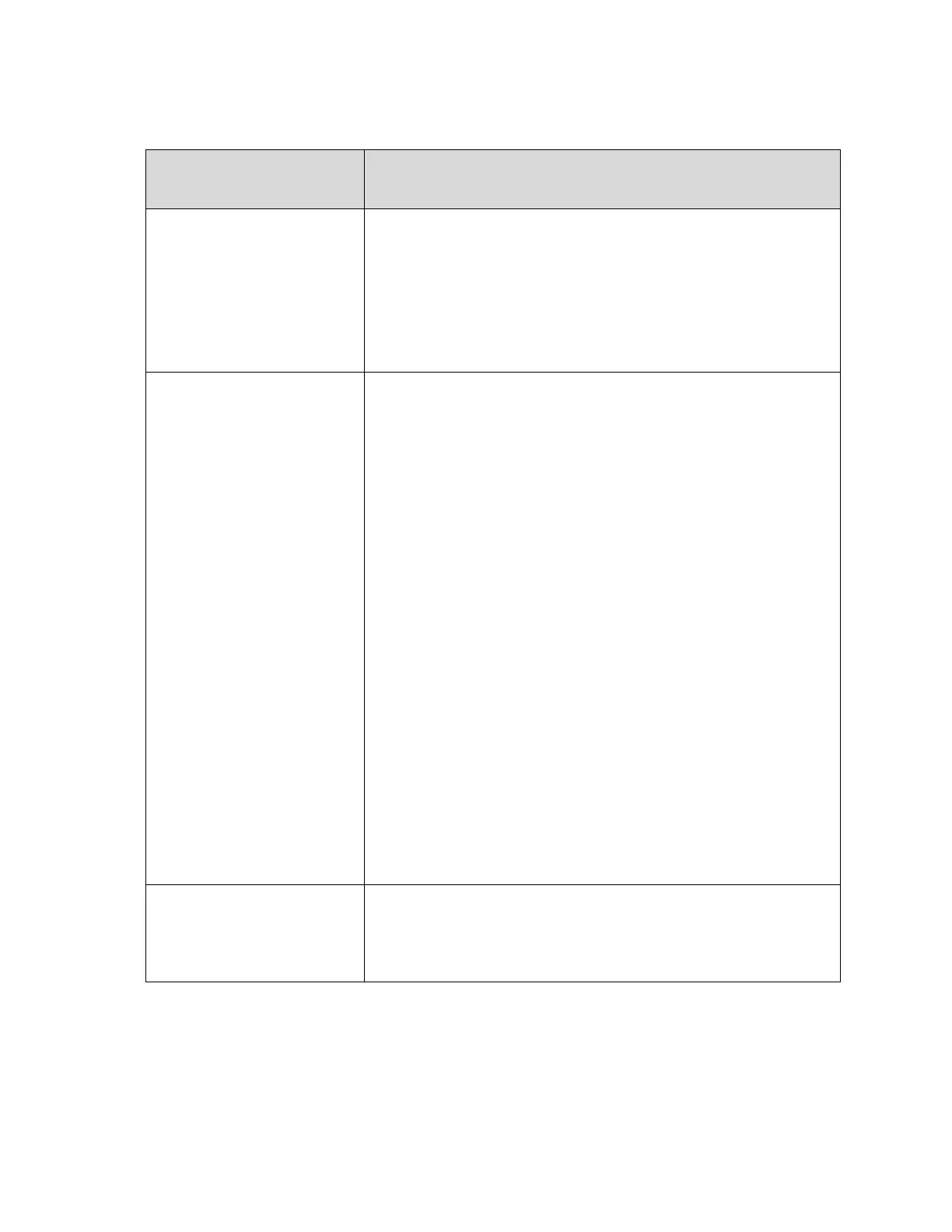

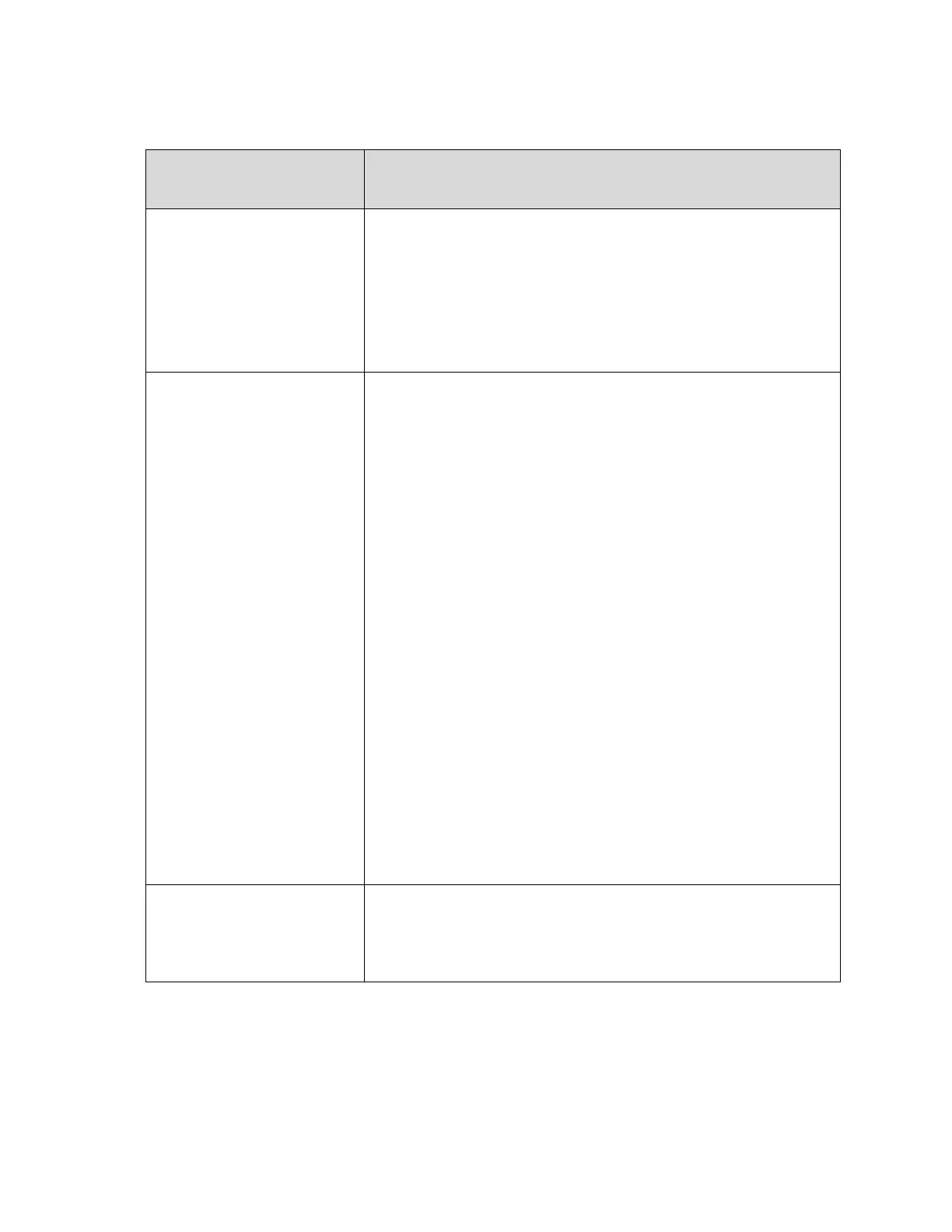

Table 13. LCD Message Troubleshooting

Overall data validation

failure: decodeability,

percent decode,

defects, modulation,

EC Min, Rmin, and/or

symbol contrast.

1.

Press Pause to clear the

message.

2.

Adjust the parameter that

is causing the failure. Run

a

Validator > Diagnostics > Scan Report to see

which parameter

failed.

3.

Lower the Validator > Grading > Overall Grade to

a point where

the worst

parameter grade will be

above this threshold.

The printer does not

sense media:

• Media was not

installed or has run

out.

• A break in media

has occurred.

• Media was not

routed or installed

correctly.

• The media sensor

is not positioned

correctly.

• Media is installed

correctly, but the

sensor is not

detecting it.

• Sensors > Control > Gap/Mark

Thresh value

may be set too

high and/or Sensors > Control > Paper

Out Thresh may

be set

too low.

• The printer

detected a false

PAPER OUT when

changing to

Gap or Mark

sensing or vice-

v

ersa.

1.

Install media. If a break

occurred, reinstall the

media. Press

the PAUSE

key to clear the fault

message.

2.

Verify the lower media

sensor is properly

positioned under the

media. Run Auto Calibrate

to improve the ability of the

sensor

to detect the

installed media.

3.

Check if the Gap/Mark

Threshold is too high or the

Paper Out

Threshold is too

low. Lower the Gap/Mark

Threshold or raise

the

Paper Out Threshold

value.

4.

If using media with no gaps

or black marks, perform

Auto

Calibrate to establish

a valid Paper Out

Threshold.

5.

If the printer detected a

false PAPER OUT when

changing to

Gap or Mark sensing or

vice-versa, press the

PAUSE key and

run Auto

Calibrate.

Parity error (serial

interface).

1.

Check your serial host

interface parameter settings. If

necessary, change them so

they match the settings of the

attached host.

Loading...

Loading...