Section 16: SUSPENSION

PA1562

5

1. DESCRIPTION

The vehicle is provided with an air suspension system. The system consists of air springs, height control

valves, radius rods, sway bars, tripod and shock absorbers (Fig. 1, 2, 11, 36, 37 and 38). The system

operation is fully automatic and maintains a constant vehicle height regardless of load, or load

distribution.

The vehicle can also be equipped with systems such as:

• Front Kneeling (w/ Front High-Buoy);

• Front Kneeling (w/ Full High-Buoy);

• Front Kneeling (w/ Front High-Buoy) and Low-Buoy Combination;

• Front Kneeling (w/ Full High-Buoy) and Low-Buoy Combination;

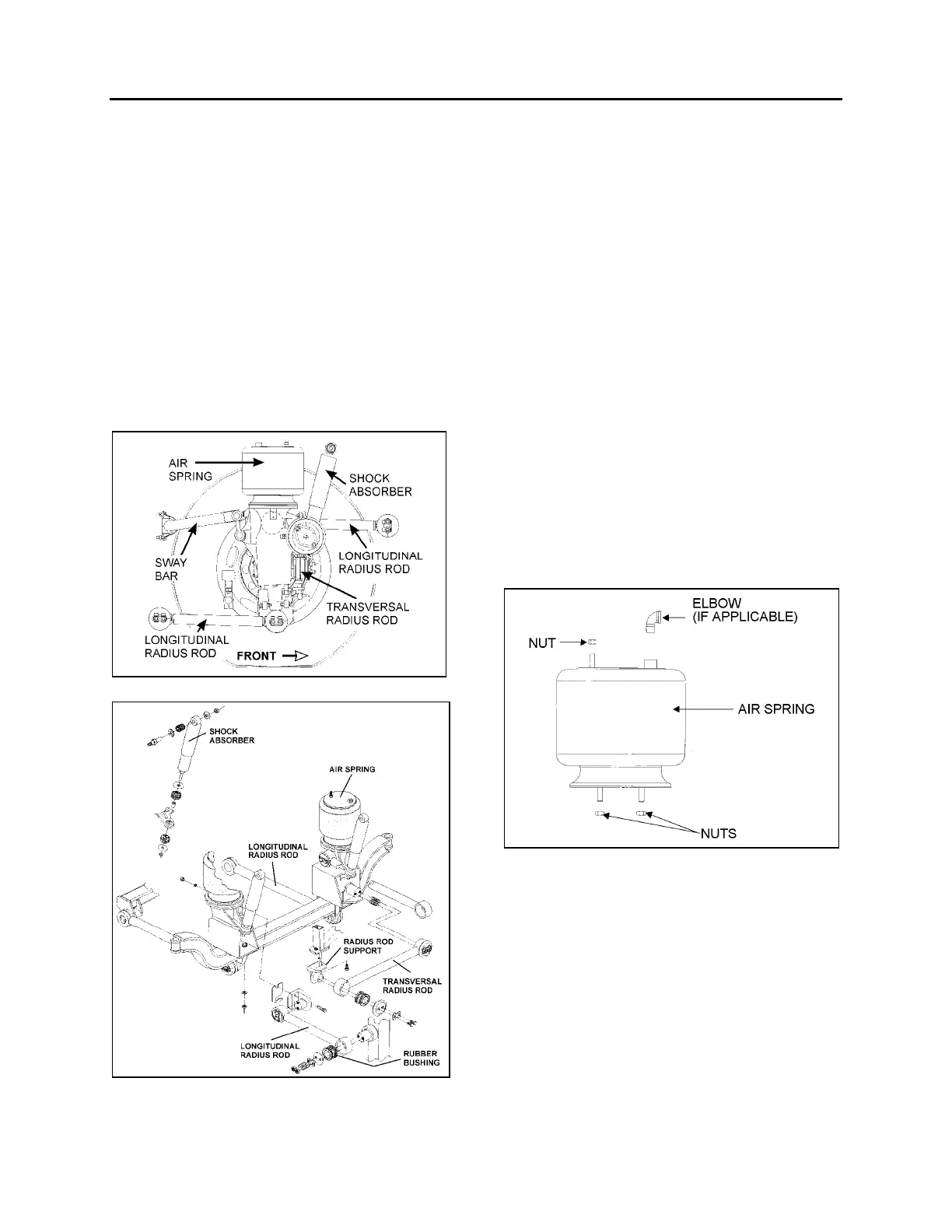

2. I-BEAM AXLE FRONT SUSPENSION

FIGURE 1: FRONT SUSPENSION COMPONENTS

16096

FIGURE 2: DETAILS OF FRONT SUSPENSION 16110

