III-19

MACHINE CONFIGURATION

TRAVEL SYSTEM

DISASSEMBLY AND ASSEMBLY

Removing the Steel Track

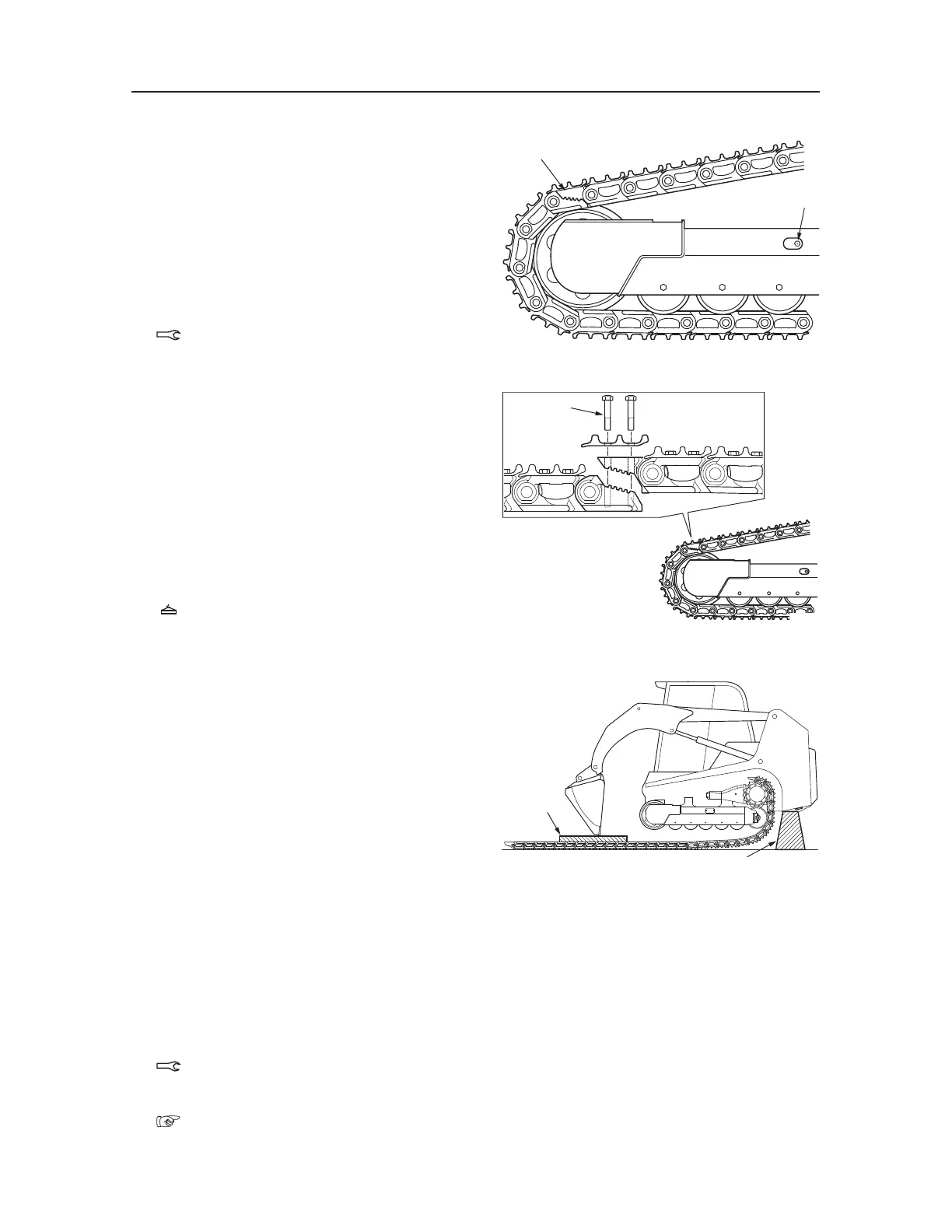

Stop the machine so that the master links are

positioned at the top of the idler.

1. Loosen the track tension.

When loosening the grease discharge valve (1),

turn it slowly. Do not loosen it beyond the point

where grease starts to ooze out. If it is difficult

for the grease to come out, move the machine

forward and in reverse.

Grease discharge valve: 59 N·m

2. Remove the master bolts (2) and disconnect the

master links (3).

