IV-62

HYDRAULIC UNITS

CONTROL VALVE (HIGH FLOW)

Adjusting the Relief Valve Pressure

• Engine : Rated R.P.M.

• Hydraulic Oil Temp. : 50~60°C

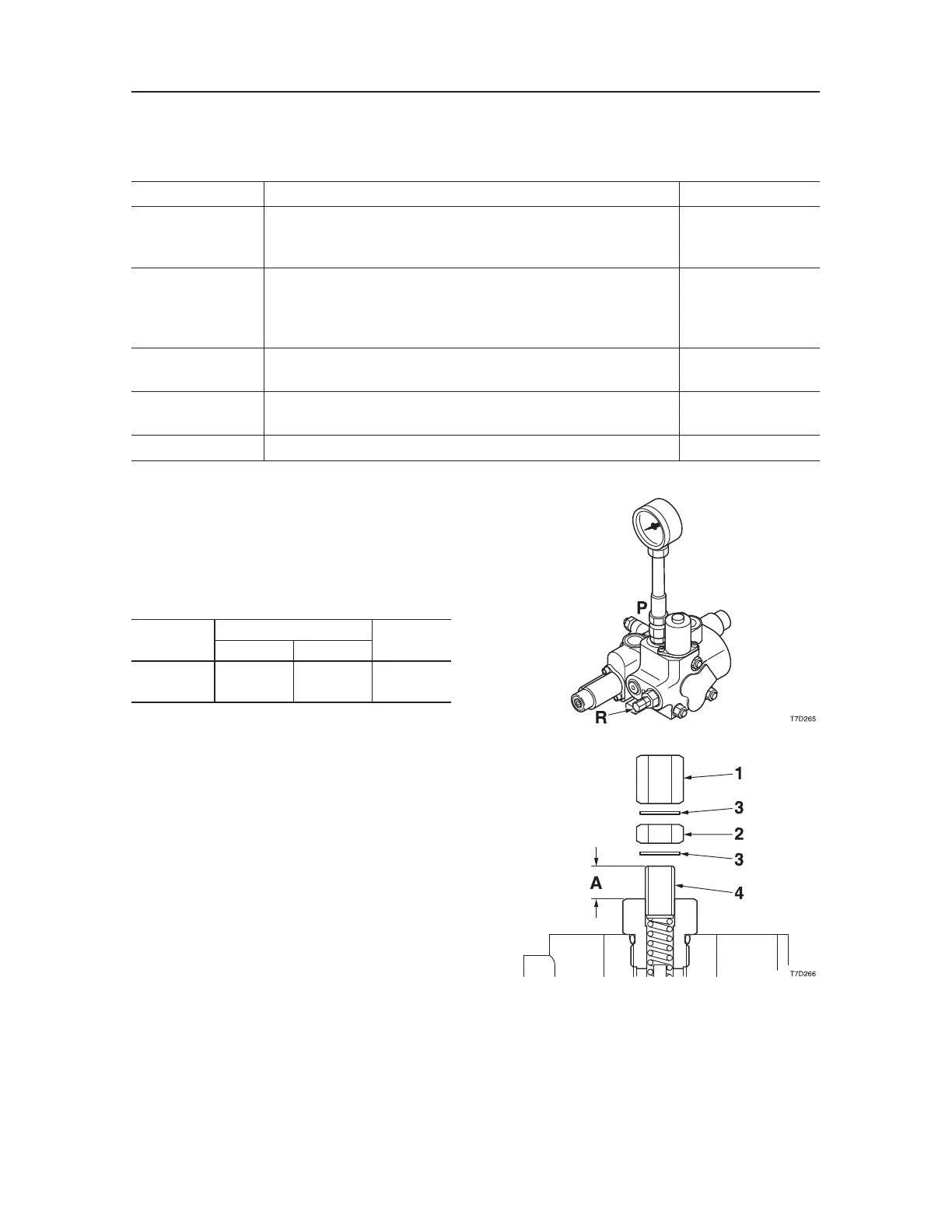

• Mount the pressure gauge on the pressure detec

-

tion port, operate the desired hydraulic circuit and

measure the relief pressure.

