Inspection

Because they are flammable, be extremely careful when using any solvents. Even a small

explosion or fire could cause injury or death.

Wear eye protection and be sure to comply with OSHA or other maximum air pressure

requirements.

Make sure all sealing surfaces and seal cavities are free from nicks and corrosion. Any nicked or

corroded surface requires part replacement to ensure proper sealing.

Wash all parts in clean, OSHA approved solvent. Air blow them dry only.

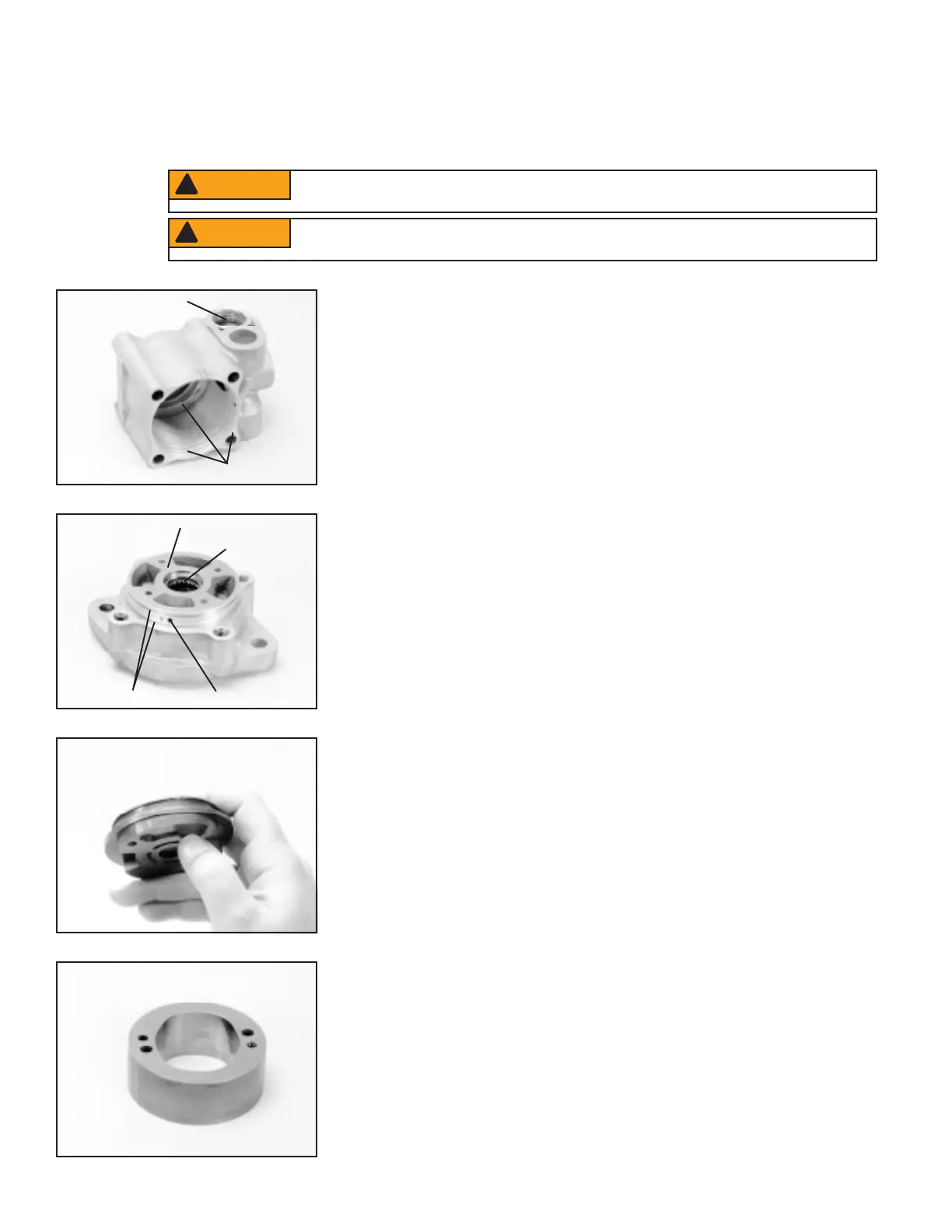

1. Inspect the housing (1) for cracks, stripped threads,

damaged valve bore and damaged sealing areas.