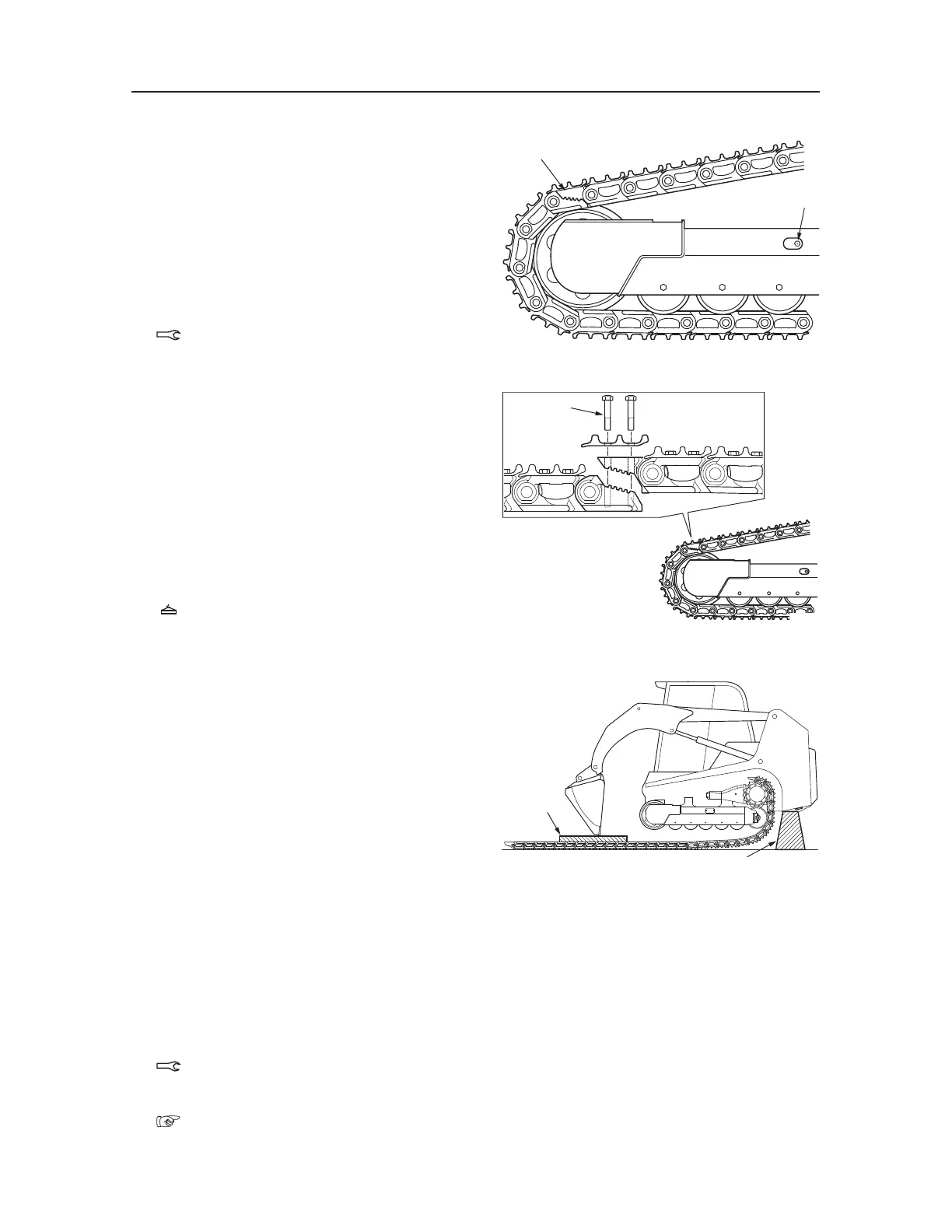

3. Place the wooden blocks (4) with a height of 20

cm under the cutting edge of the bucket and tilt

the bucket forward and lower the lift arms to

raise the machine front.

4. Suspend the machine rear and place a block (5)

under the machine rear.

5. Rotate the travel motor slowly in the reverse

direction to remove the track

Track: 401 kg

Installing the Steel Track

1. Place the wooden blocks (3) with a height of 20

cm under the cutting edge of the bucket and tilt

the bucket forward and lower the lift arms to

raise the machine front.

2. Suspend the machine rear and place a block (4)

under the machine rear.

3. Position the track beneath the frame.

• Be careful not to mistake the installation di-

rection of the track.

4. Engage the links in the sprocket, then rotate the

travel motor slowly in the forward direction to

wrap the track around the frame.

5. When the master link reachs a point just to the

top of the idler, stop rotating the sprocket and

lower the machine to the ground.

6. Connect the master links and install the shoe

plate and the master bolts.

Master bolt: 225±10 N·m

7. Adjust the track tension.

“II. Specifications, Standards for Judging

Performance”

Loading...

Loading...