6

37

Avoid abuse

6-1

Abuse can shorten the life of a wheel. Lack of care in changing a tire, heavy pounding of the

wheel rim, overloading, exposure to excessive heat or hitting curbs at high speed or a sharp angle

can damage wheels.

Do not overinflate. Use the tire manufacturer's recommended pressure, but under no cir-

cumstances exceed cold inflation pressures listed in Section 2 Specifications of this manual.

Before mounting the tire perform a wheel fitment check to insure proper clearance from any

obstructions.

Refer to tire manufacturer’s recommendation for proper tire pressure. Before mounting the tire

perform a wheel fitment check to insure proper clearance from any obstructions.

Wheel cap nuts must be kept tight (see Section 5-8). When checking the cap nuts on dual disc

wheels utilizing the stud located ball seat mounting system, loosen every other outer cap nut and

then check the torque of the inner cap nuts. Retorque the loosened outer cap nuts. Repeat proce-

dure with the rest of the nuts. Check all cap nuts for proper torque after the first use or any removal.

Inspect wheels and check wheel nuts during service stops (see Section 3). Dirt streaks from cap nuts

may indicate looseness.

Flange nuts must be kept tight, and studs and nuts should be checked frequently. At tire changes

nuts and studs should be inspected to be sure they are in good condition. If nuts require frequent

tightening or studs break frequently, hardware and mounting practices should be reviewed.

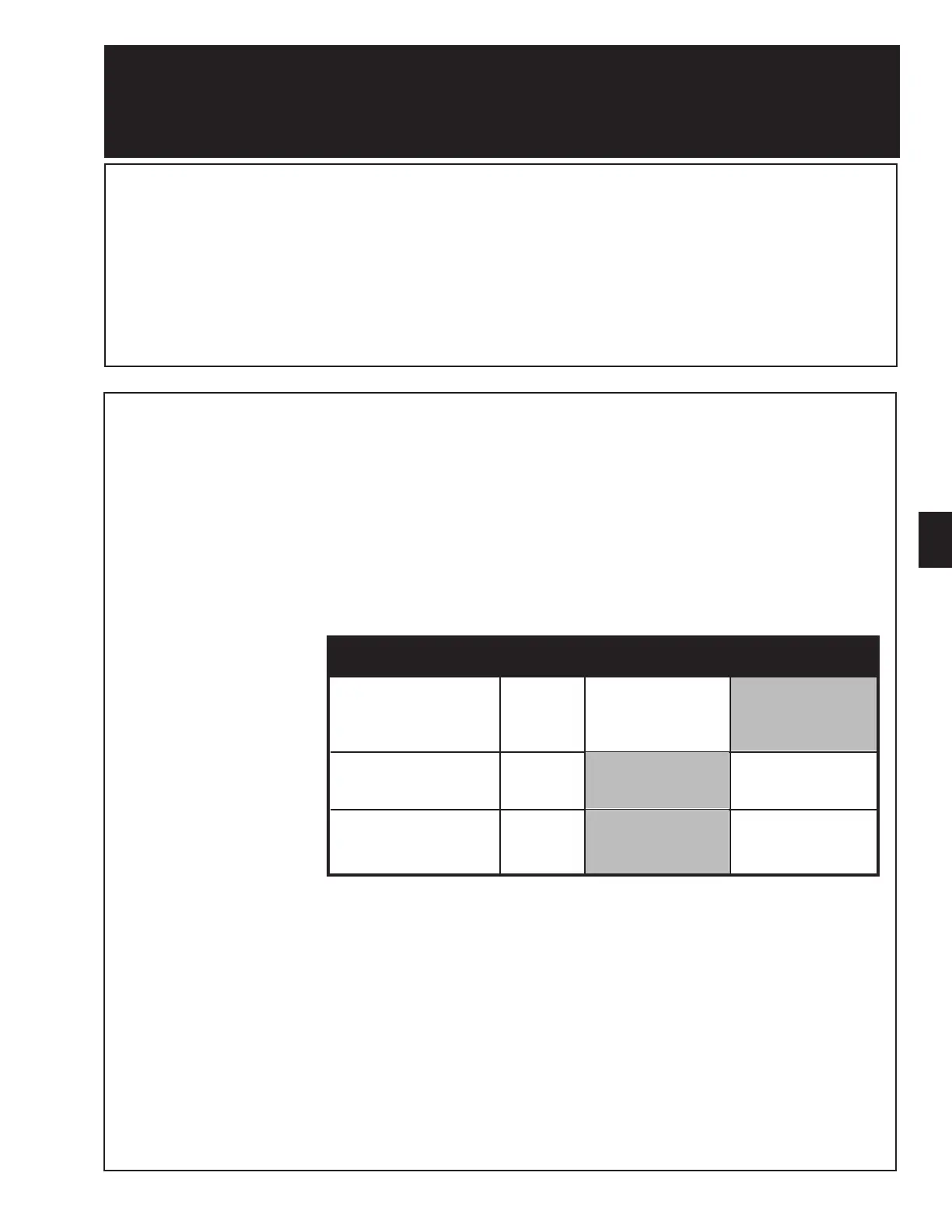

For proper nut torque, refer to the chart below:

Mount Nut Torque Level Ft-Lb Torque Level Ft-Lb

Type Thread Lubricated* Dry*

Hub piloted using

11/16" - 16 300-400

two-piece flange nut

7/8 - 14 350-400

M20 x 1.5 280-330

M22 x 1.5 450-500

Stud piloted, double cap

3/4" - 16 450-500

nut standard type

1-1/8" - 16 450-500

(7/8” radius)

Stud piloted, double cap 15/16" - 12 750-900

nut heavy duty type 1-1/8" - 16 750-900

(1-3/16” radius) 1-5/16" - 12 750-900

*For nuts used on hub piloted wheels, apply two drops of oil to the point between the nut and

flange and two drops to the first two or three threads at the tip of each stud (see Section 5-10).

For nuts used on stud piloted wheels, apply two drops of oil to the first two or three threads at the

tip of each stud only (see Sections 5-8).

NOTE:

1. If using specialty fasteners (cap nuts), consult the manufacturer for recommended torque values.

2. Tightening wheel nuts to their specified torque is extremely important. Undertightening

which results in loose wheels can damage wheels, studs and hubs, and can result in wheel loss.

Overtightening can damage studs, nuts and wheels and results in loose wheels as well.

3. All torque wrenches, air wrenches and any other tools should be calibrated periodically to ensure

the proper torque is applied.

Keep wheel nuts

tight

6-2

Proper Torque, Wheel Identification

6

and Valves

Loading...

Loading...