Section 06: ELECTRICAL

PA1562

40

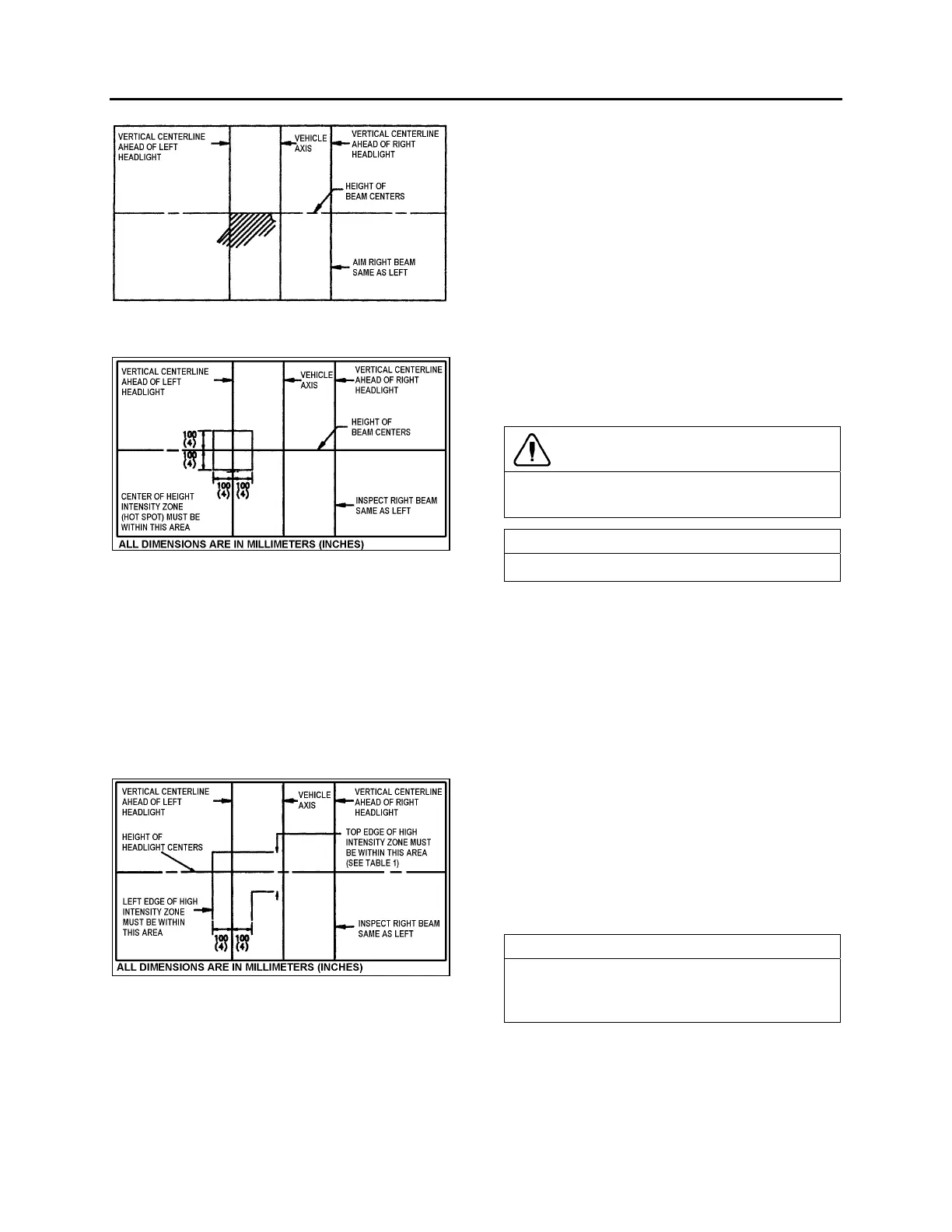

FIGURE 28: HIGH-INTENSITY ZONE (SHADED AREA) OF

A PROPERLY AIMED LOWER BEAM ON THE AIMING

SCREEN 7.6 M (25FT) IN FRONT OF VEHICLE

06504

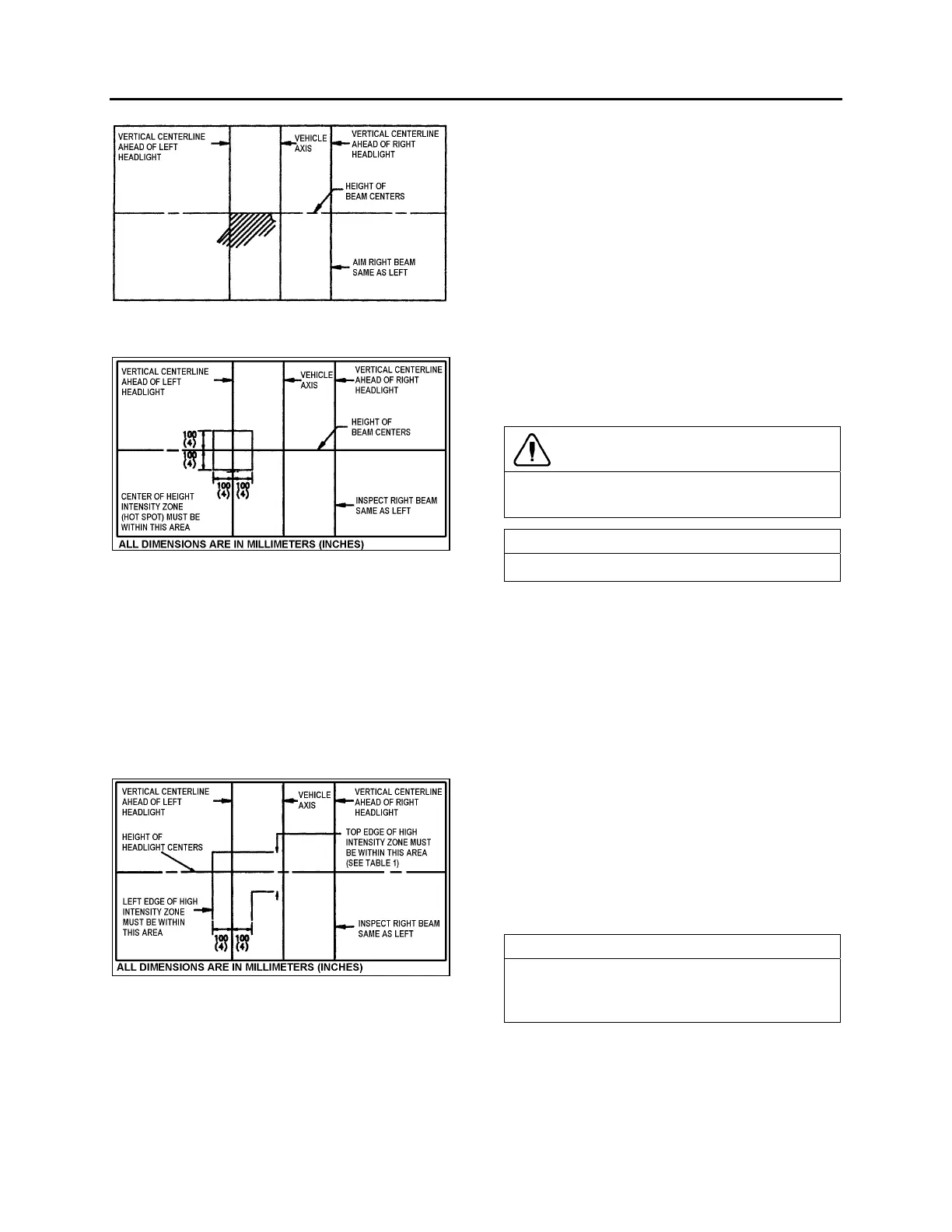

FIGURE 29: AIM INSPECTION LIMITS FOR UPPER-BEAM

HEADLIGHTS

06505

7. The inspection limits in the vertical direction

for low-beam headlights or the low beam of

a dual-beam headlight, shall be as

described in Table 1. In the horizontal

direction, the left edge of the high-intensity

zone shall be located from 10 cm (4 in) left

to 10 cm (4 in) right of the vertical centerline

of the beam. The viewing screen shall be

located 7.6 m (25 ft) in front of the vehicle

(Fig. 30).

FIGURE 30: AIM INSPECTION LIMITS FOR LOWER-

BEAM HEADLIGHTS

06506

9.1.4 Sealed-Beam Unit

Bulb Removal and Replacement

1. Pull the release handle located inside the

front service compartment to tilt down the

entire bumper assembly.

2. Remove the headlight screw fixing the

headlight assembly, then tilt headlight

assembly down (Fig. 24 and 25).

3. Remove connector from headlight bulb.

4. Remove the bulb by pushing and rotating it

out of the socket.

5. Install the new bulb by reversing the

previous procedure.

CAUTION

During this step, avoid contacting the bulb

with the fingers not to alter the bulb life.

NOTE

Do not disrupt headlight adjustment screws.

Module Replacement

1. Pull the release handle located inside the

front service compartment to tilt down the

entire bumper assembly.

2. Remove the headlight screw fixing the

headlight assembly, then tilt headlight

assembly down (Fig. 24 and 25).

3. Remove connector from headlight bulb.

4. Unfasten three metal clips attaching

headlight unit to support.

5. Install new module and fasten metal clips.

6. Install wiring connector on back of new

sealed beam unit.

7. Tilt headlight assembly up into its housing

then secure using fixing screw.

NOTE

Make sure headlight assembly is properly

positioned into its housing before securing

using fixing screw.

8. Perform alignment procedure.

Loading...

Loading...