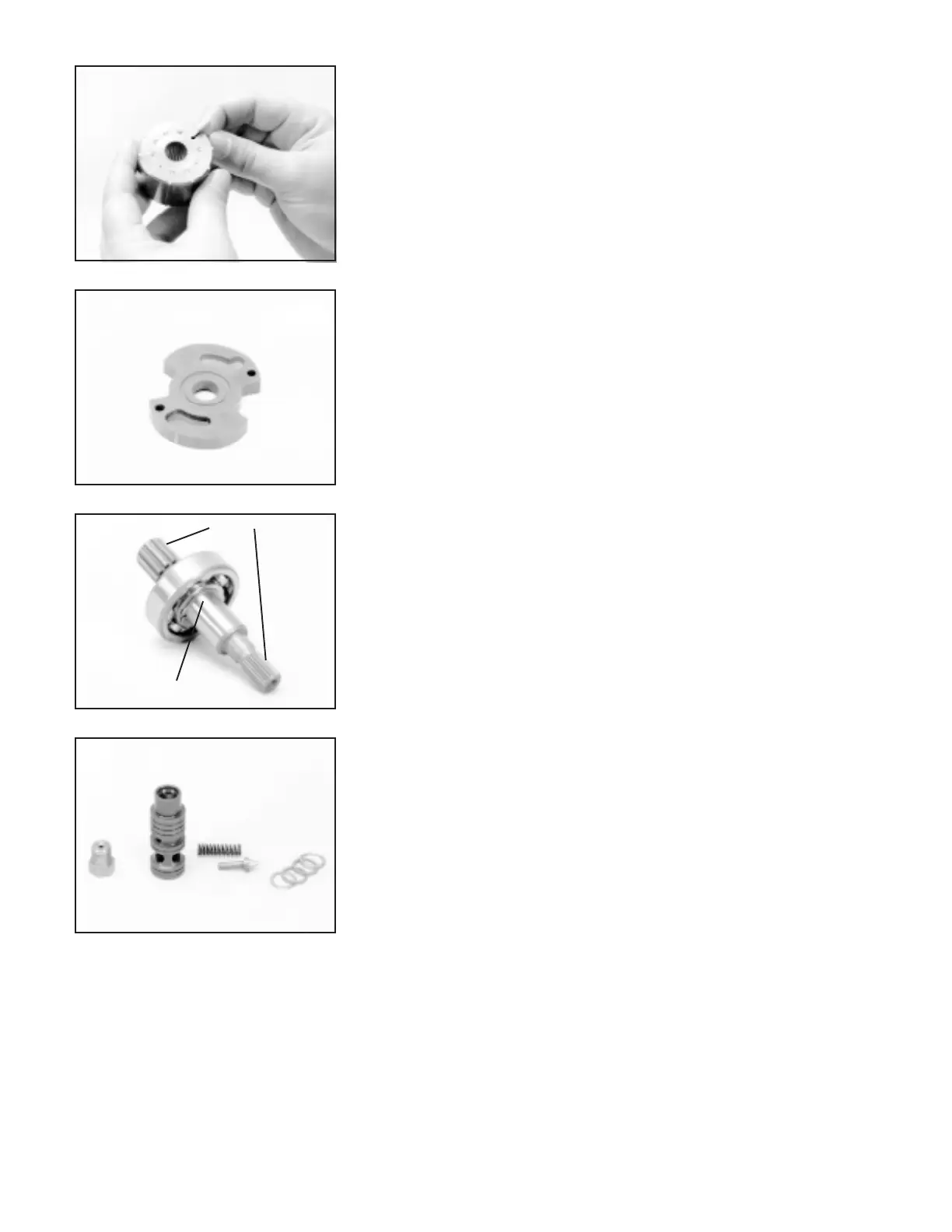

5. Inspect the rotor (16) and vanes (15) for abnormal

wear or damage. There will be normal polish marks

on both the top and bottom. The vanes need to be

free to slide both up and down and in and out. If

vanes are removed for inspection, make sure to

reinstall them with the rounded edge out.

Inspect rotor and

vanes

Inspect bottom

plate

6. Check the bottom plate (17) for abnormal wear

patterns.

7. Check the input shaft (28) for damaged splines and

unusual wear or grooves around the shaft seal area.

