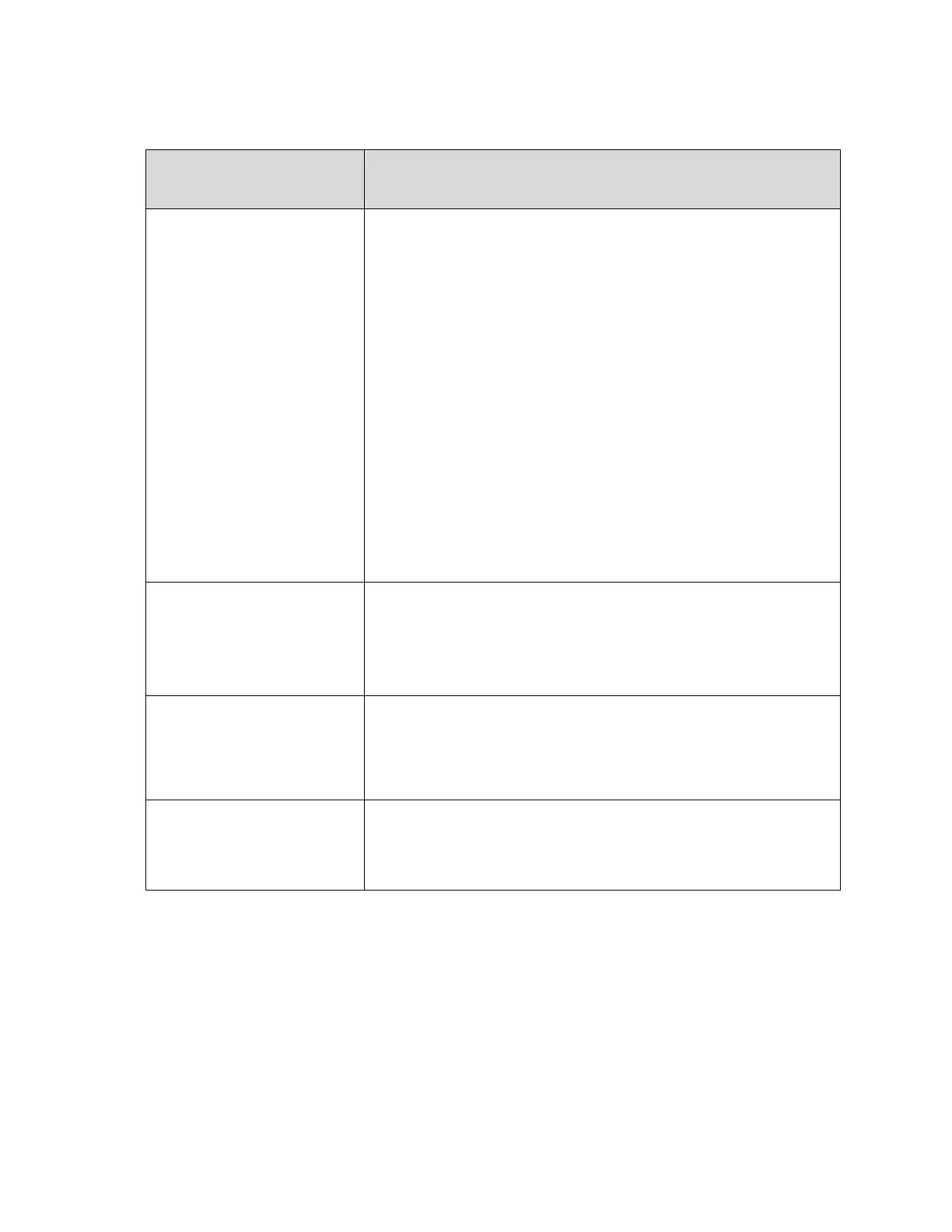

The printer is set for

Gap or Mark sensing,

but a gap, notch, or

black mark is not being

detected.

The lower media

sensor is not

positioned correctly.

Gap/Mark Threshold is

set too high or Paper

Out Threshold is

set

too low.

1.

Check that the setting of

the Gap/Mark Sensor in

the

SESNOR > Control section

matches the

installed media.

2.

Check the position of the

lower and upper media

sensors.

(See Z-axis Mechanism Adjustment Screw on page 33.)

3.

Clean the sensor assembly

and paper path.