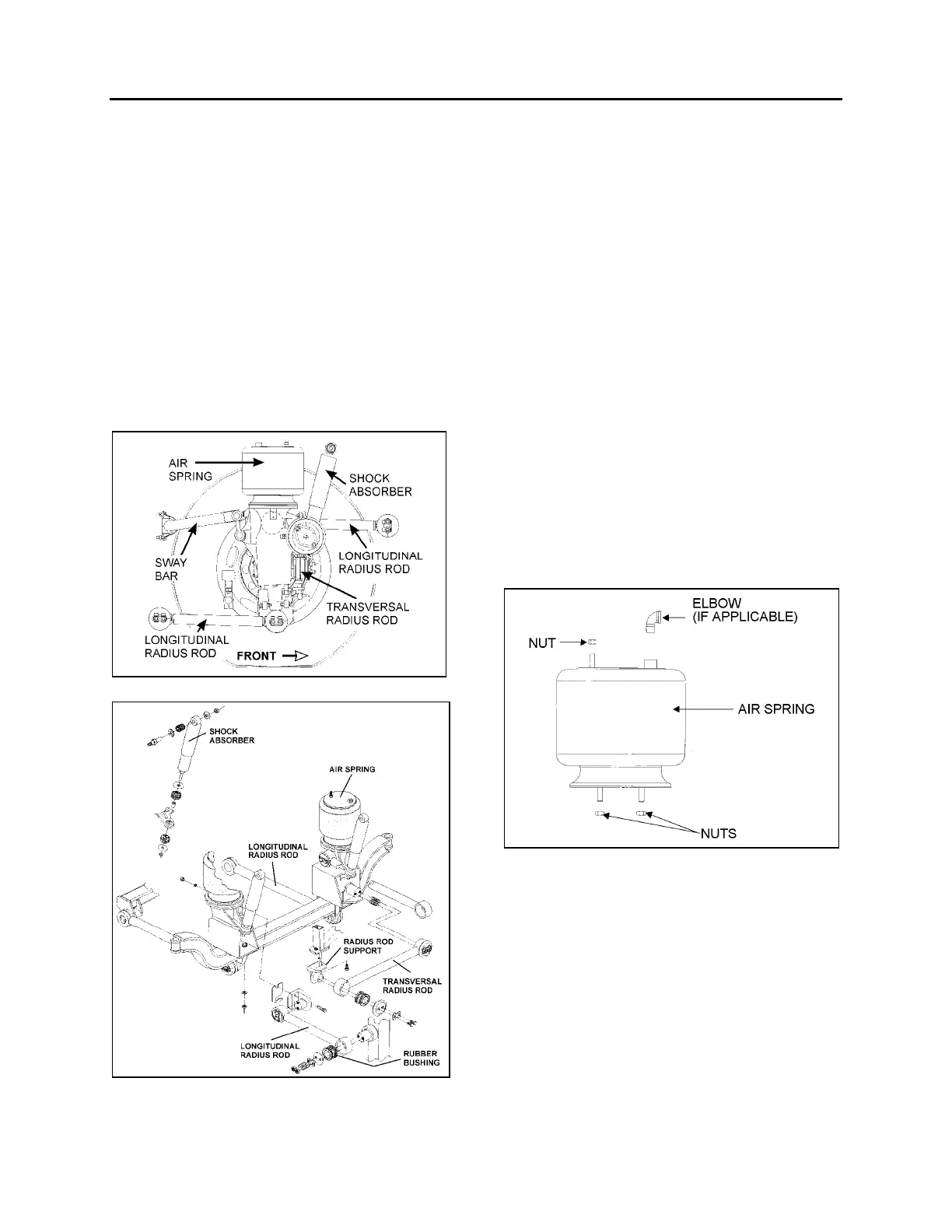

2.1 AIR SPRINGS

The air springs are made from a special

compound rubber molded to the proper contour

and dimensions. The entire vertical load of the

vehicle is supported by these springs. The I-

beam front axle is provided with air springs that

are attached to the subframe and to the axle

(Fig. 3).

FIGURE 3: AIR SPRING 16052

2.1.1 Inspection

1. Check operation of bellows.

2. Visually inspect bellows for evidence of

cracks, punctures, deterioration, or chafing.

Replace the bellows if any damage is

evident.

3. With the primary air system at normal

operating pressure (95 - 125 psi (655 - 860

kPa)), coat all suspension air line

connections and bellows mounting areas

with a water and soap solution. Bubbles will

indicate an air leak, and none is

Loading...

Loading...