Section 03: FUEL SYSTEM

PA1562

6

7. Start the engine and check for leaks.

NOTE

There is a fuel system shut-off valve on the

discharge side of the secondary fuel filter. This

check valve is designed to prevent fuel loss at

time of filter replacement.

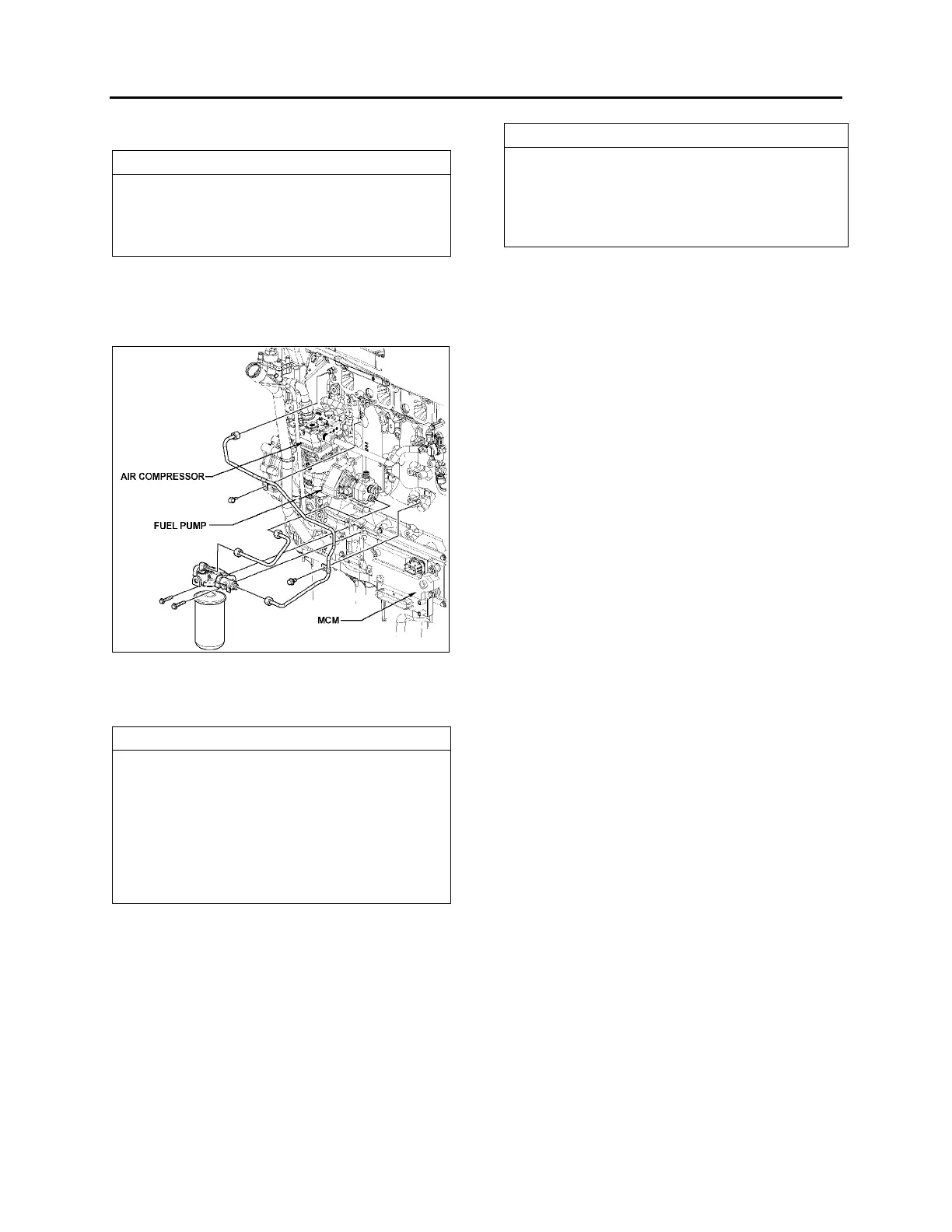

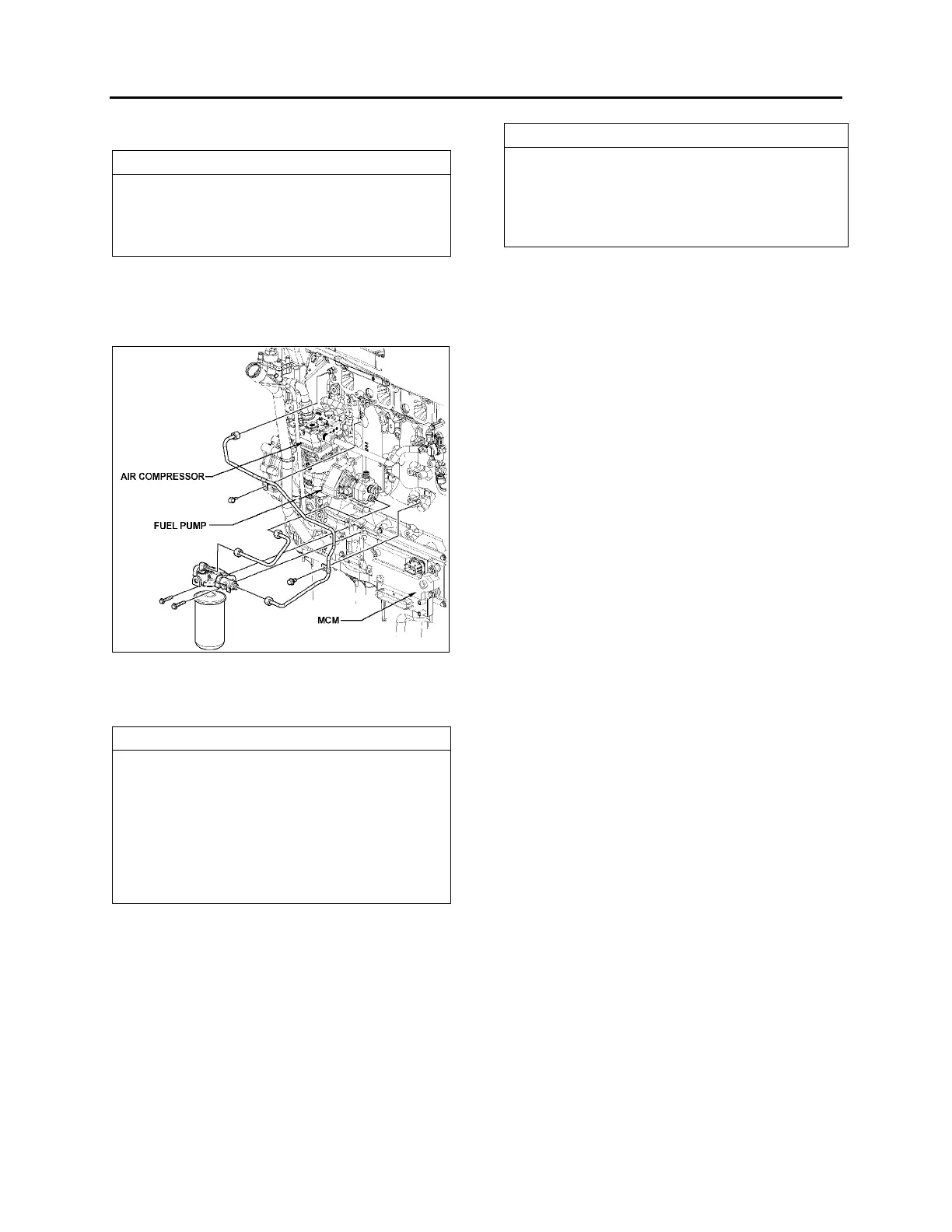

1.6 FUEL PUMP INSTALLATION

The fuel pump is driven off of the rear of the air

compressor.

FIGURE 6: FUEL PUMP LOCATION

03070

1. If removed, install inlet and outlet fittings in

the cover of the fuel pump.

NOTE

New fittings have sealant already applied.

When reusing fittings, coat the threads lightly

with Locktite Pipe Sealant, Detroit Diesel

number J 26558-92, or equivalent, before

installing. To prevent sealant from entering

fuel system, do not apply to the first two

threads of the fitting. Do not use Teflon tape

or paste on the fittings.

2. Install drive coupling in drive hub of the fuel

pump. Install a new gasket to the mounting

flange of the pump.

3. Index the drive coupling with the drive hub on

the end of the air compressor crankshaft and

align the pump mounting bolt holes with

those in the air-compressor rear cover.

NOTE

When correctly positioned, the outlet fitting on

the pump should be in approximately an 8

o'clock position when viewed from the rear,

and the drain opening in the pump body facing

down.

4. Seat the fuel pump squarely against the air

compressor. Pilot the flange on the pump

body, in the opening in the rear cover of the

compressor. Install three mounting bolts and

tighten them to 22-28 lbf-ft (30-38 Nm).

5. Connect the fuel inlet and outlet lines to the

fuel pump and tighten.

6. Prime engine fuel system before starting

engine to ensure pump seal lubrication and

prompt engine starting.

Loading...

Loading...