Section 12: BRAKE AND AIR SYSTEM

PA1562

8

Pay particular attention to the internal passages.

Inspect all parts for damage and replace if

necessary.

6. AIR GAUGES (PRIMARY, SECONDARY

AND ACCESSORY)

The air pressure gauges, located on the

dashboard (see "Operator's Manual"), are

connected to the DC-4 double check valve,

located on the pneumatic accessory panel in the

front service compartment.

The latter is connected to the air lines running

from the primary and secondary air tanks, as

shown on the pneumatic system diagram

provided in the technical publications box. The

accessory air gauge is connected to the

accessory air tank using the drain valve

connector. The vehicle should never be set in

motion until the buzzer alarm and warning lights

turn off, i.e. when air pressure registers at least

66 psi (455 kPa). Moreover, if pressure drops

below 66 psi (455 kPa), the "Low air pressure"

warning lights will turn on, and the "Low air

pressure" buzzer will sound. Stop the vehicle

immediately, determine and correct the cause(s)

of pressure loss. Check the gauges regularly

with an accurate test gauge. Replace the gauge

with a new unit if there is a difference of 4 psi

(27 kPa) or more in the reading.

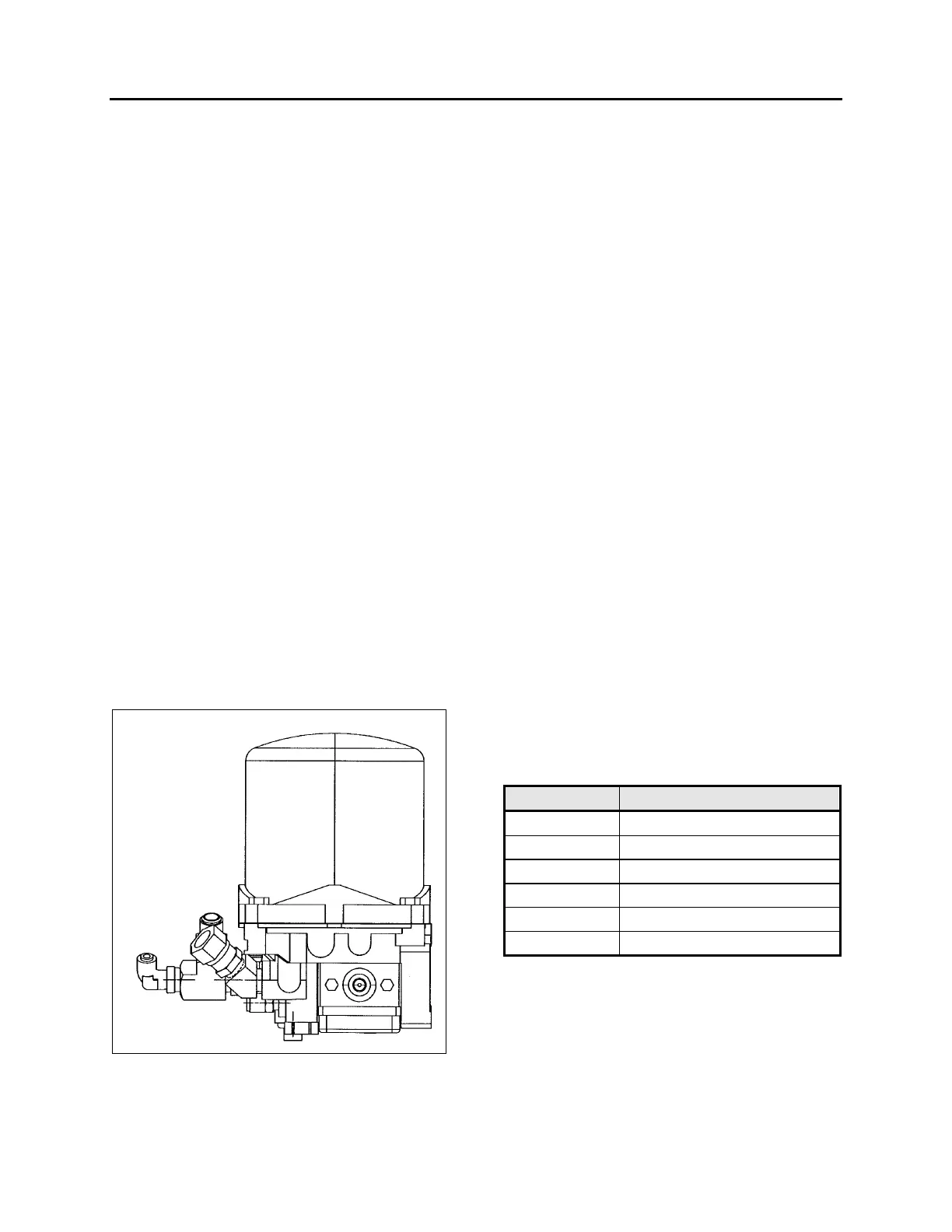

7. AIR FILTER/DRYER

FIGURE 6: HALDEX AIR FILTER DRYER

12194

The air filter/dryer is located in front of rear

wheelhousing above drive axle (Fig. 1, 2 & 6).

Its purpose is to remove moisture that could

damage the air system before the air enters the

system reservoir. The air filter/dryer also filters

the air to remove dirt, compressor oil, and other

contaminants that can damage the system.

