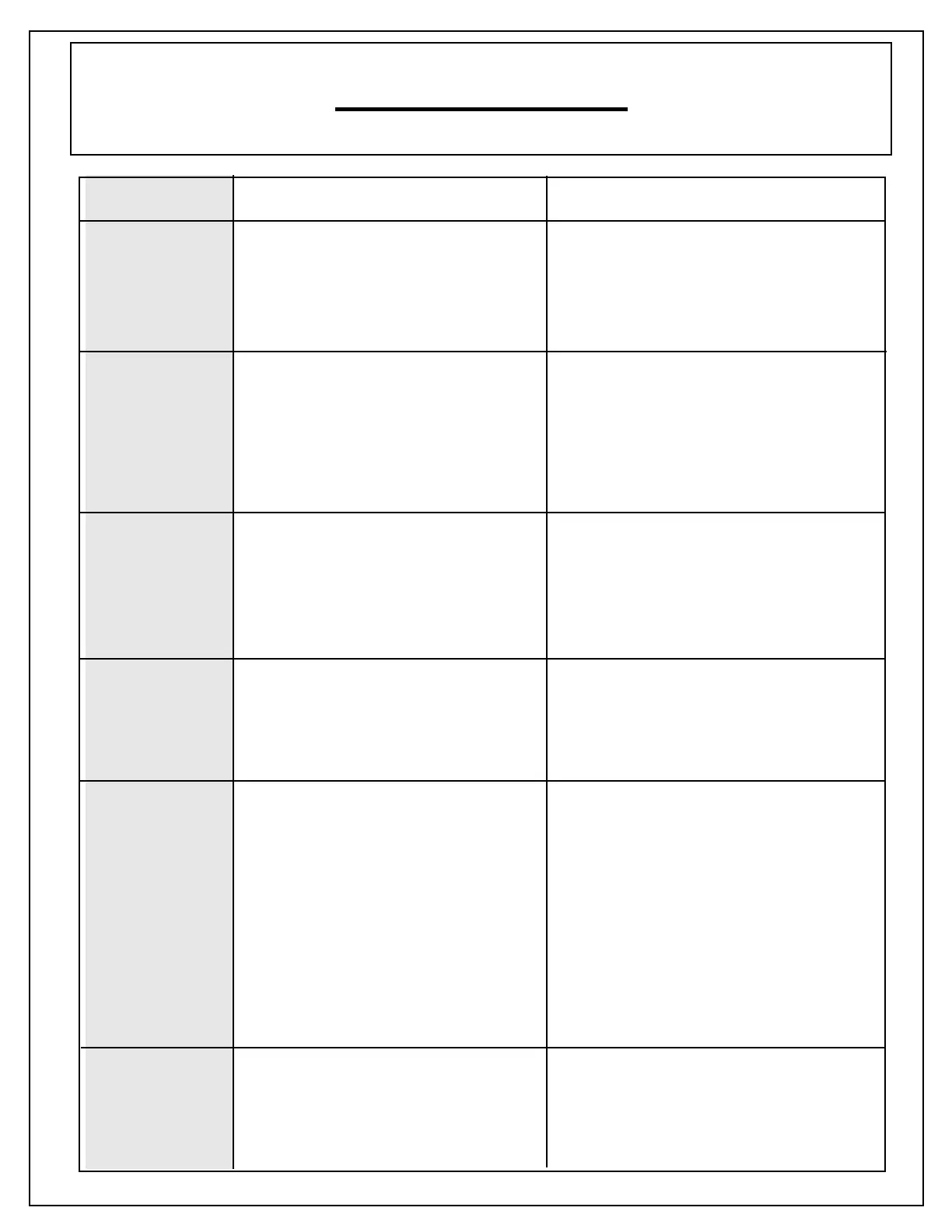

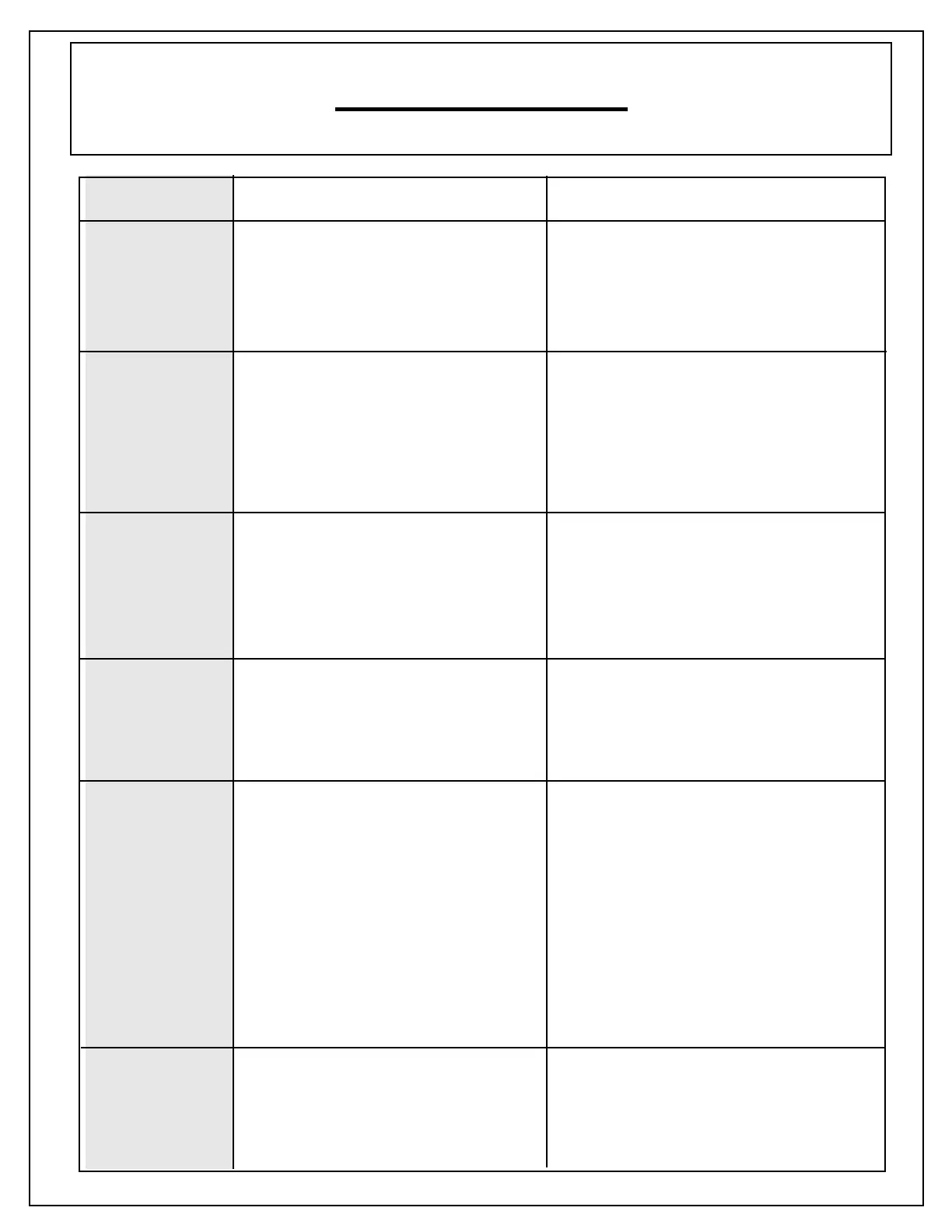

T

roubleshooting

Problem Cause Repair

Water in air 1. Contaminants in desiccant. 1. Change desiccant cartridge. Check

system compressor for excessive oil passage.

2. Leaks in air system. 2. Tighten air connections, soap

connection and recheck for leaks per

Testing the DRY

est

section.

Constant 1. Defective dryer outlet check valve. 1. Clean valve seat and replace

exhaust of air check valve.

at air dryer 2. Dryer unloading valve not closing. 2. At compressor cut-out there must be a

and not slight blow of regenerated air from the

Blow-Thru Type purge tank for approximately 30

seconds. If air flow continues, replace

valve pack.

Excessive 1. Excessive leaks in air system. 1. Tighten air connections, soap

compressor connection and recheck for leaks.

cycling 2. Defective dryer outlet check valve. 2. Clean valve seat and replace

check valve.

3. Undersize compressor, duty cycle of 3. Reduce air demand or use greater

compressor should not exceed 25%. output compressor.

Safety valve 1. Desiccant cartridge is plugged. 1. Excessive oil passage from compressor.

is open Check for worn compressor. Replace

desiccant cartridge.

2. Ice block in dryer. 2. Check heater function.

3. Excessive system pressure. 3. Repair or replace governor.

Short life of 1. Air at inlet of dryer exceeds 170°F. 1. Extend length of compressor discharge

dryer or line; see Installing the DRY

est

section.

desiccant The 170°F dryer inlet temperature can

cartridge usually be accomplished with 12’ to 15’

of compressor discharge line.

2. Duty cycle of compressor does not 2. During normal operation the compressor

allow for sufficient time for must remain unloaded for a minimum

desiccant regeneration. of 30 seconds to allow for sufficient

purge. Lengthy loading times must be

avoided. Air dryer must be “by-passed”

in applications with high air use such as

bulk unloading.

Poor drying 1. Air at inlet of dryer exceeds 170°F. 1. Extend length of compressor discharge

efficiency line; see Installing the DRY

est

section.

The 170°F dryer inlet temperature can

usually be accomplished with 12’ to 15’

of compressor discharge line.

Loading...

Loading...