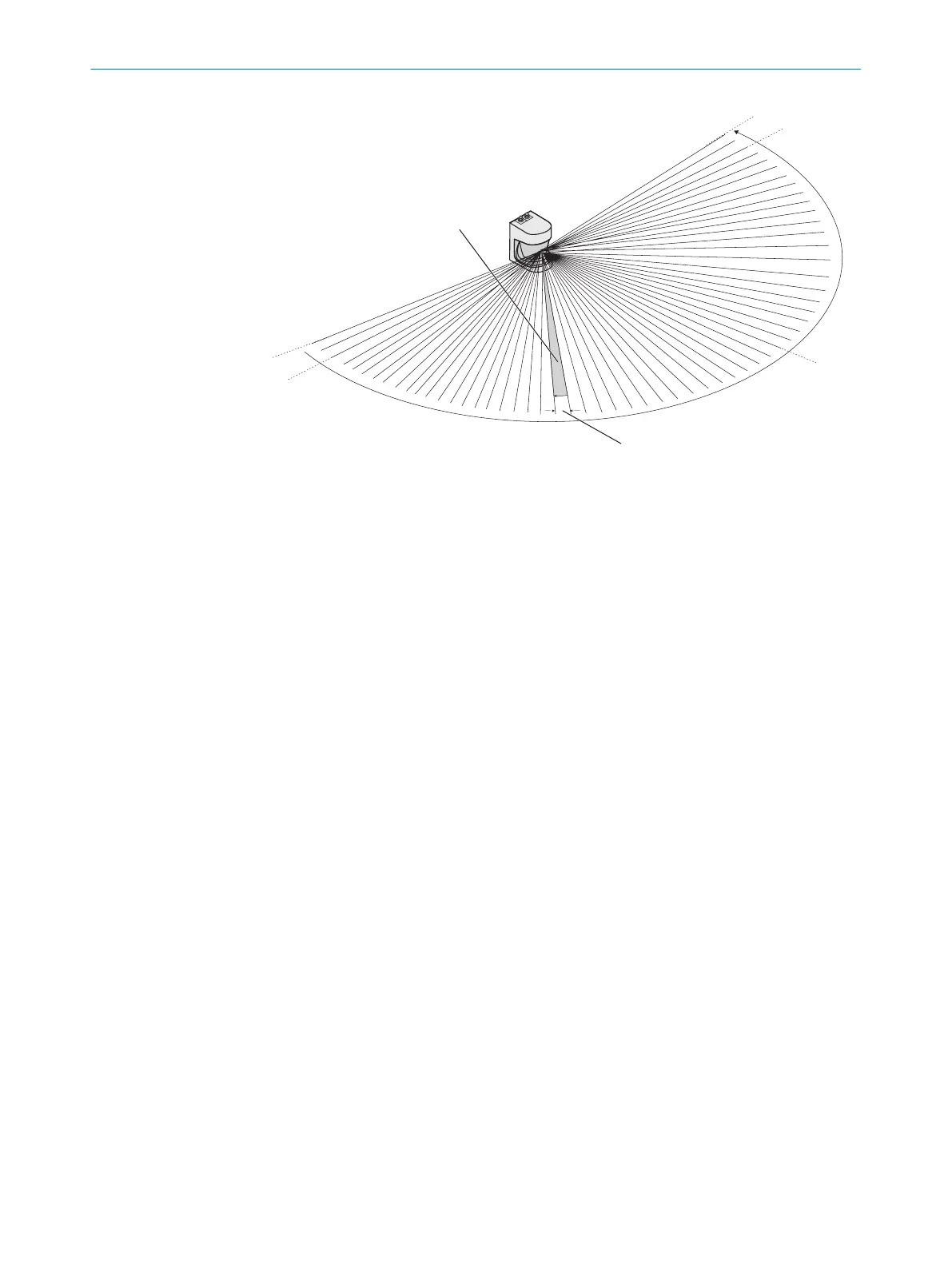

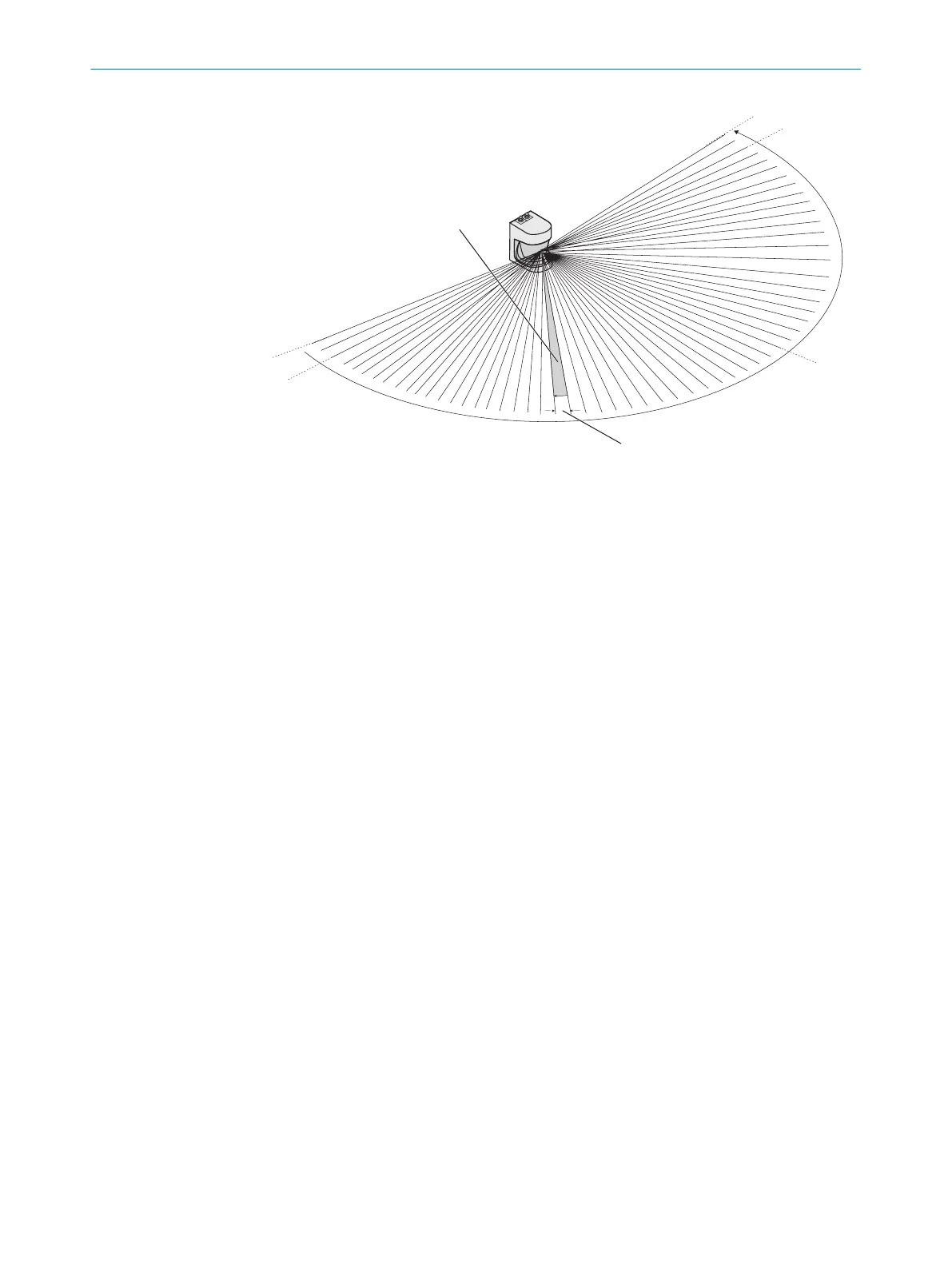

Figure 3: Principle of operation of the safety laser scanner rotation

1

Angular resolution

2

Object resolution

The device also contains a uniformly rotating mirror. The mirror deflects the light pulses

so that they extend over a 190° sector of a circle. This means an object in the protec‐

tive field can be detected within 190°. The first beam of a scan begins at −5° in rela‐

tion to the rear side of the safety laser scanner.

The device emits the light pulses with an angular resolution of 0.25 or 0.5° 1. This

enables resolutions between 30 mm and 150 mm to be achieved 2.

Thanks to the active scanning principle, the safety laser scanner does not need exter‐

nal receivers or reflectors. This has the following advantages:

•

The installation process requires very little time or effort.

•

The monitored area can be easily adapt to the hazardous area of the machine.

•

In contrast to tactile sensors, non-contact scanning is nearly wear-free.

Contour monitoring

In addit

ion to the protective field, the safety laser scanner can also monitor a contour

(e.g., the floor in vertical applications).

Mode of operation

The safety laser scanner can only fulfill its protective function if the following require‐

ments are satisfied:

•

It must be possible to influence the machine, system or vehicle control electrically.

•

It must be possible to change the dangerous state of the machine, the system or

the vehicle into a safe state at any time using the safety laser scanner. That is,

before the person reaches the hazardous points or hazardous areas.

•

The safety laser scanner must be arranged and configured in such a manner that

it can detect objects entering into the hazardous area.

•

The optical path of the safety laser scanner must be kept clear at all times and

must also not be obscured by transparent objects such as protective screens, plex‐

iglass, lenses, etc. The protective function of the safety laser scanner can only be

guaranteed if the contamination measurement function is not circumvented by

such measures.

3 P

RODUCT DESCRIPTION

14

O P E R A T I N G I N S T R U C T I O N S | S3000 PROFINET IO, S3000 PROFINET IO-OF 8013291/ZA19/2019-11-14 | SICK

Subject to change without notice

Loading...

Loading...