Change cartridge every 100,000 miles (160 000

km) or once every two years, whichever comes

first. The air dryer may be purged for mainte-

nance purposes using the remote drain valve

located in the engine compartment and

accessible through the engine compartment

R.H. side door. The valve is positioned close to

the L.H. side of door opening (Fig. 3). The air

filter/dryer has a built-in governor to maintain the

system between 108 psig and 123 psig.

Maintenance and repair information is supplied

in the maintenance information annexed to this

section.

7.1 AIR FILTER/DRYER PURGE TANK

A tank is supplied to purge the air filter/dryer to

remove moisture and contaminants.

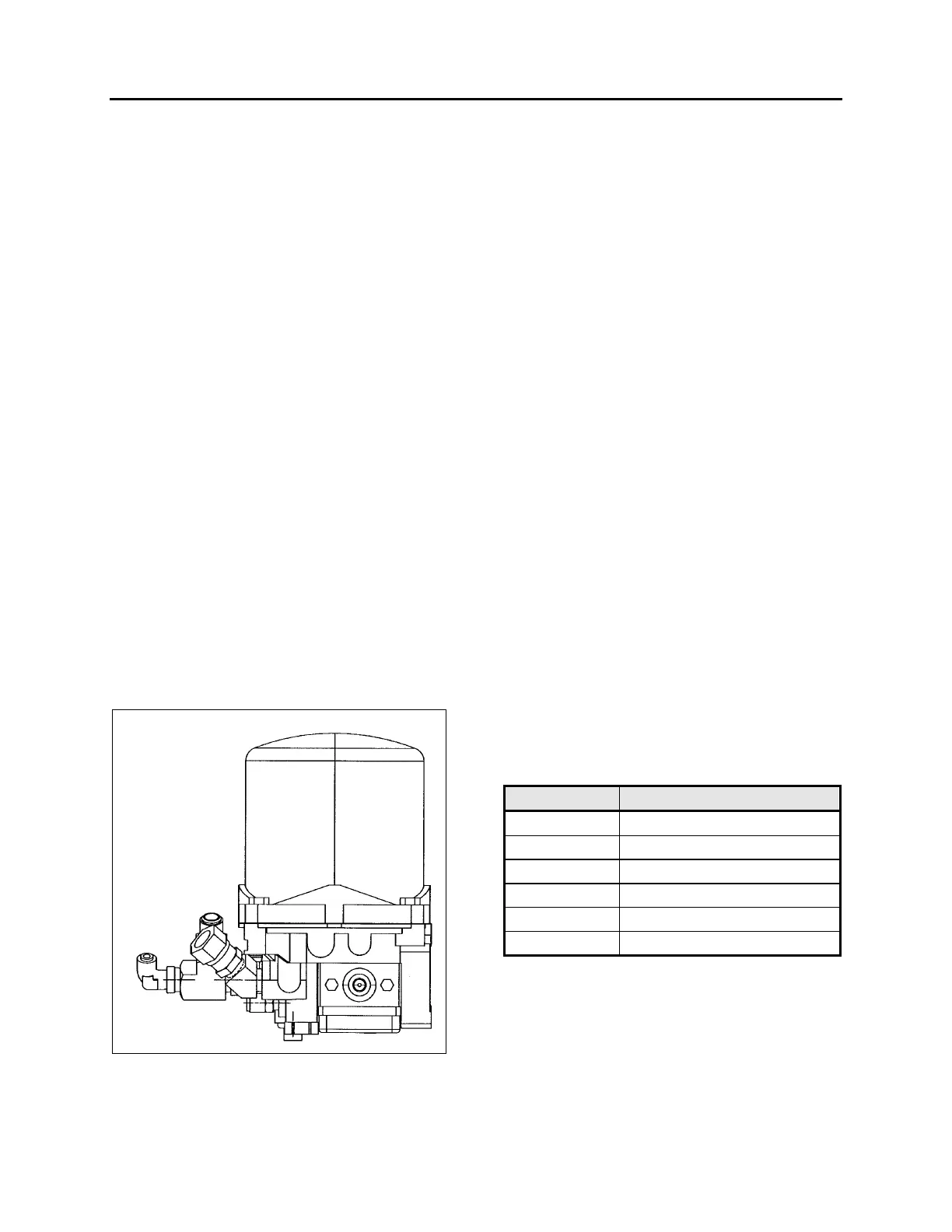

8. AIR LINES

Copper piping, nylon-reinforced tubing, and

flexible hoses are used to connect the units in

the pneumatic system, including air brake

system, suspension system and accessory

systems such as the entrance door, fresh air

damper cylinder, air horns, etc. Furthermore, the

nylon tubing is color coded to ease identification.

Refer to the following table for the complete

color identification code. Service instructions for

each type of air line are also provided under the

applicable headings.

Color Circuit

Red Secondary

Green Primary and Delivery

Yellow Parking Brake

Blue Suspension

Black Accessory

Brown Trailer Brake

8.1 COPPER PIPING

A heat dissipation copper piping assembly is

used to dissipate the heat coming from the

compressor before it enters the air filter/dryer.

Connections should be checked for leakage at

least every 6,250 miles (10 000 km) or twice a

year, whichever comes first. Tighten or replace

when necessary. When replacing copper piping,

Loading...

Loading...