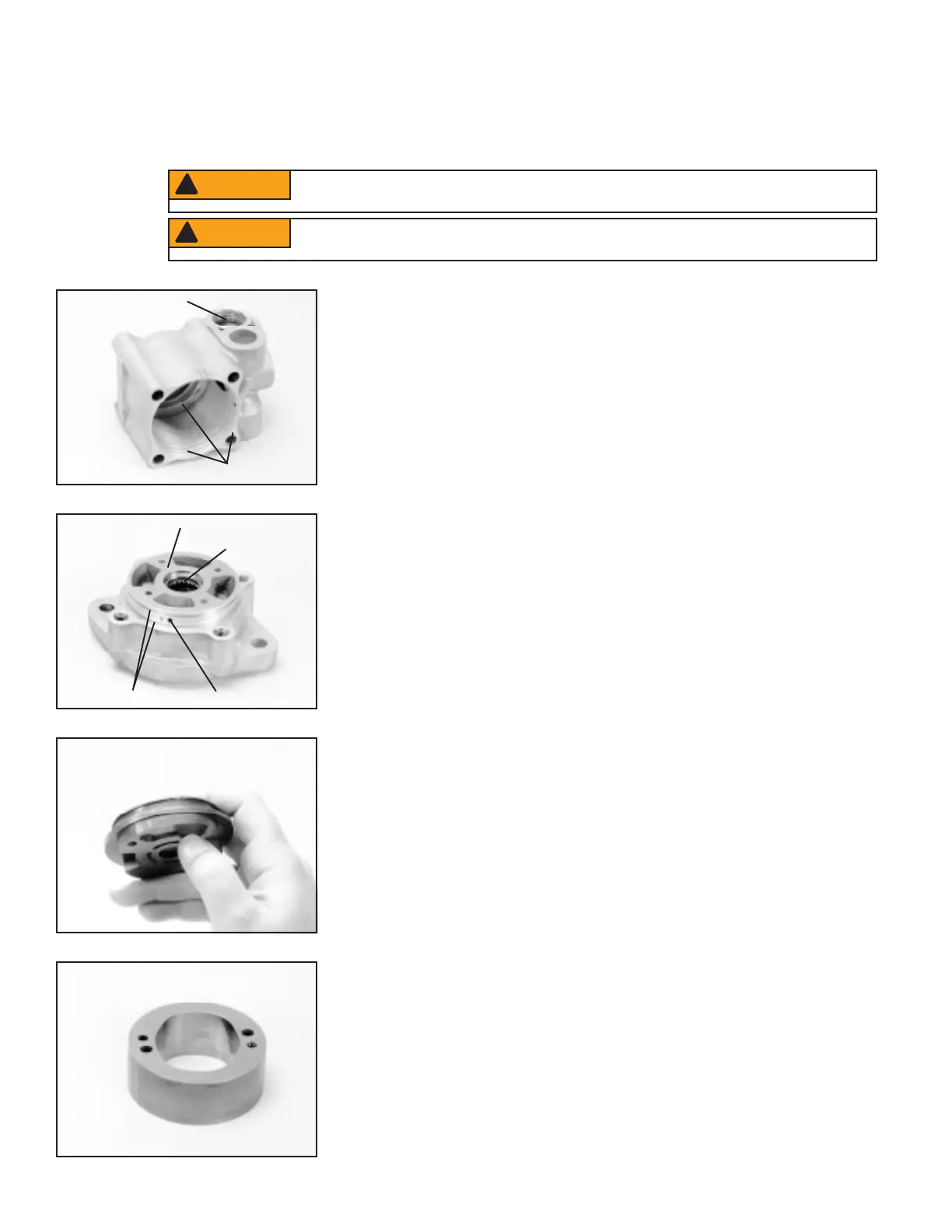

2. Inspect the cover (21) for nicks in o-ring seal

grooves. Make sure the seal drain hole is open, and

the seal bore is free of nicks and other damage.

Make sure the surface on which the bottom plate

rests is flat and free of nicks and other damage.

Make sure all needles roll freely in the needle

bearing (22).

Inspect housing

Inspect cover

3. Inspect the top plate (13) for seal area nicks, and

abnormal wear or erosion. A polished pattern from

the rotor and vanes is normal, grooves you can feel

with your fingernail are not normal.

4. Look for obvious damage on the inside of the cam

ring (14) like abnormal wear, erosion or surface

imperfections.

Inspect cam ring

Inspect top plate

!

WARNING

!

WARNING

Valve Bore

Sealing Areas

Seal Grooves

Seal Drain Hole

Bottom Plate Surface

Needle Bearing

Loading...

Loading...