701 Motor Protection Relay Date Code 20010719

Commissioning

Selected Functional Tests

7.14

NOTE: Changing settings requires that you enter the Access

Level 2 password. The factory password is 701.

Step 3. Set the current source phase angles to apply balanced three-phase

currents. Refer to Figure 7.1 on page 7.4 for the correct angles, which

depend on the PHROT setting.

Step 4. Reset the motor thermal element using the front-panel Reset Thermal

Model function.

NOTE: This function requires that you enter the Access Level 2

password. The factory password is 701.

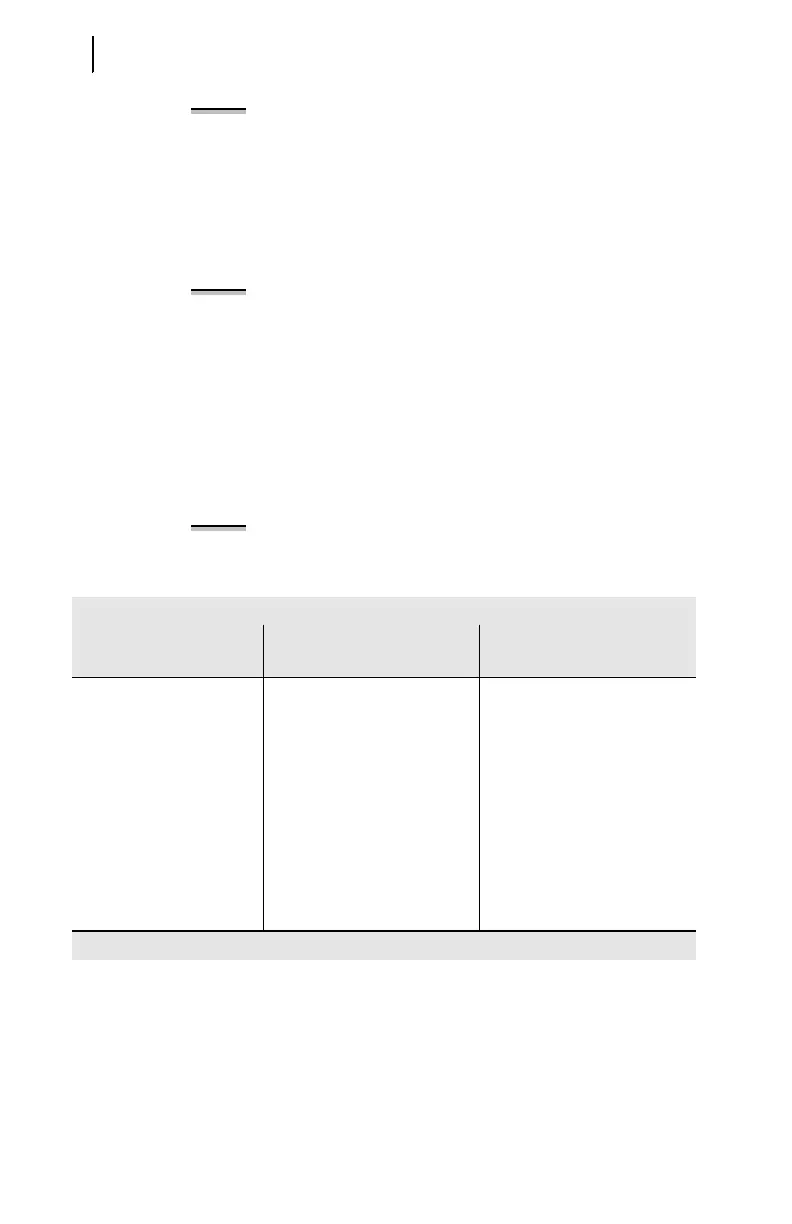

Set the current sources to apply the test current shown in Table 7.6,

then turn on the current sources together. Refer back to Table 7 .6 to

determine the expected element operating time. For instance, when

the setting CURVE is equal to 4, the thermal element should trip in

4•10 = 40 seconds when applied three-phase current equals three

times the motor full load current setting, FLA. Use the front-panel

Meter Values\Thermal & RTD Data function to view the estimated

Time to Thermal Trip during each test.

NOTE: Reset the motor thermal model before each test run or

the element will trip faster than expected.

Table 7.6 Th erma l Element Ex pected Trip Times

Table 7.6 Thermal Element Expected Trip Times

Applied

Current (A secondary)

Expected Time to Trip (s)

Measured Time to Trip (s)

1.2 • FLA CURVE • 145.7

1.5 • FLA CURVE • 51.5

2.0 • FLA CURVE • 23.3

3.0 • FLA CURVE • 10.0

4.0 • FLA CURVE • 5.63

5.0 • FLA CURVE • 3.60

6.0 • FLA CURVE • 2.50

7.0 • FLA CURVE • 1.84

Loading...

Loading...