•

Supplement t

o prevent reaching over

•

Height of the scan plane

•

Switching time between monitoring cases, if applicable

Calculate the minimum distance S using the following formula (see ISO 13855):

b

S = (K × (T

M

+ T

S

)) + Z

G

+ Z

R

+ C

where

•

K = Approach speed (1,600 mm/s, defined in ISO 13855)

•

T

M

= Stopping time of the machine or system

•

T

S

= Response time of the safety laser scanner and the downstream controller

•

Z

G

= General supplement = 100 mm

•

Z

R

= Supplement for reflection-related measurement errors

•

C = Supplement to prevent reaching over

Response time T

S

of t

he safety laser scanner

The response time T

S

of the safety laser scanner depends on the:

•

Basic response time of the safety laser scanner

•

Set multiple sampling

Supplement Z

R

f

or reflection-related measurement errors

DANGER

P

ersons or parts of the body to be protected may not be recognized or not recognized in

time in case of non-observance.

Retro-reflectors at a distance of less than 1 m from the protective field boundary can

dazzle the safety laser scanner and impair its detection capability.

b

Avoid retro-reflectors at a distance of less than 1 m to the protective field bound‐

ary.

b

If retro-reflectors are nevertheless mounted at a distance of less than 1 m from

the protective field boundary, add a supplement Z

R

= 200 mm to the protective

field.

Supplement C to protect against reaching over

W

ith a protective field installed horizontally, there is a risk of people reaching over the

protective field and thereby reaching the hazardous area before the safety laser scan‐

ner shuts down the dangerous state. You need to allow for this by incorporating a sup‐

plement into the calculation of the minimum distance. This will prevent people from

reaching over the protective field and getting into a hazardous situation (see

ISO 13857) before the safety laser scanner responds.

