Date Code 20010719 701 Motor Protection Relay

Settings Calculation

Basic Motor Protection

4.11

Thermal Element GENERIC Setting Method

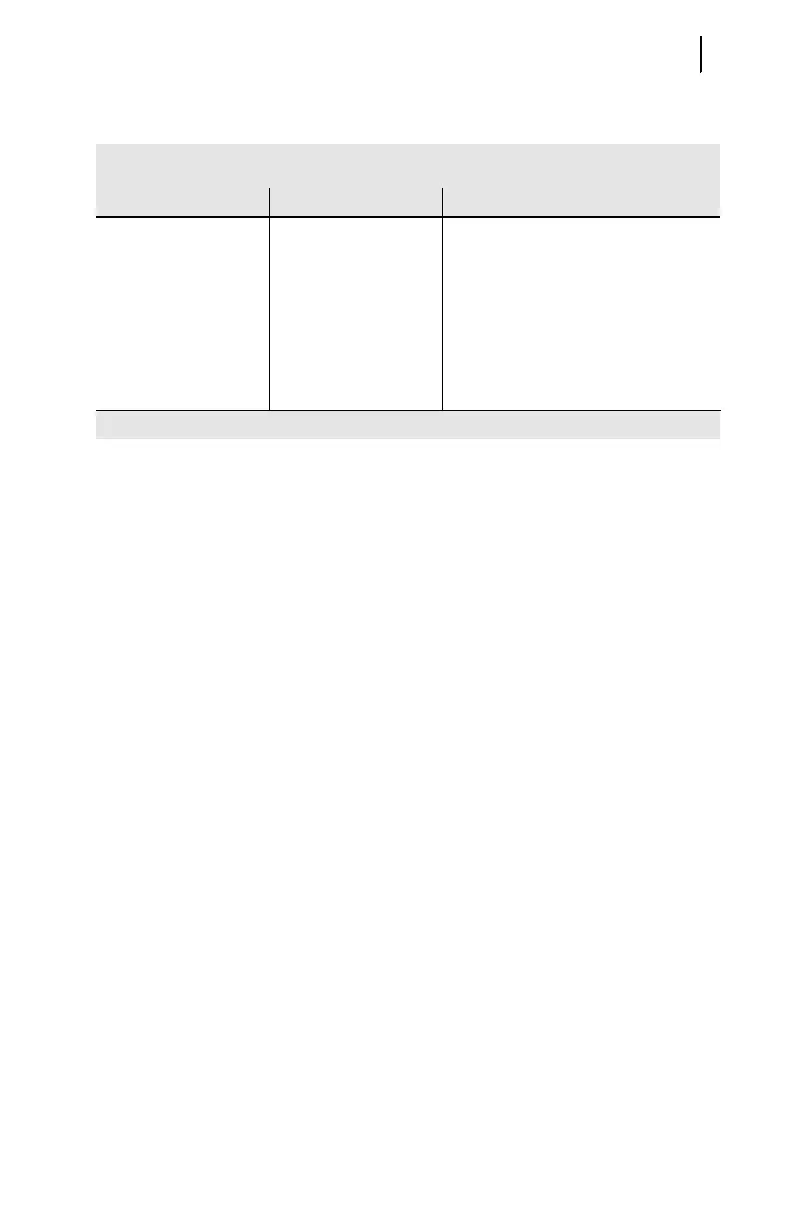

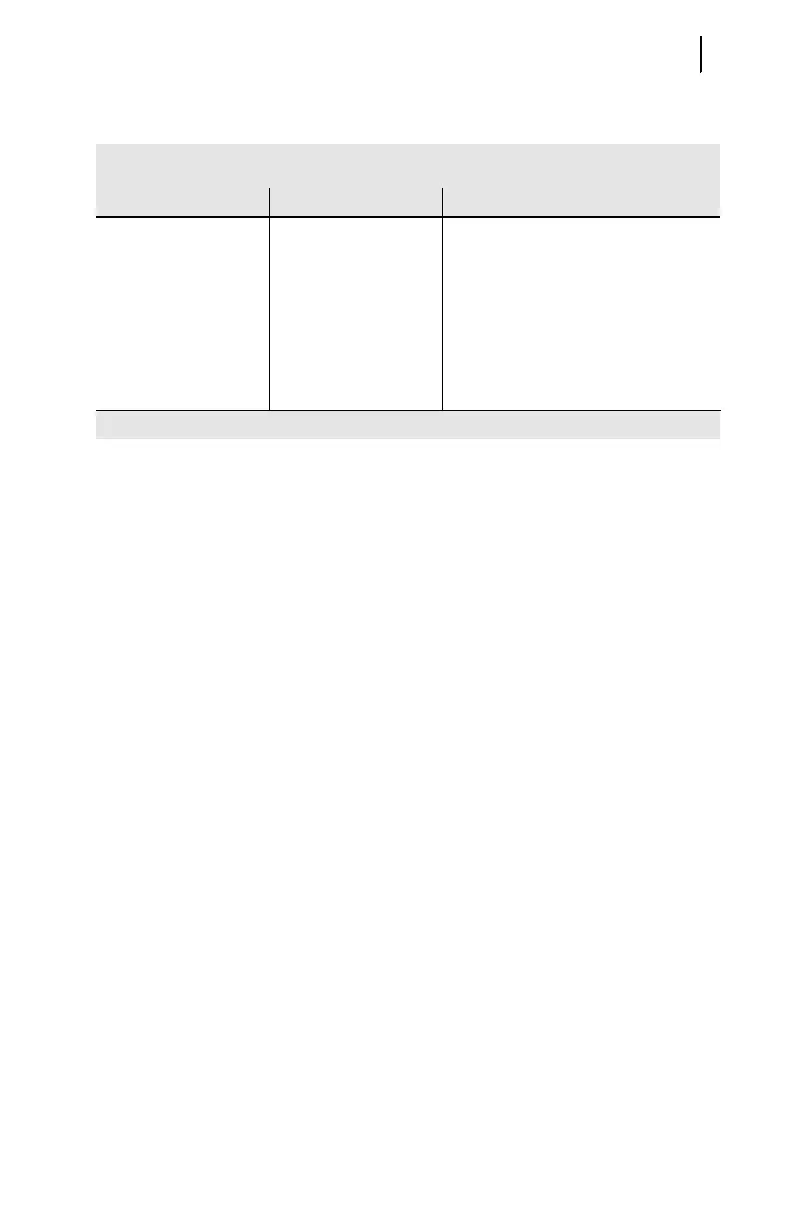

Table 4.6 Therma l Element Configu ration Setting s, Setting Method = GE NERIC

For simple, yet thorough motor protection, you may elect to use one of the 45

available standard motor overload/locked rotor curves. Set the motor rated Full Load

Amps and Service Factor, then select the desired curve from Figure 4.2 on page 4.13.

Be sure that the standard curve you select trips in a time less than or equal to the

motor rated locked rotor time at locked rotor current. Each increase in the curve

number yields a 2.5-second increase in the curve thermal limit time at six times full

load current. For a cold motor, the curve 10 trip time at six times full load current is

25 seconds. Table 4.7 on page 4.14 and Table 4.8 on page 4.15 show the cold motor

thermal limit time versus current for several curves.

Each increase in the curve number yields a 2.1-second increase in the hot motor

thermal limit time at six times full load current.

Continue calculating the balance of thermal element settings with Thermal

Capacity Alarm Setting on page 4.21.

Table 4.6

Thermal Element Configuration

Settings, Setting Method = GENERIC

Setting Prompt Setting Range Setting Name = Example Setting

Setting Method Rating, Generic, User SETMETH = GENERIC

Full Load Amps 1.00–8.00 A

ITAP = 5 A

0.20–1.60 A

ITAP = 1 A

FLA = 5.00

FLA = 1.00

Service Factor 1.00–1.50 SF = 1.15

Curve Number 1–45 CURVE = 1

Loading...

Loading...