IV-104

HYDRAULIC UNITSCYLINDERS

INSPECTION AND ADJUSTMENT

Inspection after Disassembly

Clean each part thoroughly with cleaning oil, then

carry out the following checks. When a cylinder has

been disassembled, replace all the seals with new

ones.

Piston Rod

• Replace the rod if there are cracks.

• If the threads are damaged, repair them or replace

it.

• If the plating layer of the plated portion is broken,

rusted or scratched, replace it.

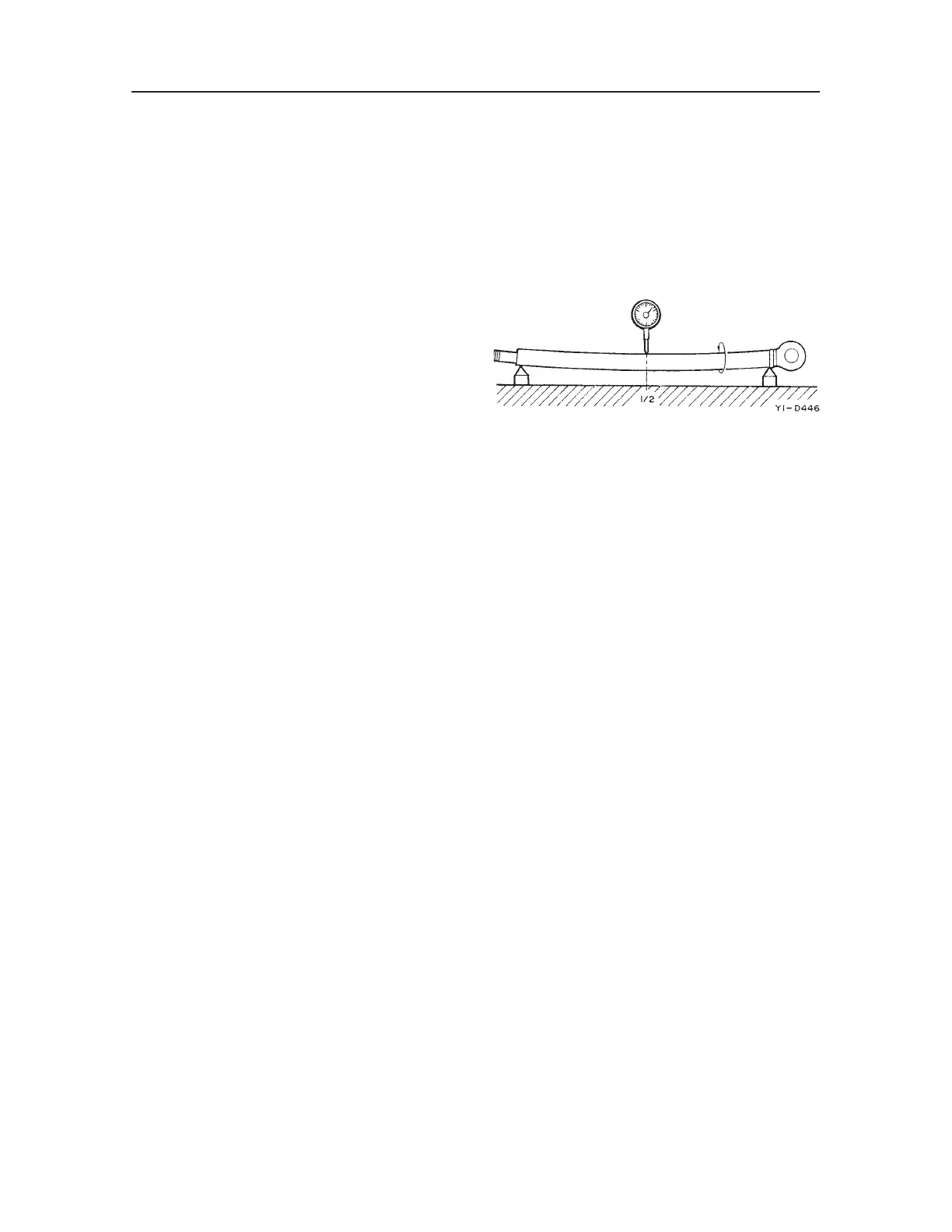

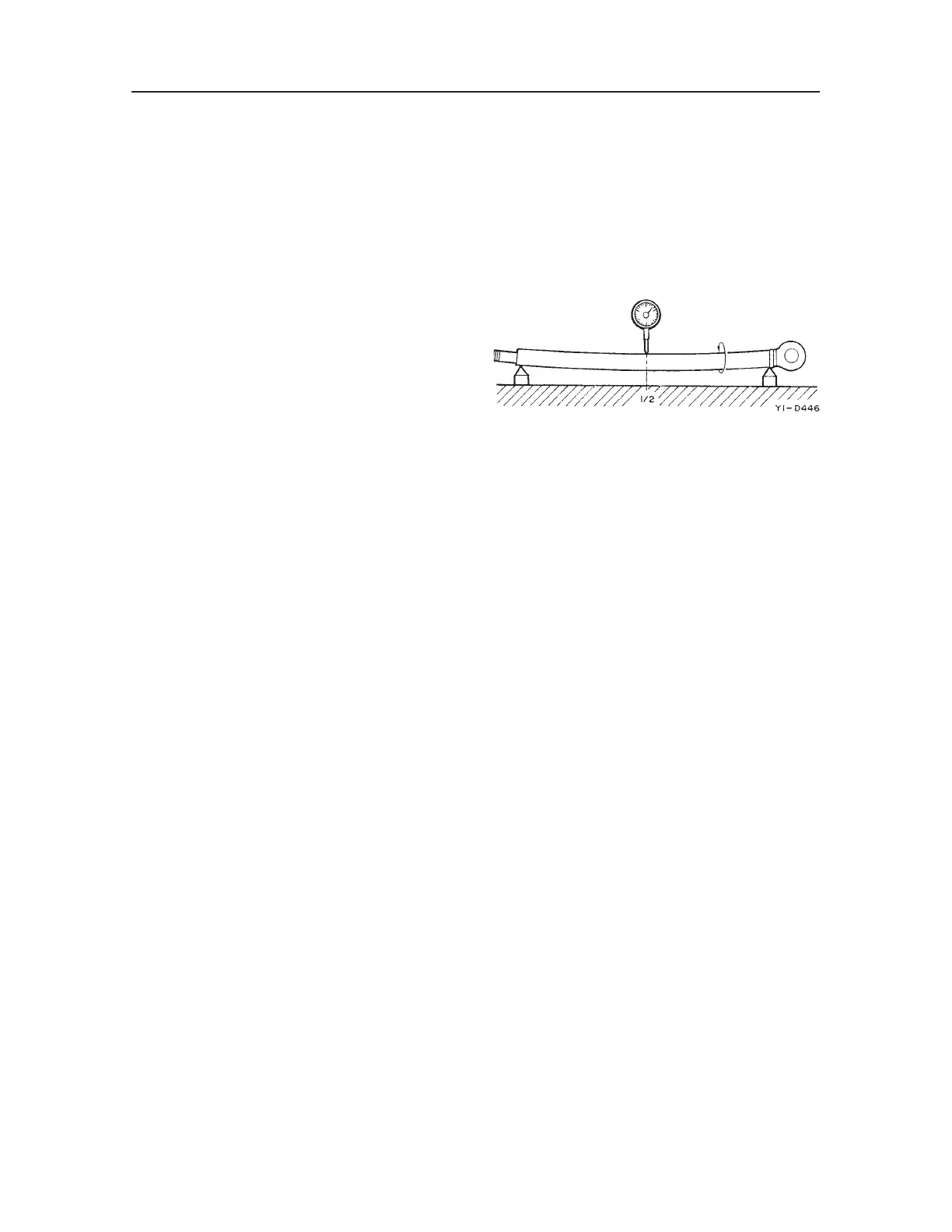

• If the rod is bent more than the limit of 1 mm in

1 m, replace it. (Measure by the method shown in

the figure at right.

If the bending of the rod is within the above limit,

yet is bent a lot in a small distance so that it won·t

move smoothly, replace the rod if it makes a

squeaking sound in the operation test after reas-

sembly or if it catches during movement.

• If the inner diameter of the clevis bushing is worn,

replace the bushing.

Tube

• If there are cracks in the welded portion, replace

it.

• Replace the tube if the inside surface is scratched

or if it leaks hydraulic oil.

• If the inner diameter of the clevis bushing is worn,

replace the bushing.

Rod Cover

• If the bushing inner diameter is worn and the

clearance with the piston rod is greater than 0.25

mm, replace the bushing.

• If the inside surface of the bushing is scratched,

and the scratches are deeper than the depth of the

coating layer, replace the bushing.

Measuring the Bend

a. Support the portion of the rod with the same di-

ameter at both ends on V-blocks.

b. Set a dial gauge at the center between the two

blocks.

c. Rotate the rod and take a reading of the maximum

and minimum runout indicated by the dial gauge.

Loading...

Loading...