Section 16: SUSPENSION

PA1562

10

CAUTION

It is extremely important upon reconnection of

the rods that the proper clearance height

between the axle and body be maintained.

Otherwise, the rubber bushings in radius rod

ends will become preloaded, thus reducing

their life span.

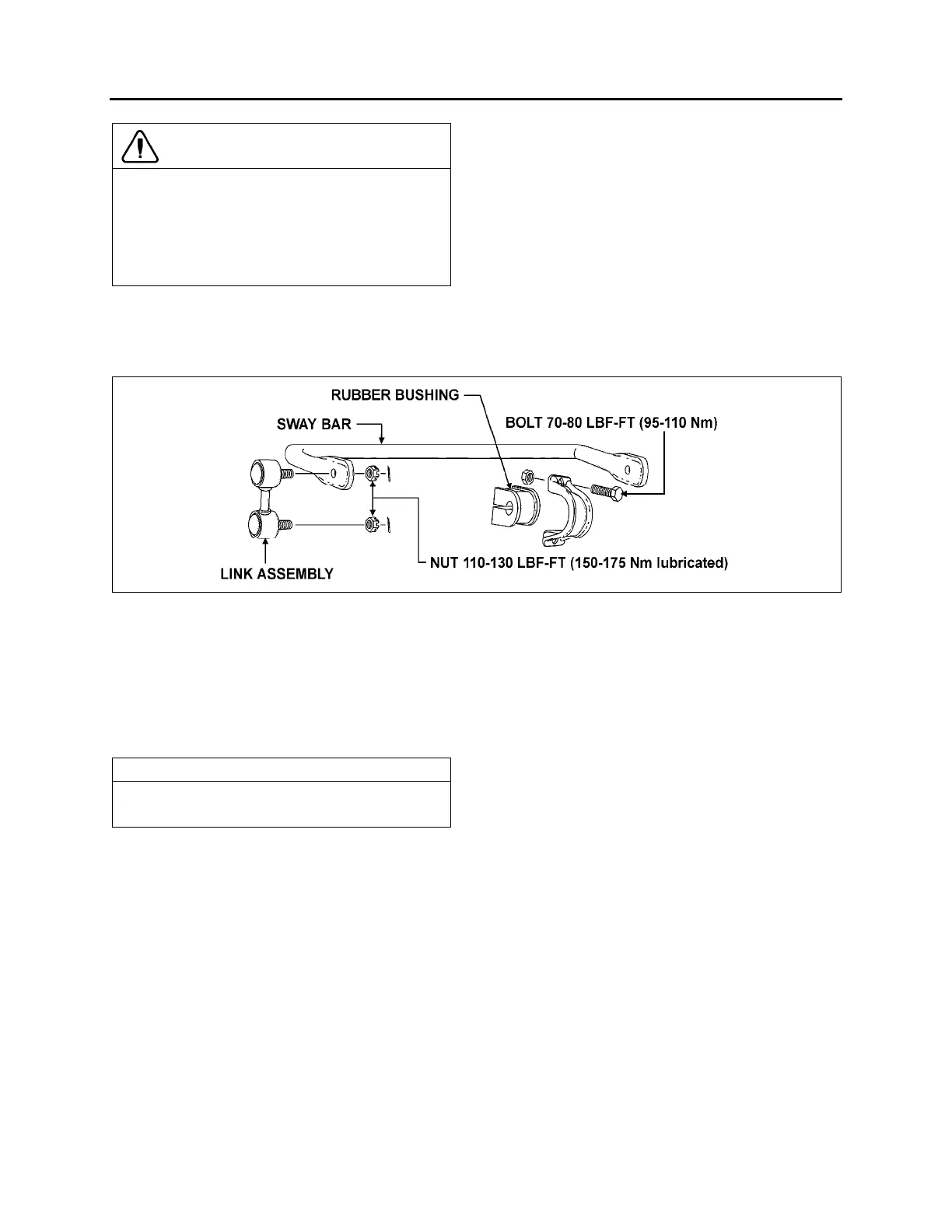

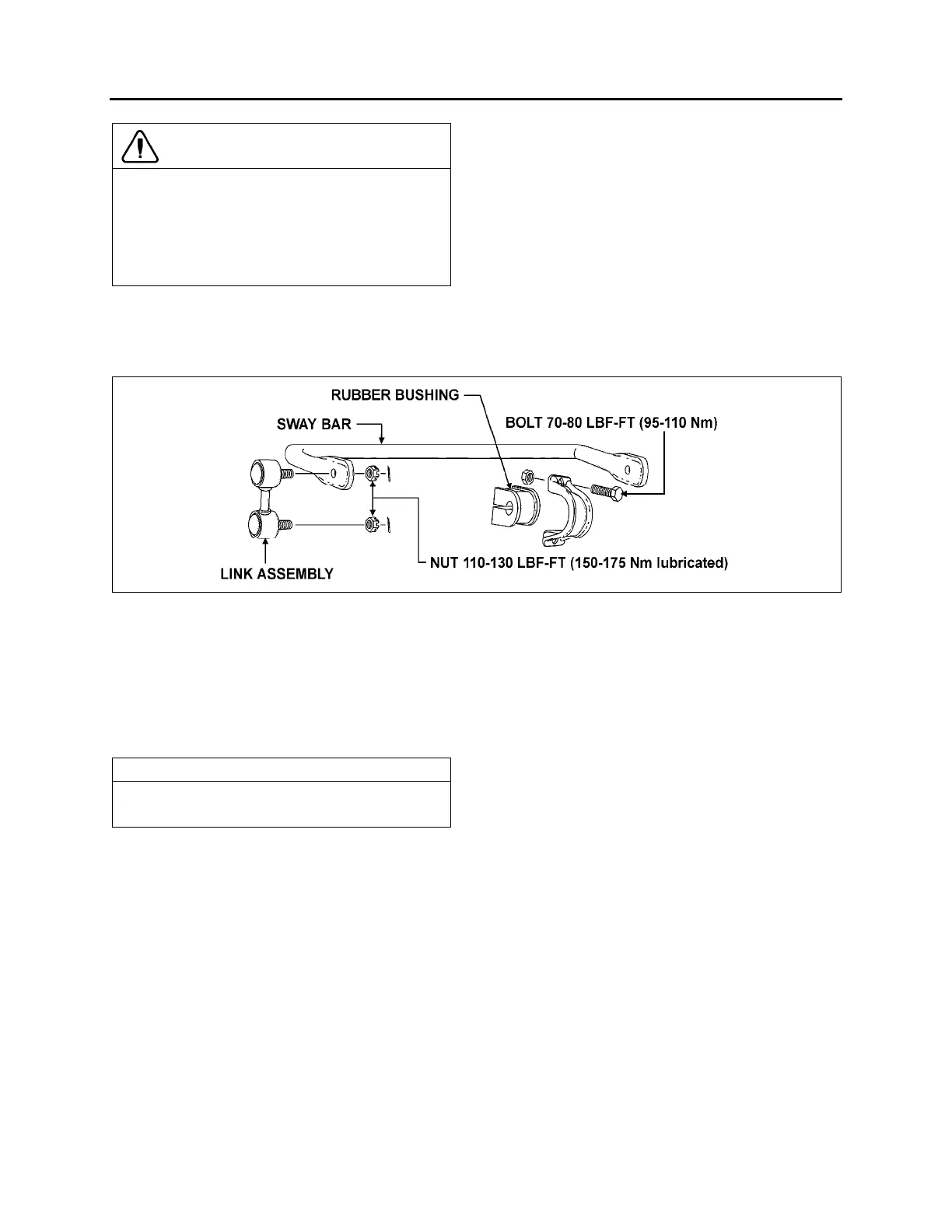

2.4 SWAY BAR

A sway bar is provided on the front axle to increase vehicle stability. It controls lateral motion (swaying

movement) of the vehicle (Fig. 10).

FIGURE 10: I-BEAM FRONT AXLE SWAY BAR 16099

2.4.1 Removal

1. Disconnect the two links from sway bar.

2. Safely support the sway bar. Unbolt the four

bushing collars from subframe.

3. Remove sway bar.

NOTE

Sway bar bushings are slitted to ease their

removal.

2.4.2 Installation

1. Loosely install the sway bar.

2. Tighten the eight bushing collar nuts to 70 -

80 lbf-ft (95 - 110 Nm) (Fig. 10).

3. Install two sway bar link upper and lower

nuts and tighten to 100 - 130 lbf-ft (150 -

175 Nm) (Fig. 10).

4. Install a cotter pin on each nut and bend.

3. INDEPENDENT FRONT SUSPENSION (IFS)

3.1 STEERING LINKAGE

Turning motion of the steering wheel is transferred by the steering gear and steering linkage to the

steering arms at the right and left front wheels. The steering linkage consists of tie rods connected to the

bell crank and the steering arm at the left side of the coach, and to the idler arm and steering arm at the

right side of the coach. The bell crank and idler arm are connected by a relay rod. A drag link connected

to the bell crank and the pitman arm, which is mounted to the steering gear, transfers the turning motion

of the steering wheel to the steering arms (Fig. 11).

Lower and upper A-arms are widely spaced. They are mounted on ball joints. Torque rods prevent

rotation of the uprights around the lower and upper ball joints.

If the steering linkage is bent, twisted or worn, steering action of the coach will be seriously affected. Any

time steering linkage components are replaced or adjusted, steering geometry and front wheel alignment

must be checked as explained in this section.

Loading...

Loading...