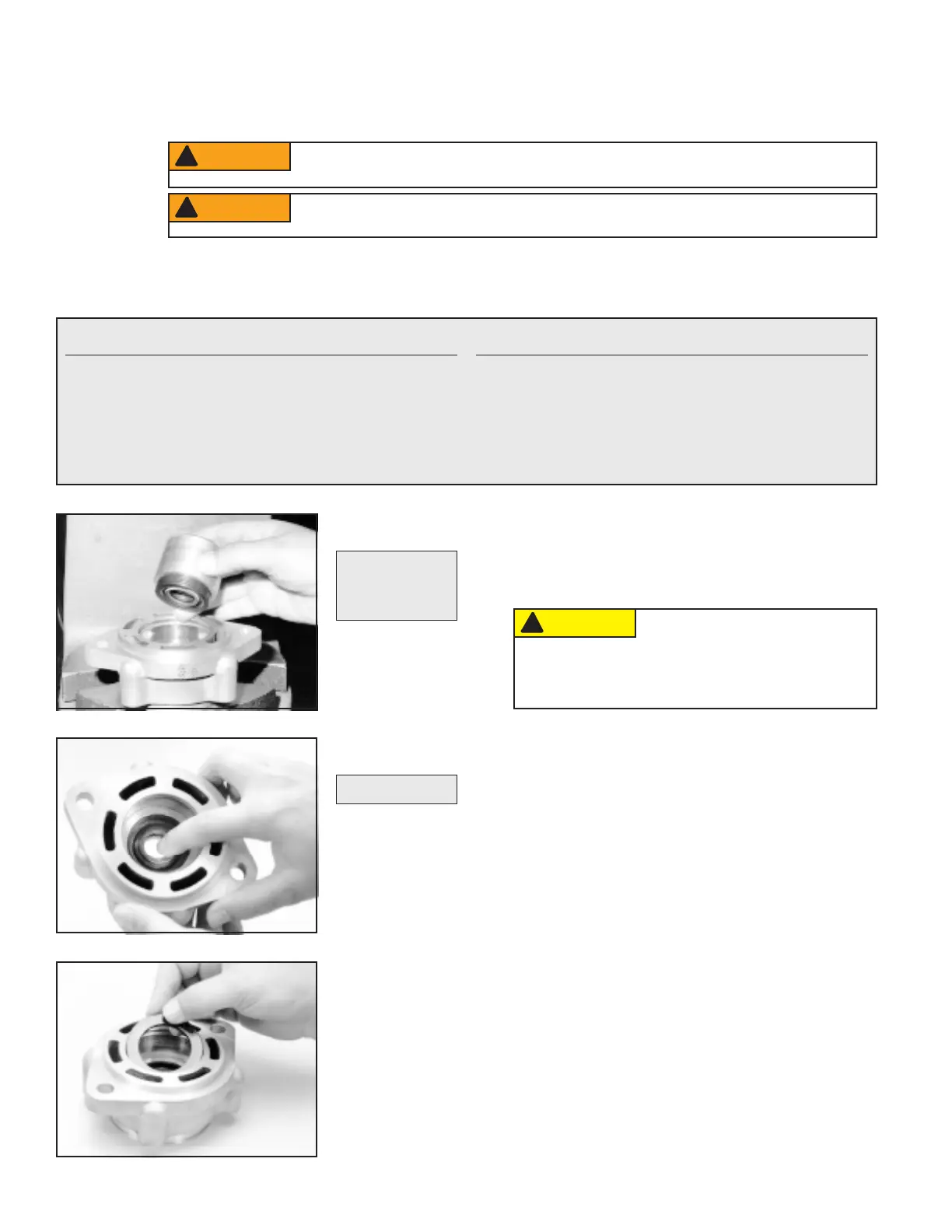

Install spacer 3. Install the spacer (24). Make sure it lays flat. There

is no up or down for the spacer.

Grease

CAUTION

!

!

WARNING

!

WARNING

Loading...

Loading...