Figure 5-13 Minimum and maximum motor frequency

CAUTION

Material damage caused by unexpected acceleration of the motor

Depending on the Power Module, the inverter sets the minimum frequency p1080 to 20% of

the maximum frequency. Also for a setpoint = 0, for p1080 > 0, after the motor is switched

on it accelerates to the minimum frequency. An unexpected acceleration of the motor can

cause material damage.

● If the application requires a minimum frequency = 0, then set p1080 = 0.

Scaling of analog input 0

I

6HWSRLQW

3

3

W

I

PD[

3

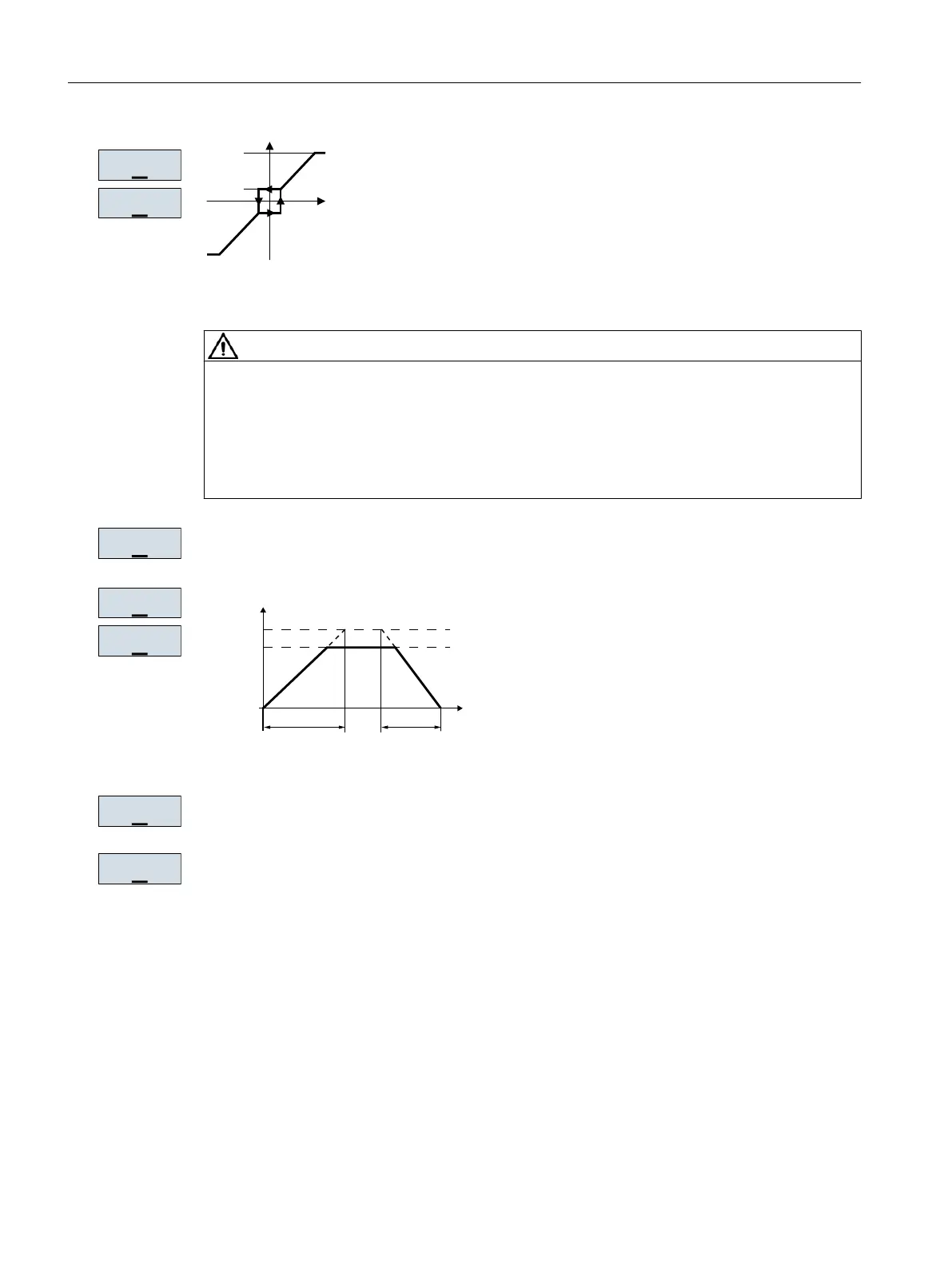

Figure 5-14 Ramp-up and ramp-down time of the motor

Ramp-down time for the OFF3 command

Motor data identification: Select the method which the inverter uses to measure the data of

the connected motor:

● OFF: Motor data is not measured.

● STIL ROT: Recommended setting: Measure the motor data at standstill and with the motor

rotating. The inverter switches off the motor after the motor data identification has been

completed.

3

5$0383

3

5$03':1

Commissioning

5.4 Quick commissioning using the BOP-2 operator panel

Converter with the CU230P-2 Control Units

170 Operating Instructions, 09/2017, FW V4.7 SP9, A5E34257946B AE

Loading...

Loading...