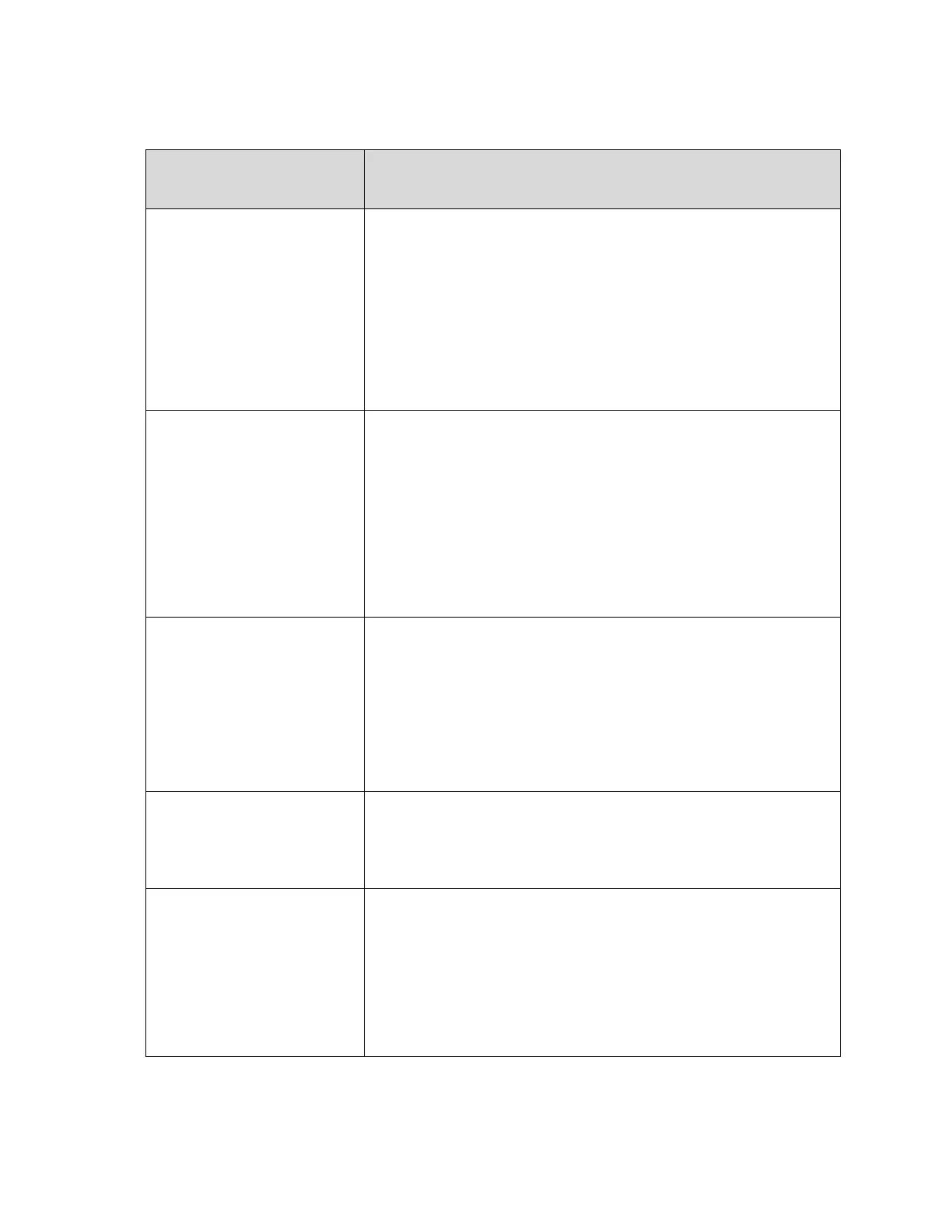

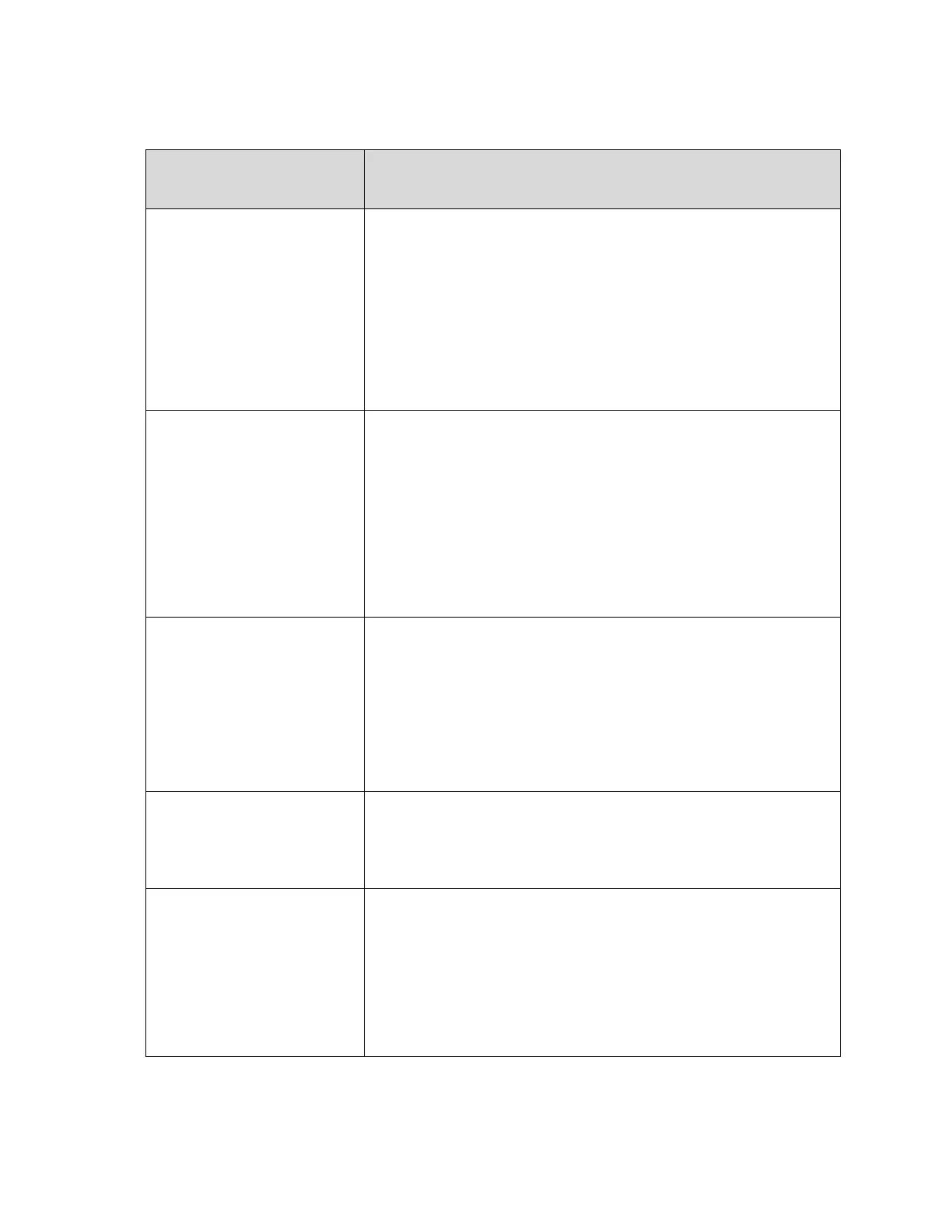

Table 13. LCD Message Troubleshooting

POOR SCANNING

Check Head&Heat

Data validation failure: percent decode. The validator detected

gross inconsistencies within the height of the bar code. These types

of failures are likely attributed to large blemishes within the bar

code, caused by ribbon wrinkle or debris on media.

1.

Check for a wrinkled ribbon or debris on media. Roll wrinkled

area onto take-up spindle.

2.

Adjust the printhead pressure blocks.

3.

Modify Media > Image > Print Intensity or Media > Speed >

Print Speed.

POOR SCANNING

Check media

Data validation failure: percent decode. The validator detected

gross inconsistencies within the height of the bar code. These types

of failures are likely attributed to large blemishes within the bar

code, caused by ribbon wrinkle or debris on media.

1.

Check for a wrinkled ribbon or debris on media. Roll wrinkled

area onto take-up spindle.

2.

Adjust the printhead pressure blocks.

3.

Modify Media > Image > Print Intensity or Media > Speed >

Print Speed.

POOR SCANNING

Inspect head

Data validation failure: hardware defect. The validator detected

unexpected dark spots in spaces or light spots in bars. This usually

indicates a poor ribbon/media combination, a dirty printhead, or a

burned pixel.

1.

Check paper and ribbon to

make sure they are clean,

unwrinkled, and installed

properly.

2.

Clean printhead.

3.

If message persists,

replace the printhead.

This is a status

message. The printer

is in low-energy idle

state, the

fan and

higher voltages are off,

and only +5Vdc logic

circuits are

active.

No action required.

Printer is in a cold

environment or

the printhead data cable has

become dislodged

from the back of the

printhead or the controller.

1.

Reseat the cables on printhead.

2.

Change the printhead.

3.

Place printer in a warmer

location.

4.

If problem persists, contact

your authorized service

representative.

Loading...

Loading...