Wheel cap nuts must be kept tight (see section 4 of the Alcoa Wheel Service

Manual, July 2002). When checking the cap nuts on dual disc wheels using the

stud located ball seat mounting system, loosen every other outer cap nut and

then check the torque of the inner cap nuts. Re-torque the loosened outer cap

nuts. Repeat these steps on the remaining studs. Check all cap nuts for proper

torque after the first use or any removal. Inspect wheels and check wheel nuts

during service stops (see section 2 of the Alcoa Wheel Service Manual, July

2002). Dirt streaks from cap nuts may indicate looseness.

Flange nuts must be kept tight, and studs and nuts should be checked frequently.

At tire changes, nuts and studs should be inspected to be sure they are in good

condition. If nuts require frequent tightening or studs break frequently, hardware

and mounting practices should be reviewed.

The proper torque for ball seat cap nuts is between 350 and 400 foot-pounds for

stud threads lubricated with SAE 30W oil and between 450 and 500 foot-pounds

for threads that are not lubricated. The proper torque for M22-1.5 two-piece

flange nuts (33 mm hex head) is between 450 and 500 foot-pounds.

Keep wheel nuts

tight

Lead balance weights for Alcoa wheels are available from your Alcoa wheel

distributor. With radial tires, it may be necessary to temporarily reduce the tire

pressure to allow clearance of the weight clamp over the rim flange.

Lead balance

weights (clip-on)

Do not heat wheels in an attempt to soften them for straightening to repair damage

from striking curbs or other causes. The special alloy used in these wheels is

heat-treated, and uncontrolled heating will weaken the wheel.

Do not rework, weld, heat or braze Alcoa aluminum wheels for any reason. This

does not include normal wheel maintenance as described and approved by

Alcoa.

Do not straighten

wheels

Some fleets wish to specially identify wheels with OWNERSHIP and IN-SERVICE

DATE information. If this practice is adopted:

1. Use “Lo-Stress” stamps or equivalent.

2. Location of stamped areas on outside disc should be in space outward from a

line between hand hole centers and a minimum of one inch from the periphery of

any hand hole.

3. Location of stamped identification on inside of wheel should be as close to the

factory identification stamping as possible.

Note: Use of an impression stamp on Dura-Bright® wheels can affect the appearance

and performance of the Dura-Bright® surface treatment local to the stamp.

Owner/in-service

identification

Irregular wear on the sruface of the rim flange is caused by the chafer and side wall

area of the tire working on the surface of the rim flange. Remove the wheel from

service when rim flange wear is excessive. Excessive wear can be determined

using an Alcoa approved wear gauge and procedures. For availability, contact

Alcoa Wheel Products at 800-242-9898 or 1600 Harvard Avenue, Cleveland,

Ohio 44105. If rim flange wear becomes sharp and/or cuts the tire, contact Alcoa

Wheel Products for recommended maintenance procedures.

Rim flange wear

Alcoa drop center wheels for tubeless tires come from the factory with air valves

installed. If it becomes necessary to replace an air valve, install it using the following

torque values.

Valves

10 to 14 foot-pounds

for part numbers

7 to 11 foot-pounds

for part numbers

TR 509

TR 510

TR 511

TR 542 Series

TR 543 Series

TR 544 Series

TR 545 Series

Replacement valves may be obtained from your authorized Alcoa wheel distributor.

Always use silicone O-rings - not rubber - when reinstalling valve stems. Metal

valve stem caps are recommended over plastic.

