9

3

Dimension checks

(continued)

Tire wear or ride problems

If you experience tire wear or ride problems it may be helpful to check radial run out. Remove

the wheel from the vehicle, deflate and remove the tire (see Section 4-5, for recommendations and

instructions for demounting tubeless tires).

Remount the wheel on the vehicle without the tire. Be sure to follow proper mounting procedures to

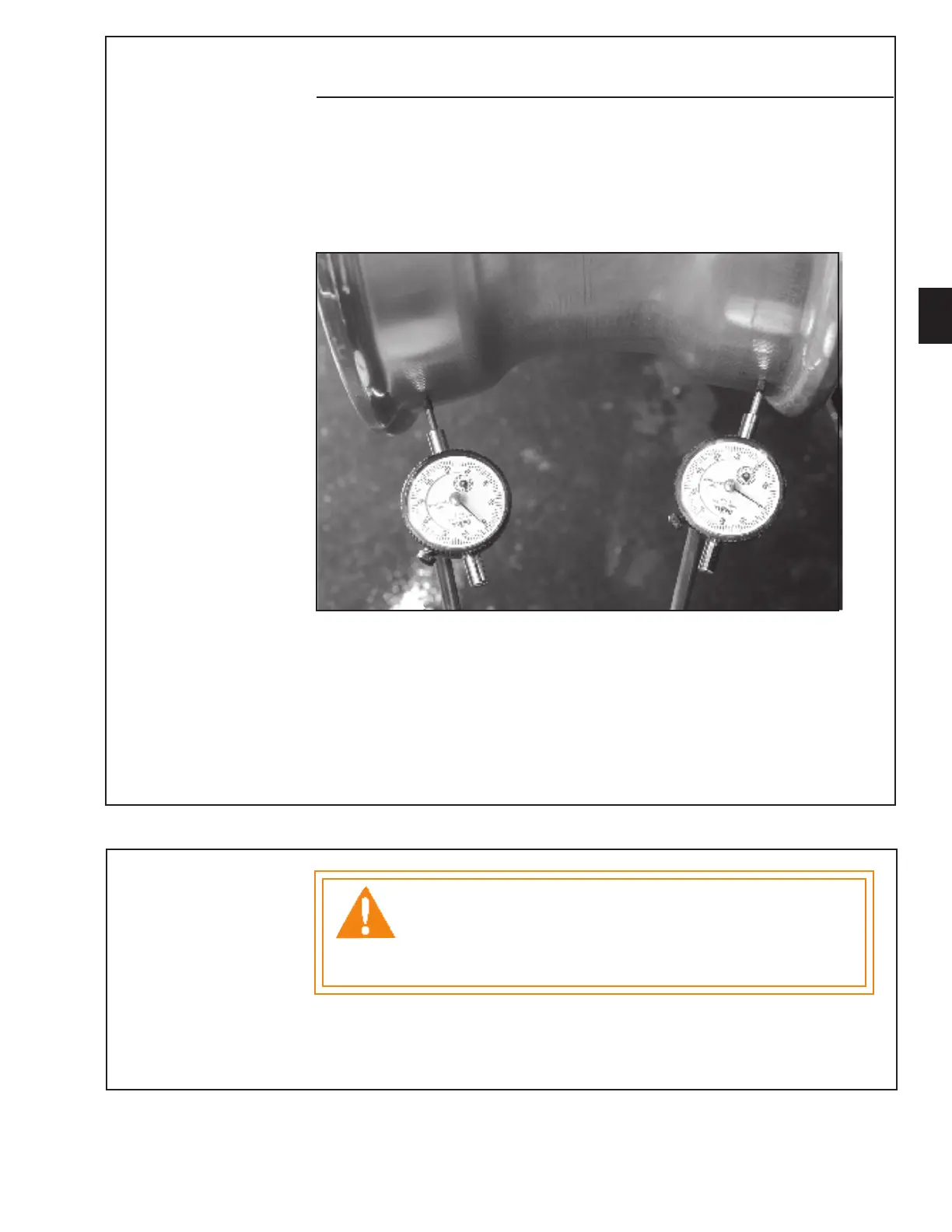

assure the wheel is well centered on the hub. Place a dial indicator as illustrated below to trace the bead

seats of the wheel. Rotate the wheel noting the amount of variation shown on the dial indicator. Note:

Alcoa aluminum wheels should be tested for radial run out only at the bead seat surface. A total indi-

cator reading of .040 inches or less is acceptable.

Tire wear can also be caused by improperly seated tires. Inspect the tire for proper seating on the wheel.

The tire beads may not be seated properly. If so, remove the wheel from the vehicle, deflate and break

the bead seats (see Section4-5 for recommendations and instructions for demounting tubeless tires).

Adequately lubricate the bead seats and properly reseat the tire beads. Reinflate the wheel in a safety

cage or other suitable restraint (refer to OSHA rule 1910.177, paragraph b, see Section 7).

Cracked or

damaged wheel

checks

3-5

WARNING

Cracked or damaged wheels may fail or come off the vehicle.

Wheels that fail or come off the vehicle while it is moving can cause serious injury or

death.

Immediately and permanently remove cracked or damaged wheels from service.

Visually inspect wheels for cracks or damage. Remove wheels from service with known or suspected

damage.

WARNING

Loading...

Loading...