Section 11: REAR AXLES

PA1562

4

1.4.3 Speed Sensors (Anti-Lock Brake

system, ABS)

For removing and installing the drive axle speed

sensors (for anti-lock brake systems, ABS), refer

to Section 12: ‘’Brake and Air System’’ and to

Rockwell WABCO Maintenance Manual: “Anti-

Lock Brake Systems For Trucks, Tractors and

Buses", annexed at the end of section 12.

1.5 REMOVAL AND REINSTALLATION

The following procedure deals with the removal

of the drive axle assembly and its attachments

as a unit. The method used to support the axle

during removal and disassembly depends upon

local conditions and available equipment.

1. Raise vehicle by its jacking points on the

body (fig. 5 or see Section 18, "Body" under

heading "Vehicle Jacking Points"). Place jack

stands under frame. Remove drive axle

wheels (if required, refer to Section 13,

"Wheels, Hubs And Tires".

FIGURE 5: JACKING POINTS ON FRAME 18618

2. Exhaust compressed air from the air supply

system by opening the drain cock on each

air reservoir.

3. Disconnect the propeller shaft as directed in

Section 9, "Propeller Shaft", in this manual.

4. On both sides of the vehicle, unscrew

fasteners retaining front wheel housing plastic

guards, and remove them from vehicle.

5. Disconnect both height control valve links

from air spring mounting plate brackets then

move the arm down to exhaust air

suspension.

6. Remove cable ties securing the ABS cables

(if vehicle is so equipped) to service brake

chamber hoses. Disconnect the ABS cable

plugs from the drive axle wheel hubs.

NOTE

When removing drive axle, if unfastening cable

ties is necessary for ease of operation,

remember to replace them afterwards.

7. Disconnect the brake chamber hoses.

NOTE

Position the hoses so they will not be damaged

when removing the axle.

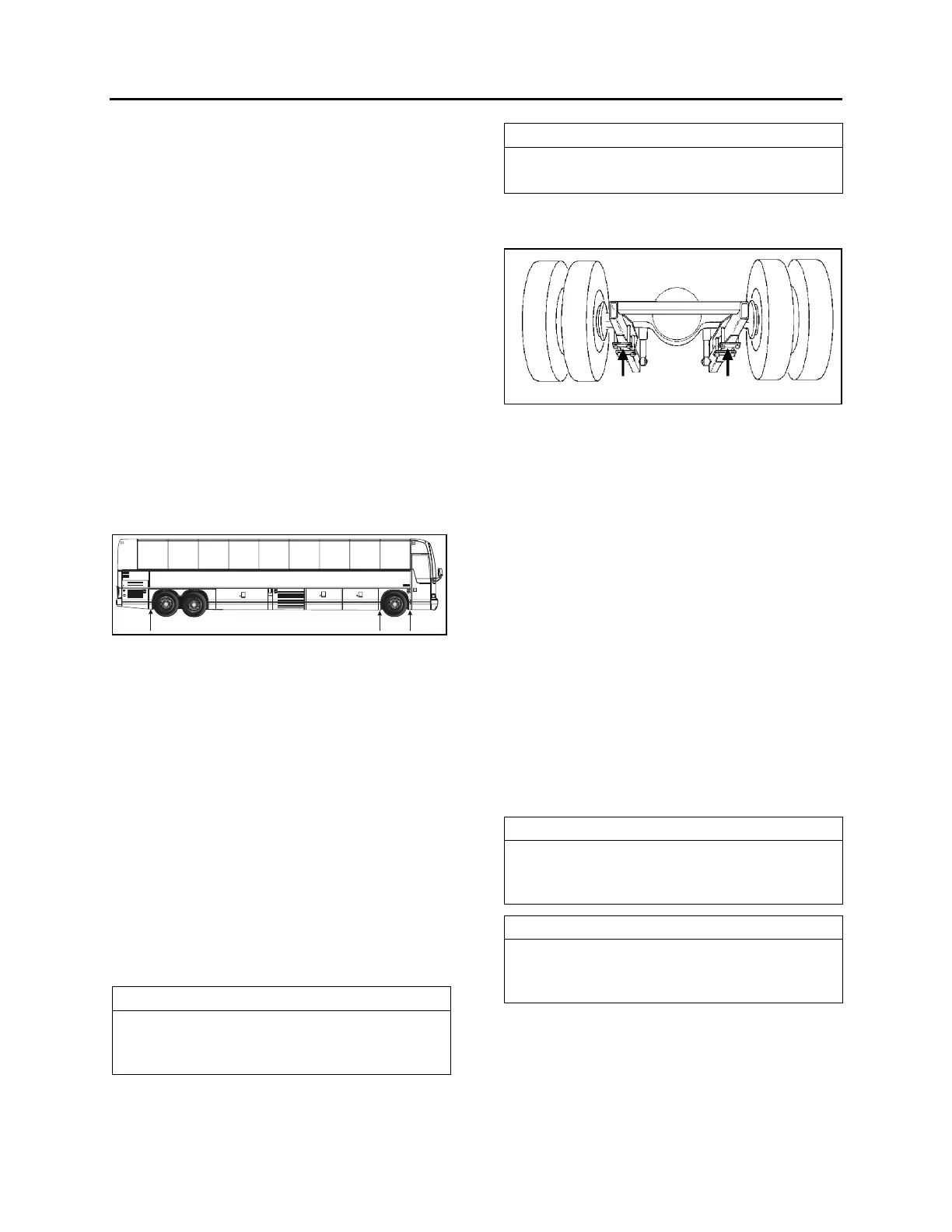

8. Install jacks under the axle jacking points to

support the axle weight (refer to figure 6).

FIGURE 6: JACKING POINTS ON DRIVE AXLE 11005

9. Remove the four shock absorbers as

outlined in Section 16, "Suspension" under

heading "Shock Absorber Removal".

10. Remove the sway bar.

11. Remove the lower and upper longitudinal

radius rod supports from vehicle sub-frame

as outlined in Section 16, "Suspension",

under heading "Radius Rod Removal".

12. Remove the transversal radius rod support

from the vehicle sub-frame.

13. Remove the two retaining nuts from each of

the four air bellows lower mounting

supports.

14. Use the jacks to lower axle. Carefully pull

away the jacks axle assembly from

underneath vehicle.

15. Reverse removal procedure to reinstall drive

axle.

NOTE

Refer to Section 16, “Suspension” for

suspension components' proper tightening

torques.

NOTE

Refer to section 13 "Wheels, Hubs And Tires"

for correct wheel bearing adjustment

procedure.

1.6 DISASSEMBLY AND REASSEMBLY

Disassembly and re-assembly procedures are

covered under applicable headings in Meritor's

"MAINTENANCE MANUAL, NO. 5", annexed to

this section.

Loading...

Loading...