IV-53

HYDRAULIC UNITSCONTROL VALVE

Adjusting the Main Relief Valve Pressure

1. Install a pressure gauge in the following pres

-

sure sensor port.

• Control valve pressure sensor port.

“II. Specifications, Standards for Judg-

ing Performance”

2. Run the pump at the rated speed.

3. Operate the control valve·s cylinder spool over

its full stroke and read the value indicated by the

pressure gauge.

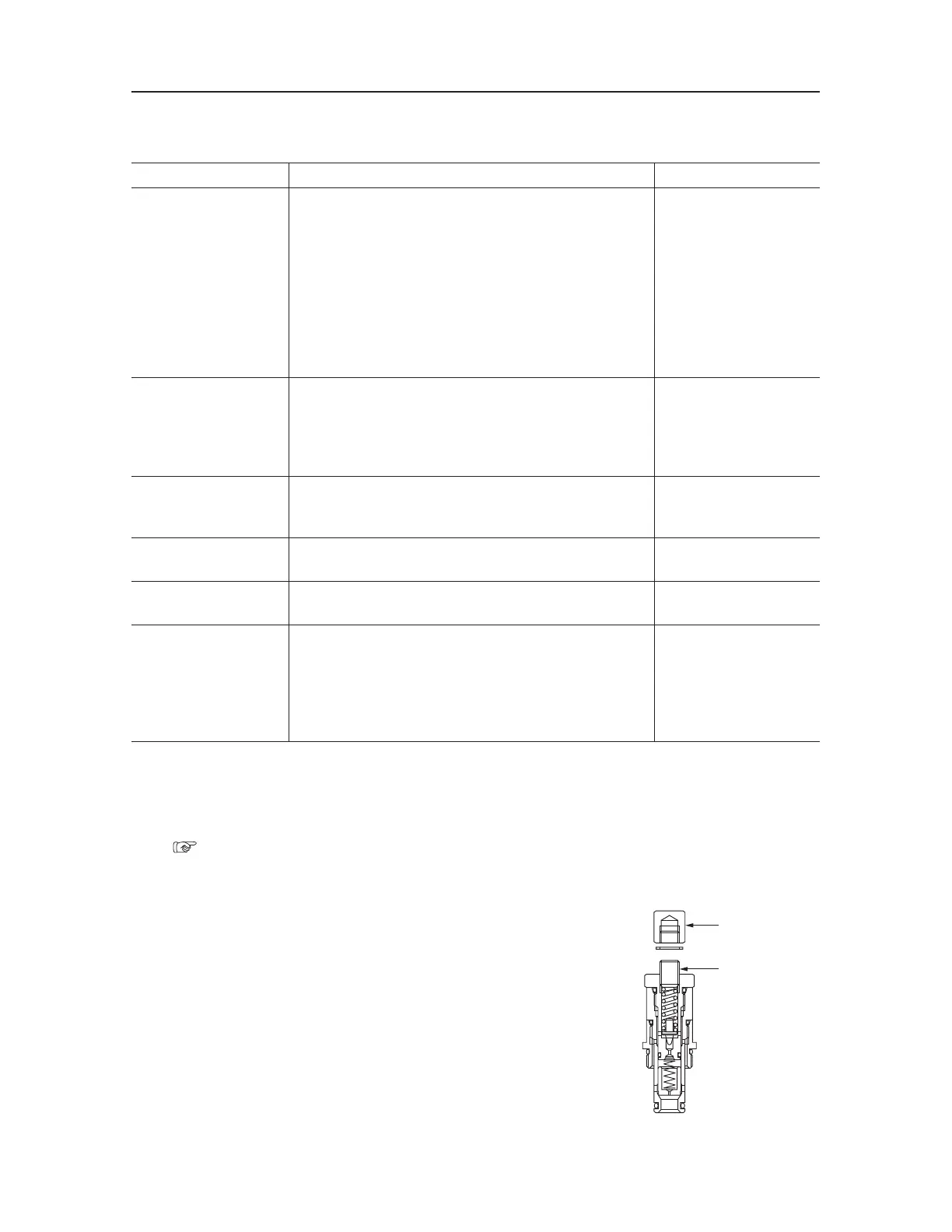

4. Turn the set screw (1) while watching the pres

-

sure gauge to adjust.

Turning it to the right increases the set pres

-

sure.

Turning it to the left decreases the set pressure.

5. After completing the pressure adjustment, tight

-

en the lock nut (2) while holding the set screw

(1) so it won·t turn.

Operate the relief valve again and check if the

pressure is stabilized.

INSPECTION AND ADJUSTMENT

Checking the Parts

Parts Judgment Criteria Treatment

Housing,

Section Body

• Scratches, rust, corrosion of the portion which slides

against the spool.

• Scratches, rust, corrosion of the seal pocket portion of

the part that enters the spool.

• Scratches, rust, corrosion of the port seal portion which

is in contact with the O-ring.

• Scratches, rust, corrosion of the seal portion of the relief

valve, etc.

• Other damage which could be a hindrance to correct

function.

• Replace

• Replace

• Replace

• Replace

• Replace

Spool • Scratch marks like being clawed around the outer cir-

cumference sliding portion.

• Scratches on the portion that slides against the seals on

both ends.

• Spool not operating smoothly.

• Replace

• Replace

• Repair or replace.

Load Check Valve • Imperfect sealing due to damage to the valve or spring.

• Does not catch, but operates lightly when inserted in the

section body and operated.

• Repair or replace.

• Normal

Around Springs • Rust, corrosion, deformation, breakage or other marked

damage to the spring, holder or cover.

• Replace

Around Spool Seal • Oil leaking to the outside.

• Rust, corrosion or deformation of the seal holder.

• Repair or replace.

• Repair or replace.

Main Relief Valve,

Port Relief Valve,

Anti-Cavitation Valve

• External rust, damage.

• Damage to valve seat contact surface.

• Damage to poppet contact surface.

• Abnormality in the spring.

• O-rings, backup rings, seals

• Replace

• Replace

• Replace

• Replace

• As a rule, all these

should be replaced.

Loading...

Loading...