Servicing Work

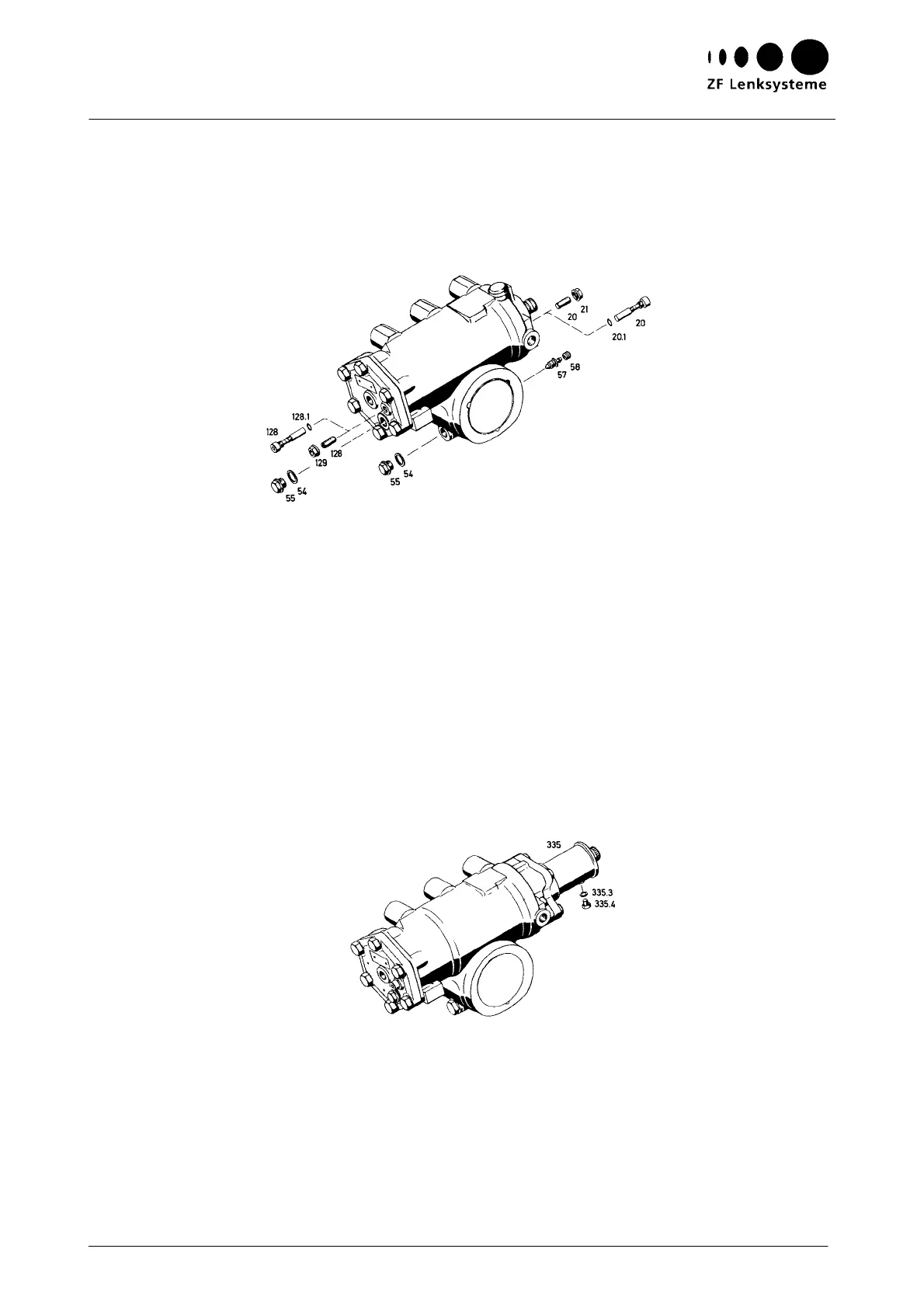

Fig. 7

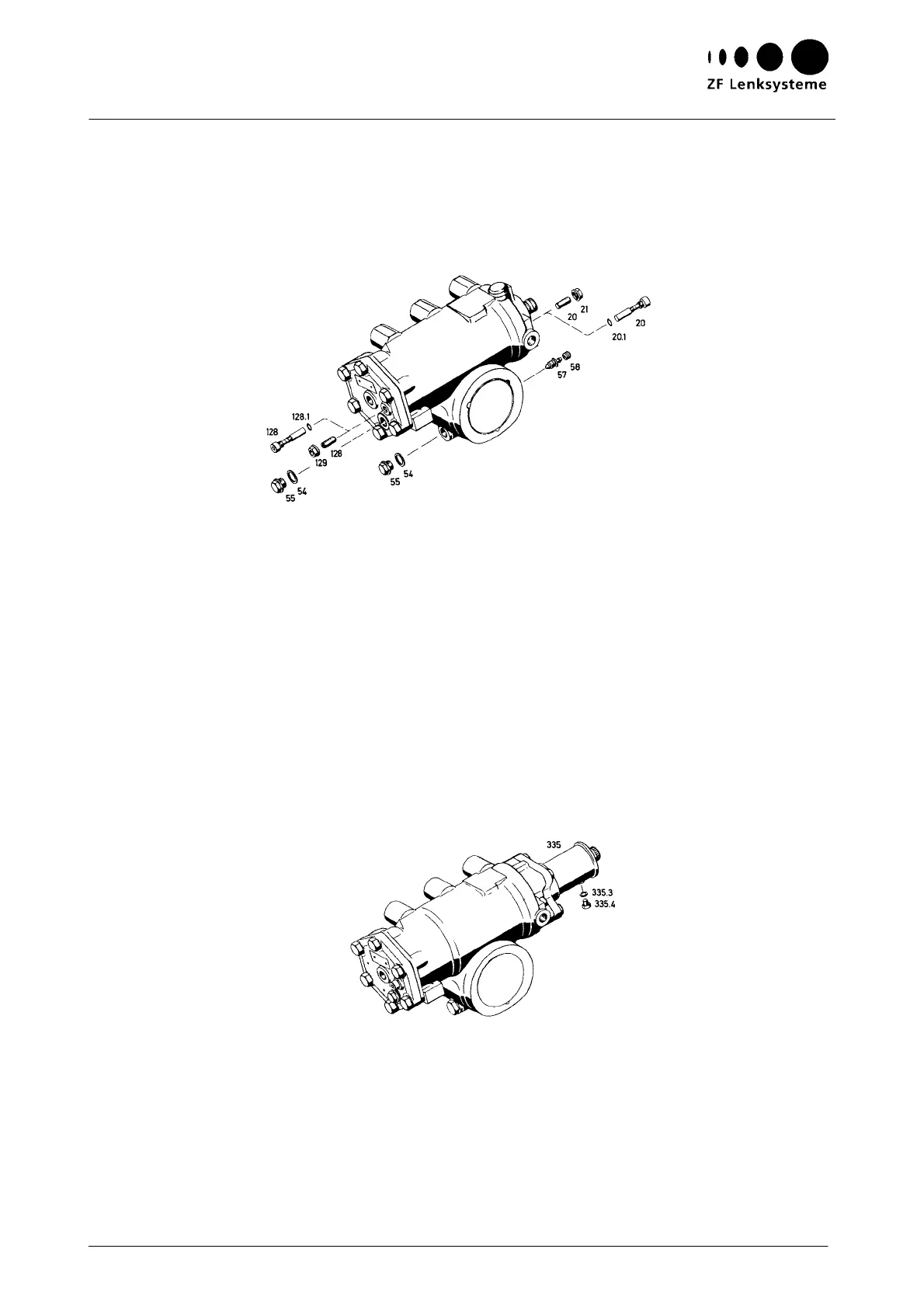

Fig. 8

16 Instructions on Design, Operation, Maintenance and Inspection

V

ersions with bleeder (57):

With the engine running, open the bleeder (57) until nothing but oil is coming out (Fig. 7).

Afterwards, close the bleeder again until it is oil-tight.

On versions without automatic bleeding (installed position horizontal, steering output shaft in the

bottom position) the topmost screw/set screw (20 and 128, respectively) can be used for bleeding.

Versions with screw (20 and 128):

Open the topmost screw (20 and 128, respectively) until nothing but oil is coming out.

Re-tighten the screw (20 or 128) using a torque of 12+3 Nm.

Versions with set screw (20 and 128):

Slacken the collar nut (21 or 129) of the topmost set screw (20 or 128) until nothing but oil is

coming out.

Re-tighten the collar nut (21 and 129) using a torque of 20+10 Nm.

The hydraulic steering limitation must be checked after bleeding.

For versions with flange (335), in addition:

Open the screw plug (335.4) until nothing but oil is coming out (Fig. 8).

Then close the screw plug again.

Tightening torque: 8+1 Nm (M8x1)

If bleeding was done correctly, the oil level in the tank must not rise by more than 1 to 2

cm when the engine is stopped.

Turn the engine off and lower the jacked-up steered axle or drive axle to the ground.

Loading...

Loading...