III-68

Inspection and Maintenance-

without gauges

• Discussion of Inspection & Maintenance Survey Results

• Visual Inspection - System Off

• Electrical System Inspection

• Performance Inspection - Engine Running

• Heater System Inspection

• Preventive Maintenance Worksheet

• Chapter Review

Discussion of Inspection & Maintenance Survey Results

There are three reasons for regular inspection and maintenance procedures:

1. They save money in the long run by reducing down time and often

prevent more costly repairs.

2. They help to insure driver comfort and safety.

3. They add to your store of knowledge about these systems and main-

tain your level of efficiency.

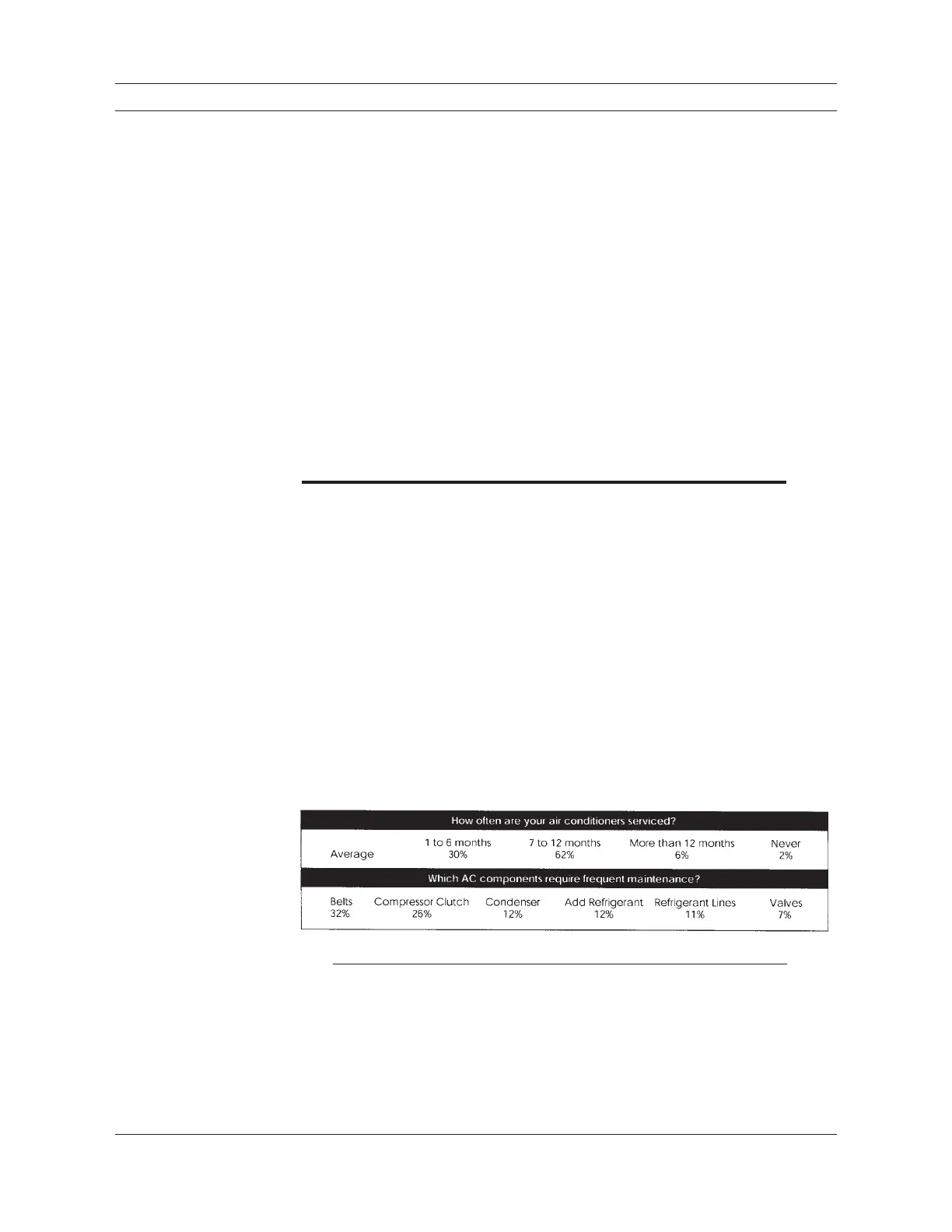

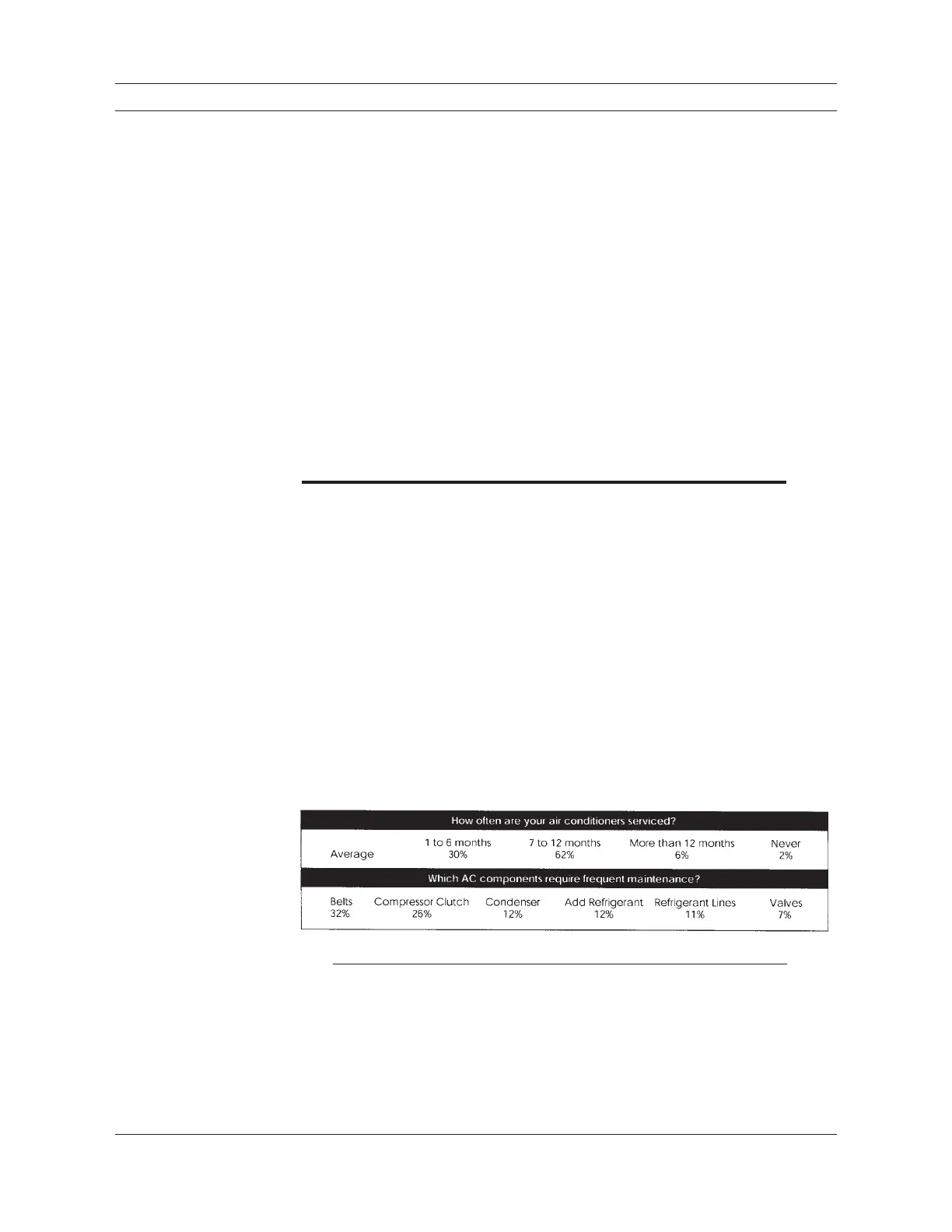

About half of all heavy duty vehicles have air conditioners. Surveys of AC system

owners find that over 30% of the systems are serviced every six months or less, and

another 62% are serviced at least once a year.

The survey also covered how often the different components required maintenance.

Figure 7.1 below shows survey finding percentages. Failure of any of the AC compo

-

nents listed in the survey could cause a system to malfunction or stop cooling.

INSPECTION & MAINTENANCE SURVEY

Note: The above survey results may not apply to your situation. Actual

operating conditions for the vehicles you service will determine

or influence maintenance frequency and requirements.

The following inspection procedures should take about 15 to 20 minutes, longer if

corrective steps, part replacement or adding refrigerant is necessary. There is a “Pre-

ventive Maintenance Worksheet” you may use at the end of this chapter, Figure 7-9

C

l

i

c

k

o

n

a

n

y

o

f

t

h

e

s

e

s

u

b

-

j

e

c

t

h

e

a

d

i

n

g

s

t

o

g

o

d

i

r

e

c

t

l

y

t

o

t

h

e

p

a

g

e

Figure 7-1

This chart shows mainte-

nance frequency, lists key

parts and how often they

require maintenance.

Loading...

Loading...