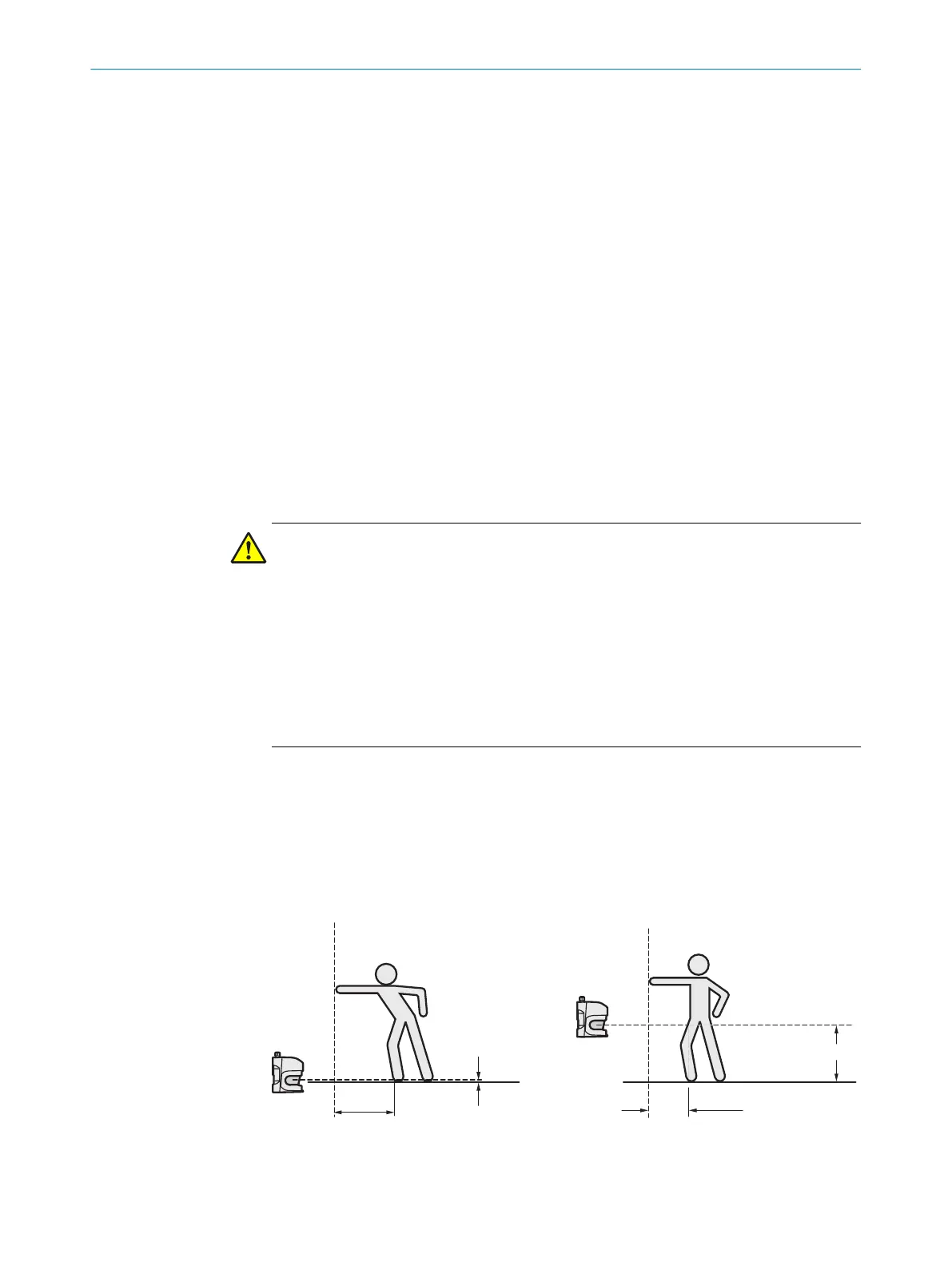

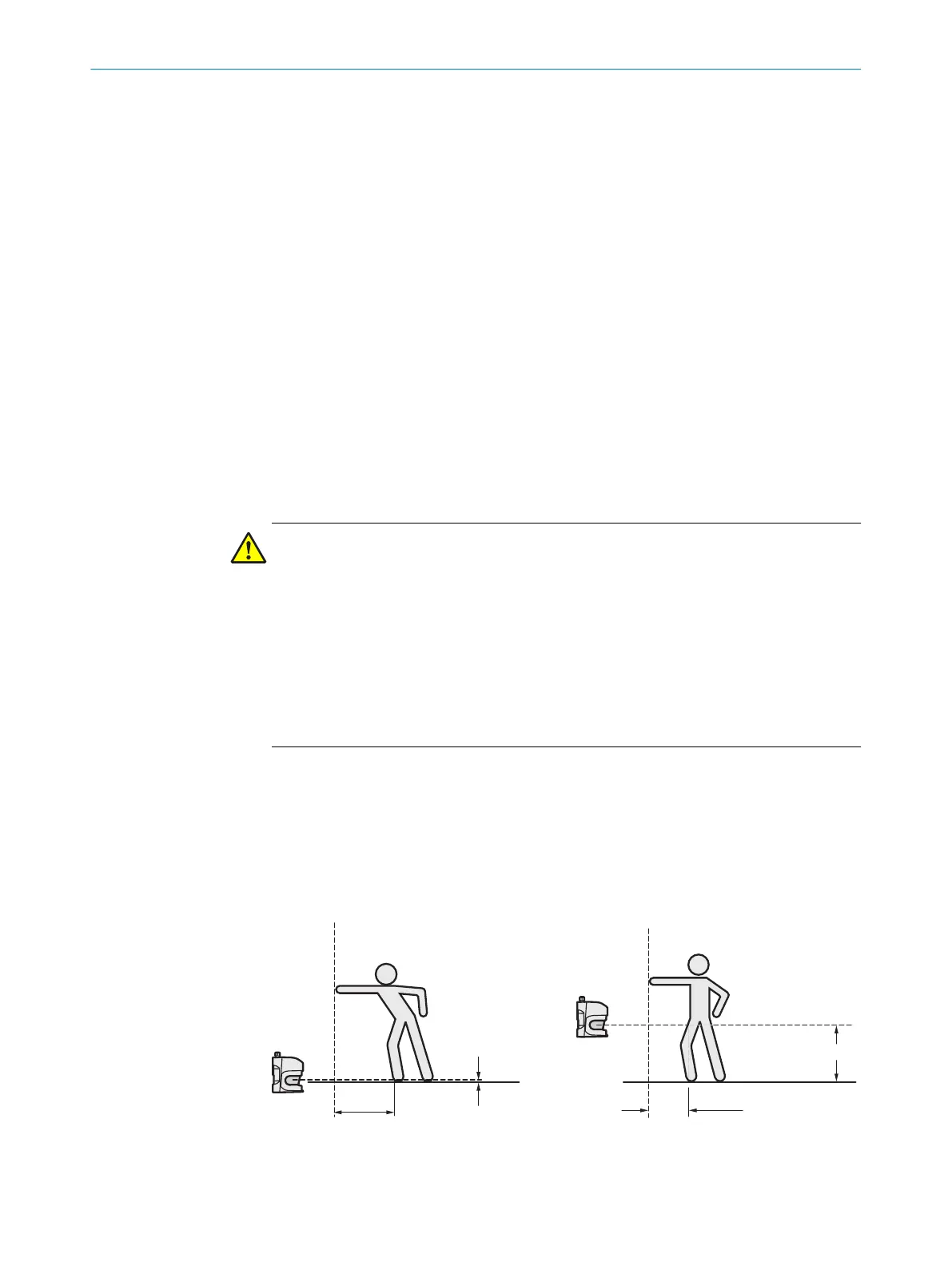

1 2

H

D

= 0

C = 1200 C = 850

H

D

= 875

Figure 30: Risk of reaching over (mm)

4 PROJECT PLANNING

38

O P E R A T I N G I N S T R U C T I O N S | S3000 PROFINET IO, S3000 PROFINET IO-OF 8013291/ZA19/2019-11-14 | SICK

Subject to change without notice

Loading...

Loading...