IV-135

HYDRAULIC UNITSTRAVEL MOTOR

Parking brake

Symptoms Major causes Remedies

Braking force is

insufficient or not

evenly applied

• The total thickness of three friction discs

and four center discs is 13.5 mm or less

• Disc surface is faulty

• Spring is damaged

• Bolt for manual releasing is being fitted

• Replace the discs.

• Repair or replace.

• Replace the spring.

• Remove the bolt for manual release, and

fit the plug.

Abnormal heat gen-

eration due to brake

drag

Release of braking is faulty

• Oil leak due to O-ring breakage

• Orifice is clogged

• Pilot pressure for the releasing is not

working

• Replace the O-ring.

• Clean the orifice.

• Check whether the specified pressure

is generated in the pilot port, and then

check and repair each device.

Mechanical releasing of the brake

WARNING

While the brake is mechanically released, the

piston motor loses its mechanical braking ca-

pability. The mechanical braking capability of

the vehicle must be maintained by means of

a vehicle brake, or for stationary equipment,

must be maintained by means of an equipment

brake in order to avert any danger to life and

limb.

In case of lacking brake-bleeding pressure it may

be necessary to move a stationary machine. For this

purpose it is possible to release the brake mechani-

cally.

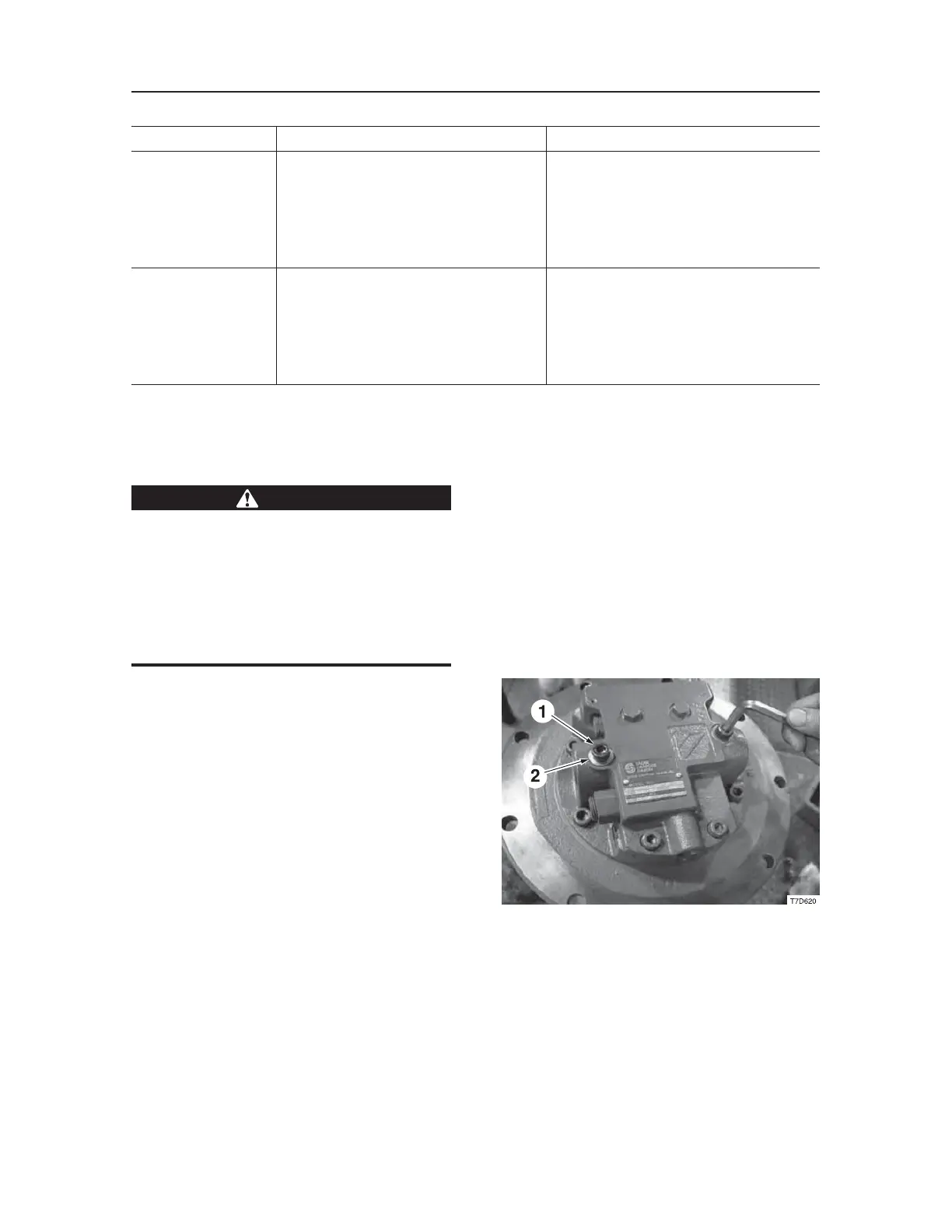

For mechanical releasing, prepare two socket head

screws 1 of M10×90 and two hard washers (2)

of M10. For brake releasing, the two socket head

screws must be turned uniformly in a clockwise

direction (alternately 1/2 rotation) in order to avoid

cocking of the piston.

Turning the screws pulls the brake piston against the

effect of the brake spring and thus the braking effect

is neutralized.

Turn the screws until they come into a contact with

the brake piston and continue until the piston comes

against the stop. The brake has been released.

Loading...

Loading...