Grooves you can detect with your fingernail necessi-

tate replacement of the input shaft.

The ball bearing (26) should exhibit free-rolling

operation.

Inspect input shaft/

Ball Bearing

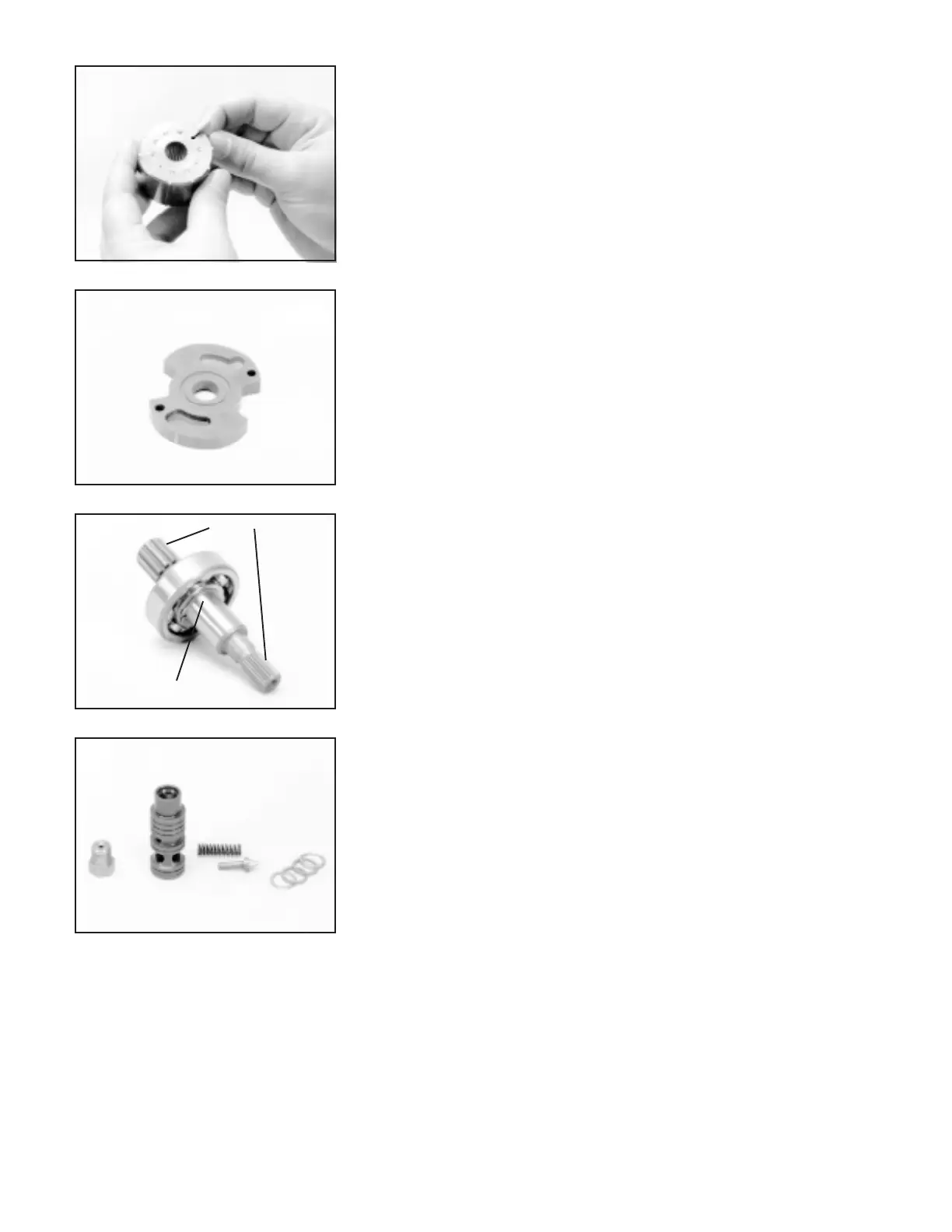

8. Inspect spool components as follows: Check all

components for damage. Check the relief valve

seat assembly (6E) for wear or chipping. Back flush

with air and solvent if necessary. Check the spool

for nicks or burrs.

Inspect spool

components

Splines

Shaft Seal Area

Loading...

Loading...