Circuit

Pressure Detection Port

Relief

Valve

Port Position

Size

Auxiliary

(High Flow)

P G 1/2 R

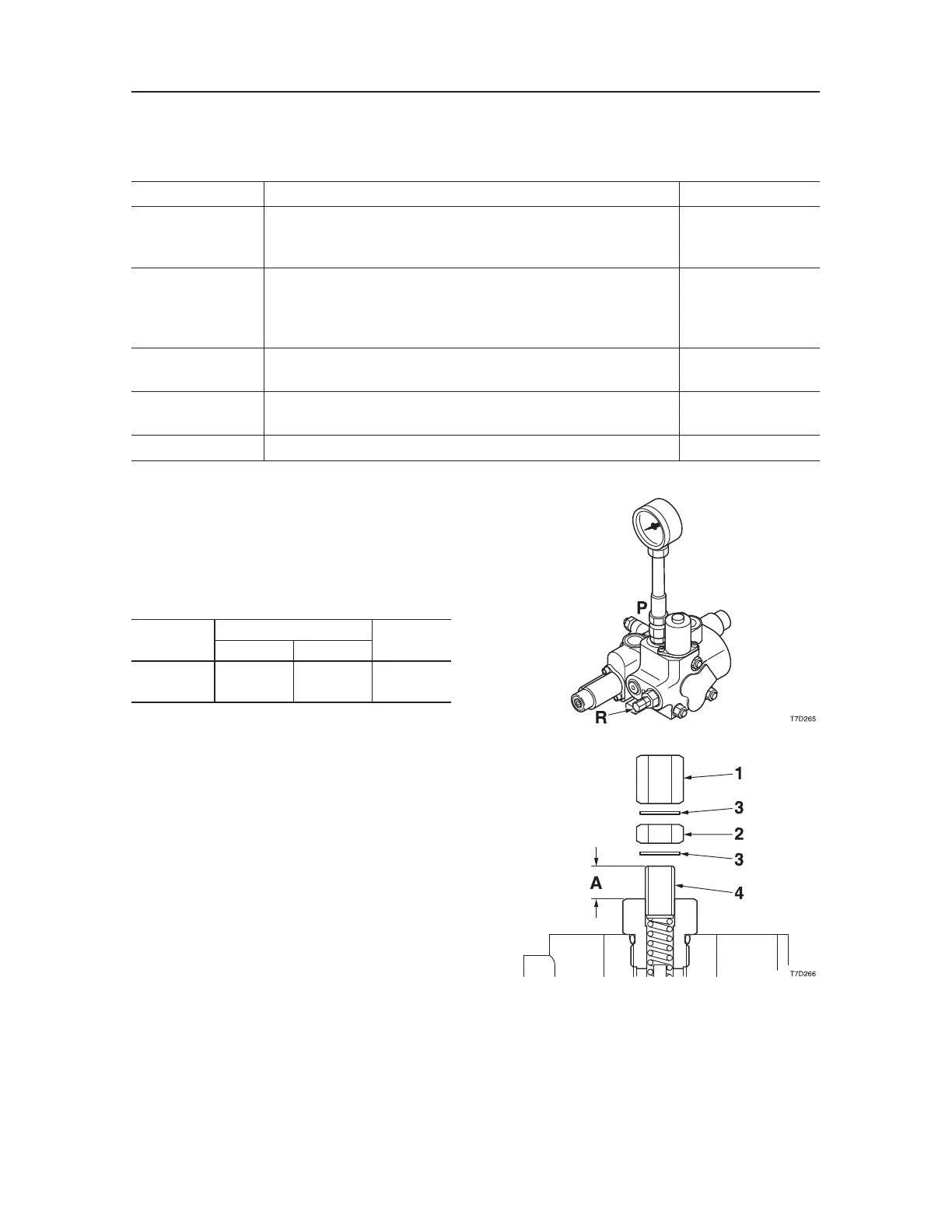

1. Remove the cap screw (1), shim (3), lock nut (2)

and shim (3) in this order.

• The shims must be replaced for every adjust

-

ment.

2. Make sure to record the dimension of the section

A of the setscrew (4).

3. Adjust the set value by turning the setscrew (4).

Turning clockwise .................

raises the set pres-

sure.

Turning counterclockwise .....

lowers the set

pressure.

• Change of pressure per turn: 9 MPa

4. In order to keep the setting screw from turning

after pressure has been adjusted, tighten the

locknut while at the same time holding the set-

ting screw firmly in place.

5. Operate the relief valve once more to confirm

that the pressure that has been set it stabilized.

INSPECTION AND ADJUSTMENT

Checking the Parts

Parts Judgment Criteria Treatment

Solenoid coil • When the solenoid is burned, short-circuited, or has a wire

break

• Wiring short-circuit or wire break

• Replace

• Replace

Body • Scratches, rust, or corrosion at the sliding parts with the spool

• Scratches, rust, or corrosion of the seal part in contact with the

O-ring

• Other damage considered to impair the normal functions

• Replace

• Replace

• Replace

Spool, plunger • Damage on the outer circumference which catches a fingernail

• No smooth movement

• Replace

• Adjust or replace

Spring • Rust, corrosion, deformation, breakage, or other notable dam-

age

• Replace

O-Ring

±±

• Replace

Loading...

Loading...