IV-134

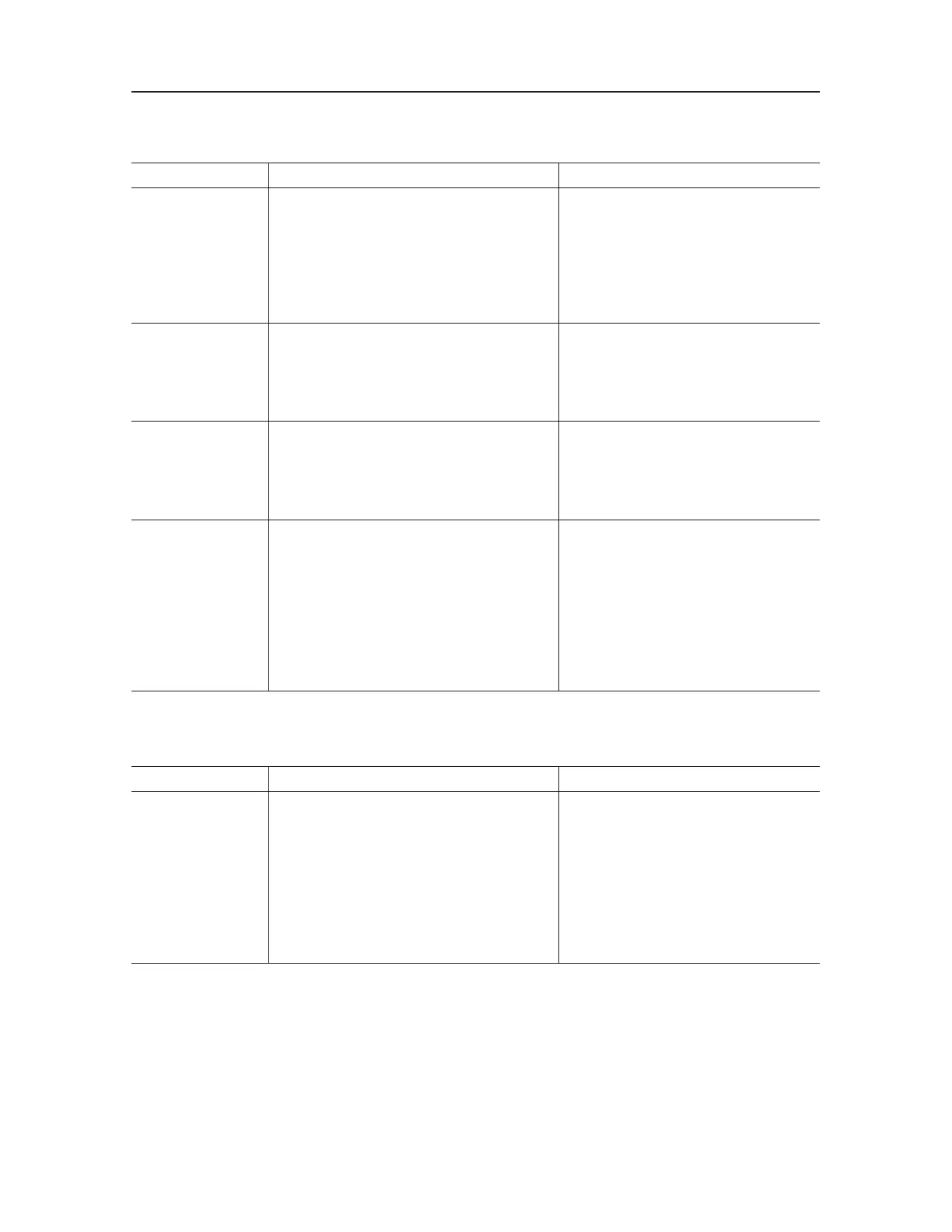

HYDRAULIC UNITSTRAVEL MOTOR

TROUBLESHOOTING

Hydraulic motor

Symptoms Major causes Remedies

Motor fails to start • All the devices other than the motor and the

reduction gears are not working correctly

• Pressure oil is not flowing properly due to

abnormal wear of the motor·s sliding part

• Motor is faulty, as its main components are

damaged

• Check whether the specified pressure

is generated in the inlet port, and then

check and repair each device.

• Replace the abnormally worn out

part(s).

• Replace the damaged part(s).

Rated speed cannot

be obtained

• Specified volume of flow is not supplied to

the motor due to the faulty oil pump

• Motor volume efficiency becomes low

• Check whether the specified pressure

is generated in the inlet port, and then

check and repair each device.

• Check if there is abnormal wear on the

sliding part; if so, repair or replace it.

Rotational fluctua-

tions are large

• High-pressure oil is leaking from the drain

port, because the motor·s sliding part is

worn out

• Bearing is worn out

• Replace the abnormally worn part, if

any.

• Replace the abnormally worn part, if

any.