4.

Run Auto Calibrate to

improve the sensor’s ability

to detect the

media in use.

5.

Run the Sensors > Diagnostic > Media Profile.

6.

Run Manual Calibrate.

(See Running Manual Calibrate

page 42.)

7.

Manually change the Gap/

Mark Threshold and/or

Paper

Out Threshold

values.

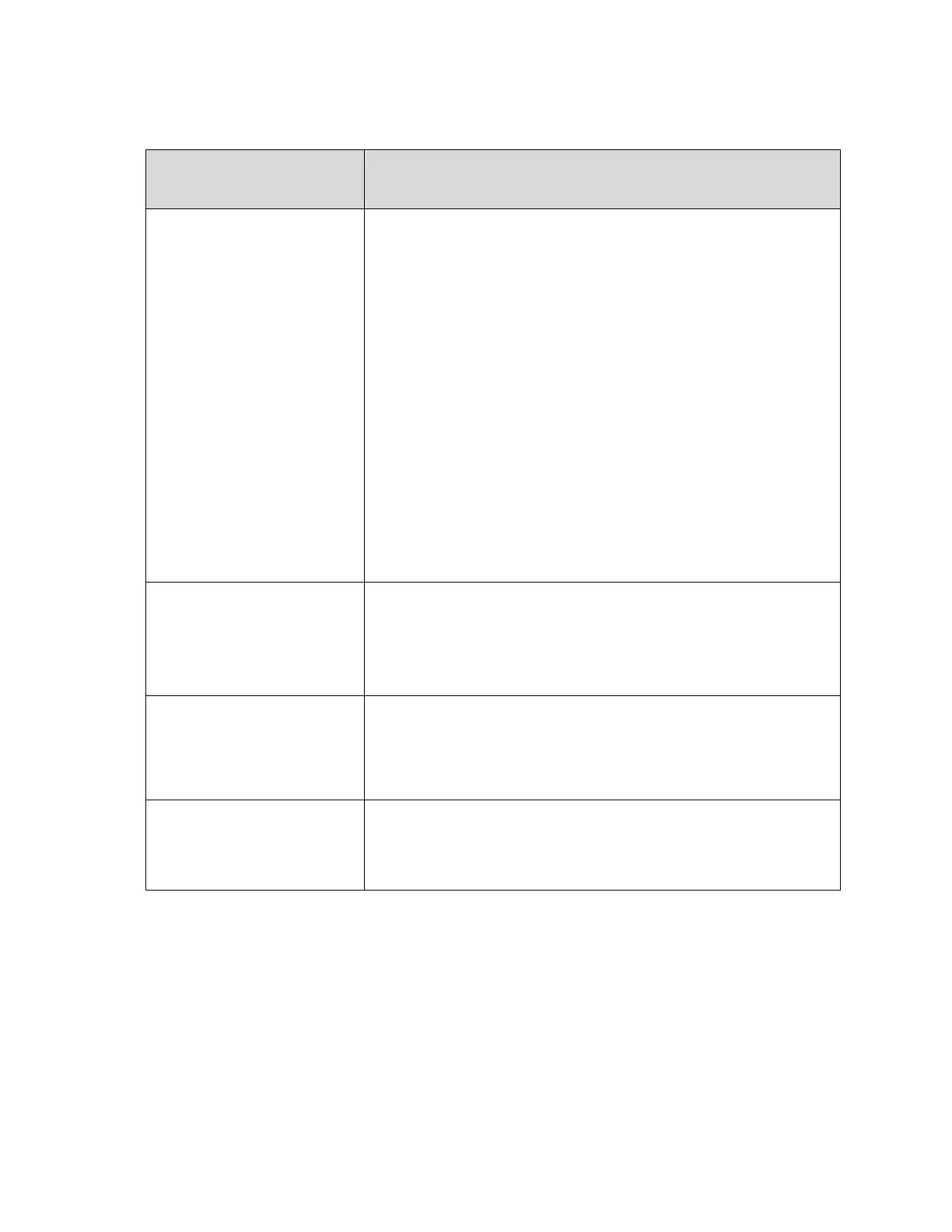

Status message indicating that the GPIO option card FPGA failed

to program.

1. Pressing any key on the panel will cause the printer to continue

boot-up with the previous FPGA configuration.

Loading...

Loading...