STOBER 8 | Connection

12/2018 | ID 442537.05

73

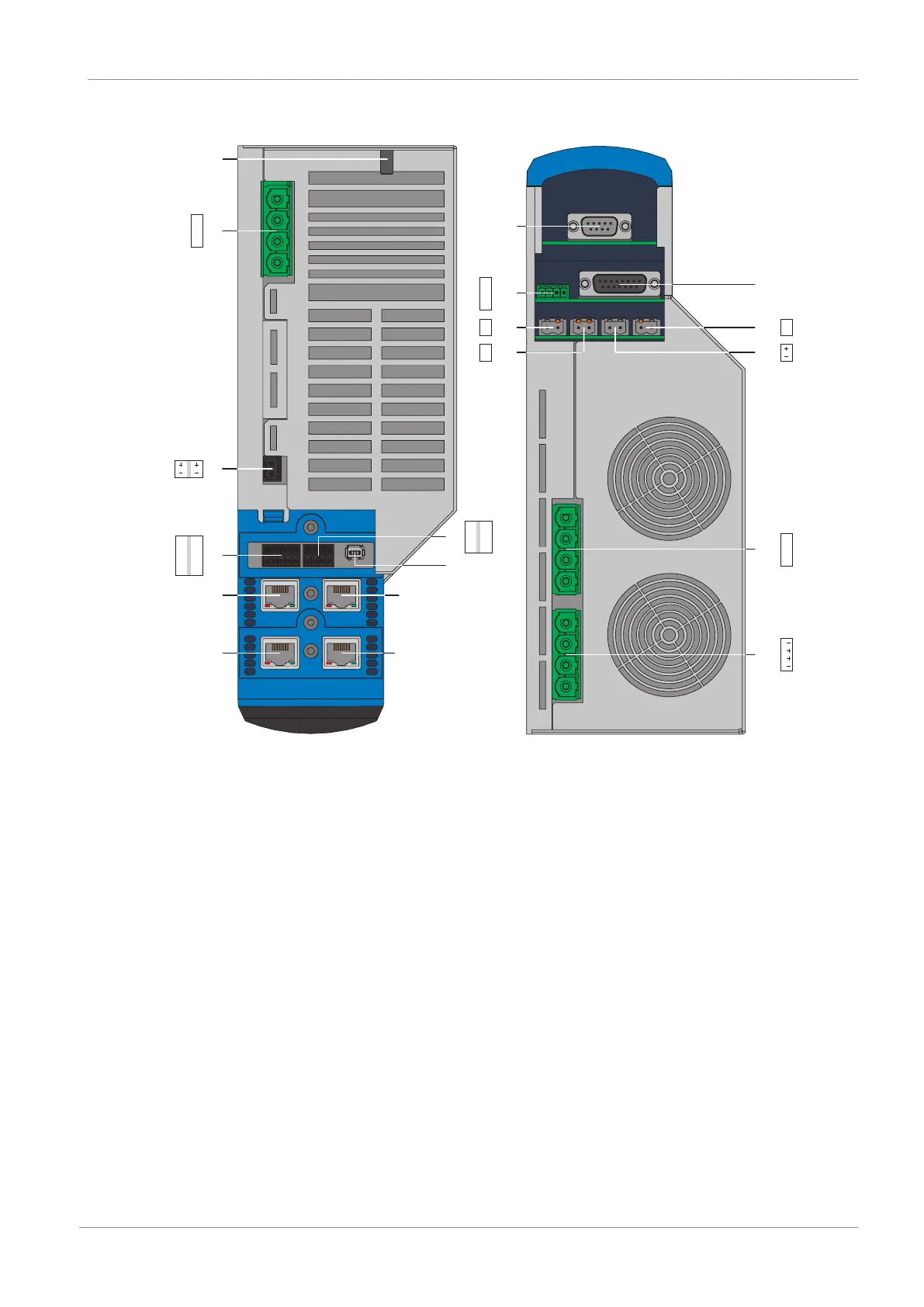

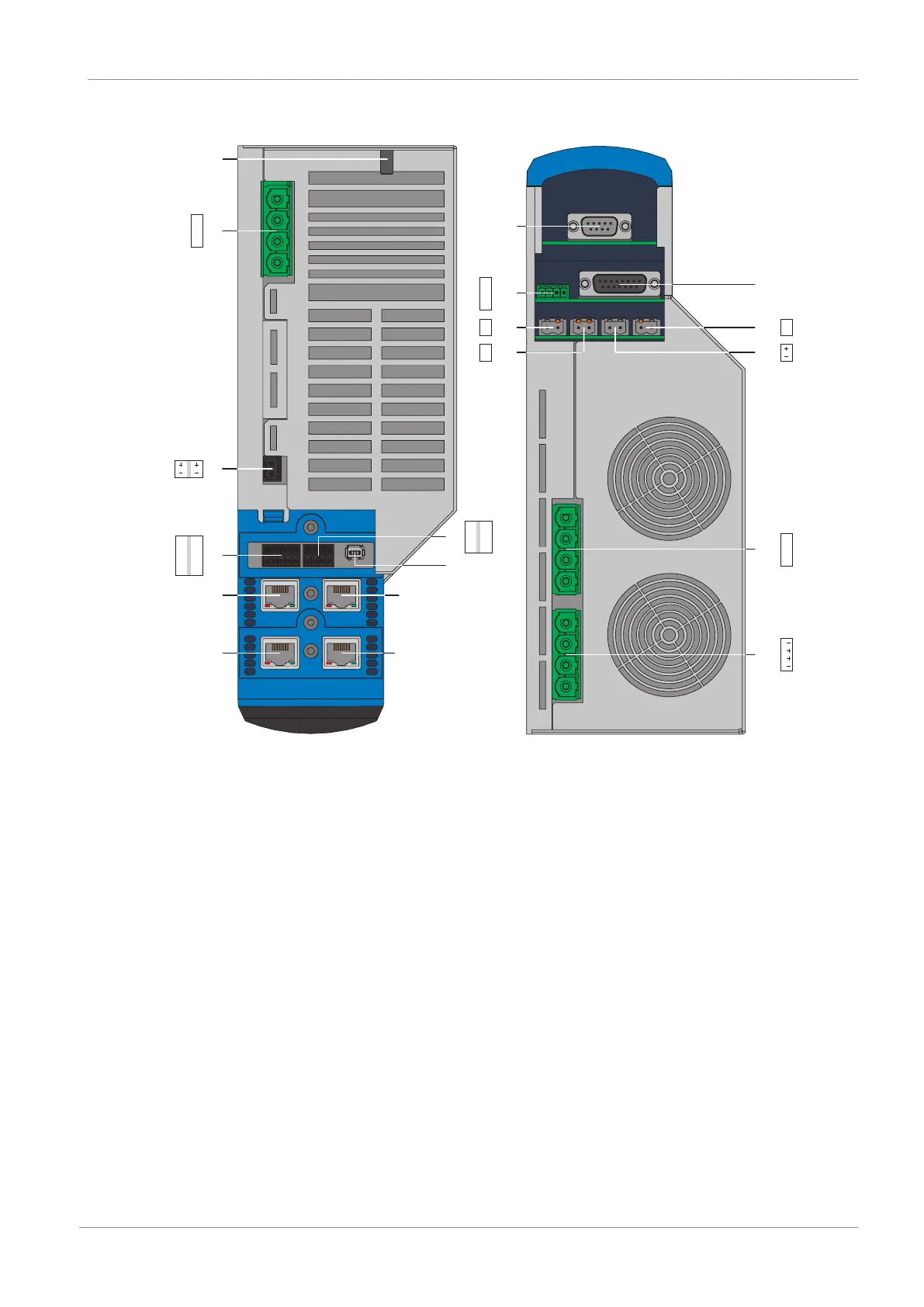

8.4.2.2 Size 2

13

X4

12

X1

4

2

3

1

14

X2

8

7

16

X7

18

PE

V

W

U

X20

19

X30

D

D

R

R

1

2

PE

L2

L3

L1

X10

8

X3B

10

X201

9

X200

7

X3A

11

X120

15

X8

17

X5

6

5

3

X11

4

5

3

4

2

1

X14

10

8

9

7

6

6

X50

8

6

7

5

X15

5

4

2

3

1

4

3

Fig.15: Connection overview of size 2 with SE6 safety module

1 Ground bolt 11

X120: Encoder connection on optional XI6

terminal module (alternatively X120 and

X140: Encoder connections on RI6 terminal

module or IO6 terminal module without

encoder connection)

2 X10: 230/400V

AC

supply 12 X1: Enable and relay 1

3 X11: 24V

DC

supply 13 X4: Encoder

4 X14: SE6 safety technology – Safe inputs 14 X2: Motor temperature sensor

5

X15: SE6 safety technology – Safe outputs

and supply for X50

15 X8: Brake 2 (SBC+/−)

6

X50: SE6 safety technology – Plausibility

encoder

16 X5: Brake 1 (BD1/BD2)

7 X3A: PC, IGB 17 X7: Supply for brake(s)

8 X3B: PC, IGB 18 X20: Motor

9

X200: EtherCAT on the optional EC6

communication module

(alternatively CANopen on CA6

communication module or

PROFINET on PN6 communication module)

19 X30: Quick DC-Link, braking resistor

10

X201: EtherCAT on the optional EC6

communication module

(alternatively PROFINET on PN6

communication module)

Loading...

Loading...