Oil leak • Oil leak due to breakage of oil seal and O-

ring

• Oil seal is broken by the internal pressure

generated in the motor case due to the ab-

normal wear of the sliding part of the mo-

tor

• Pressure increase in the drain piping caused

by the clogging of foreign matter resulted

in breakage of oil seal

• Replace the oil seal and O-ring.

• Repair the motor and replace the oil

seal.

• Clean the clogging in the drain piping

and replace the oil seal.

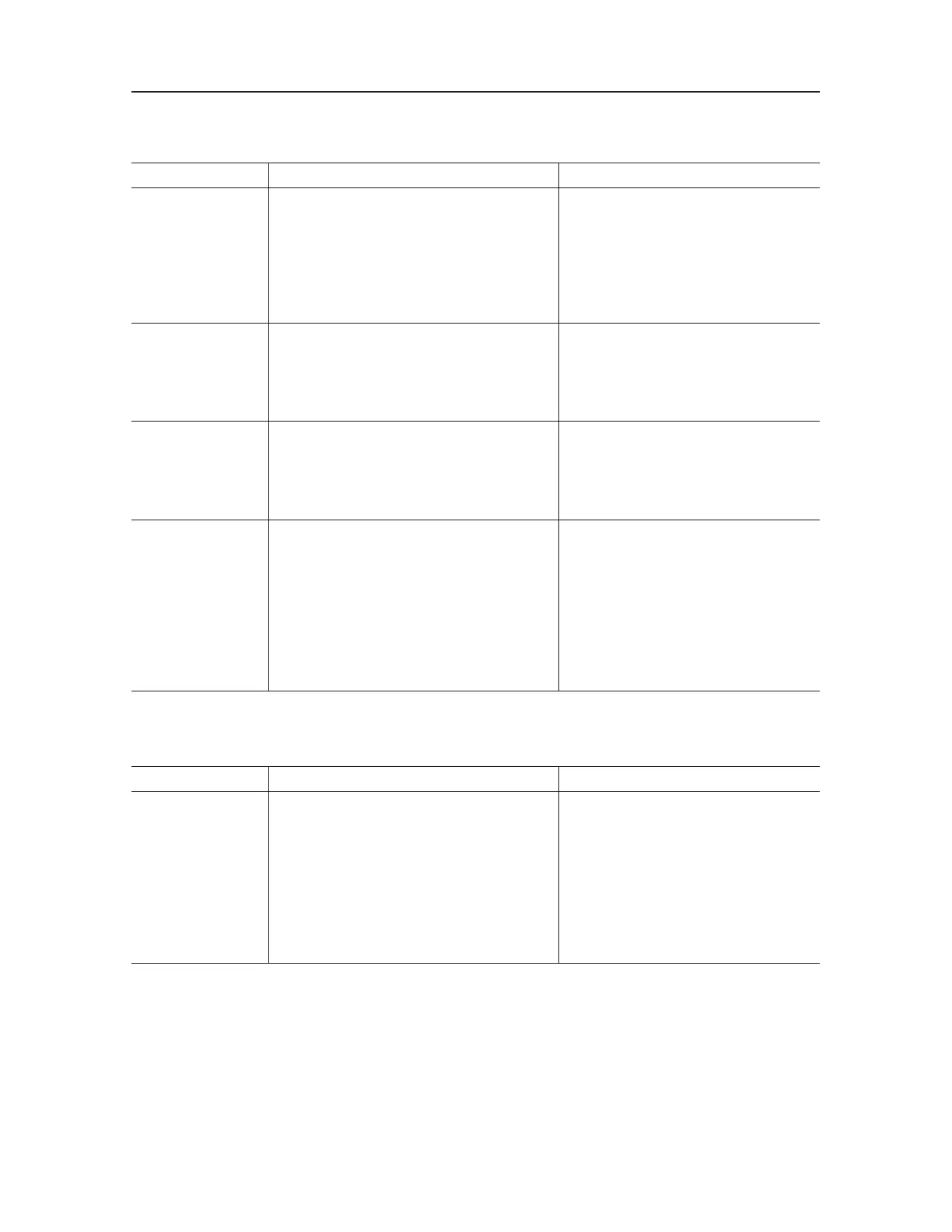

2nd speed control

Symptoms Major causes Remedies

Straight-ahead trav-

eling level is low,

switching to 2nd

speed travel is dis-

abled

Spool cannot be switched

• Foreign matter is caught

• Spring is missing

• Spring is damaged

• Oil leak due to the abnormal wear of the

2nd speed control piston

• 2nd speed control piston is missing

• Ball is abnormally worn out

• Remove foreign matter and correct or

replace the faulty part(s).

• Install the spring.

• Replace the spring.

• Replace the 2nd speed control piston.

• Install the 2nd speed control piston.

• Replace the ball.

Loading...

Loading...