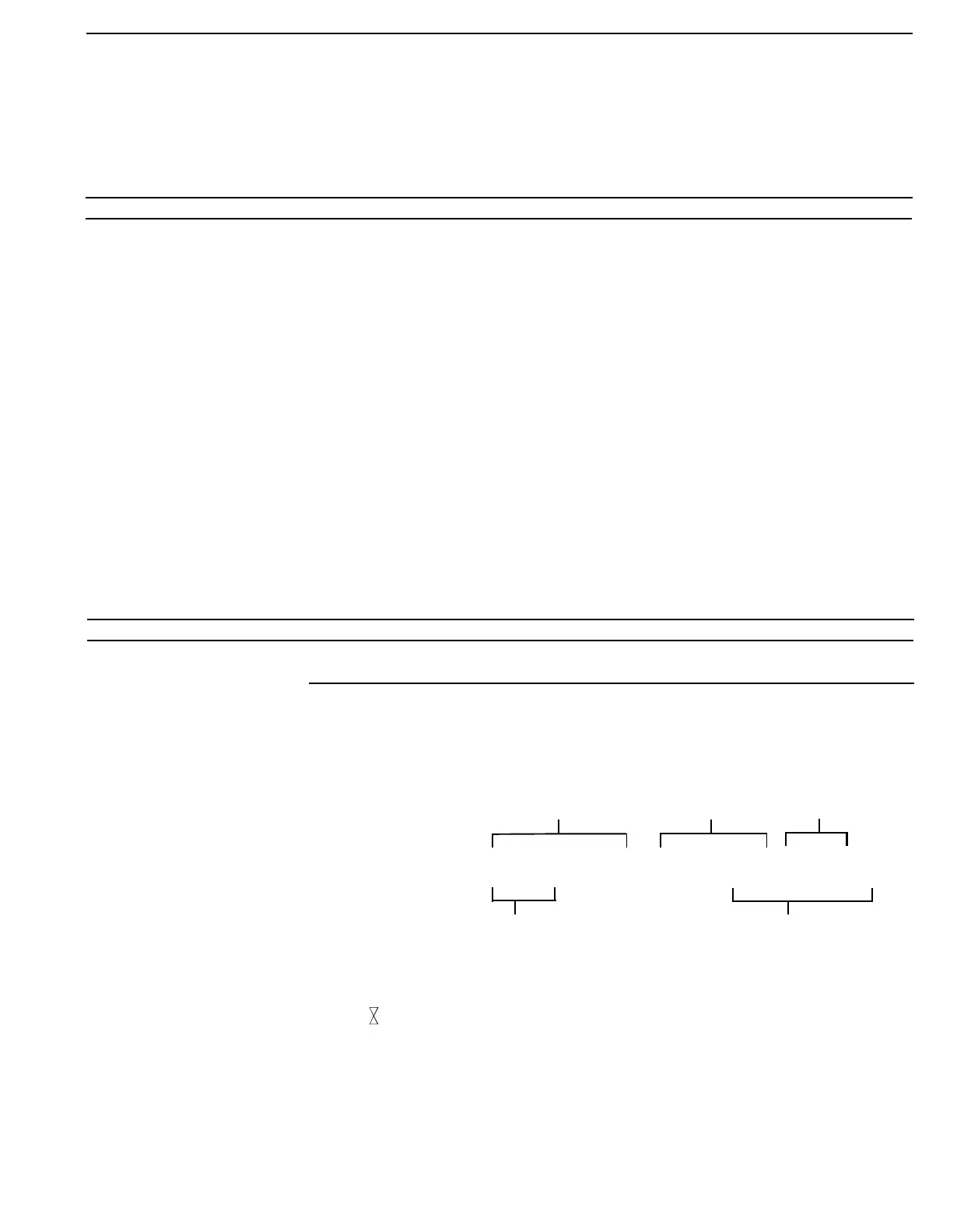

Alcoa wheel identification

Since 1977, all Alcoa aluminum disc wheels have been identified with a stamp

that shows the wheel load rating, maximum inflation pressure, date of manufacture,

part number, wheel description and DOT marking designation (shown below).

Identification

ALCOA® FORGED MAX LOAD 7300 MAX PSI 120 T-DOT

060602 PART NO 883620DB 22.5X8.25 15

O

DC

Wheel Load Rating

(Pounds)

Maximum

Inflation Pressure

FMVSS 120

Designation

Date of Manufacture

(Day/Month/Year)

Wheel Description

Prior to June 1996, all Alcoa heavy duty truck wheels has the Alcoa identification

symbol on the outside of the disc near the hand hole and in line with the valve

location. This marking was phased out on heavy duty truck wheels manufactured

after June 1996.

Note: Prior to June 1999, all heavy duty truck wheels manufactured by Alcoa

Wheel Products were date stamped with the month and year only.

Loading...

Loading...