IV-94

HYDRAULIC UNITSCYLINDERS

DISASSEMBLY AND ASSEMBLY

Special Tools

See the table of special tools at the back of this sec-

tion for the jigs and tools used for disassembly and

assembly.

General Cautions

• Carry out disassembly and assembly in a clean

place and place the disassembled parts in a place

where they will be kept clean at all times.

• Before disassembly, clean the outside surface of

the cylinder thoroughly.

• In the disassembly and assembly operations, be

careful not to scratch any part. Take particular

caution with the sliding surfaces of parts.

• Clean all disassembled parts thoroughly with

cleaning oil.

• Replace all seals with new parts.

• Apply a thin coating of hydraulic oil to seals be

-

fore fitting them in place.

• After fitting, make sure the O-rings are not twist

-

ed.

• Apply clean hydraulic oil to each sliding portion

before assembling them.

In this manual, the procedure for the arm cylinder

is described. When necessary, the points which are

different in other cylinders are mentioned.

Disassembly

Cylinder Assembly

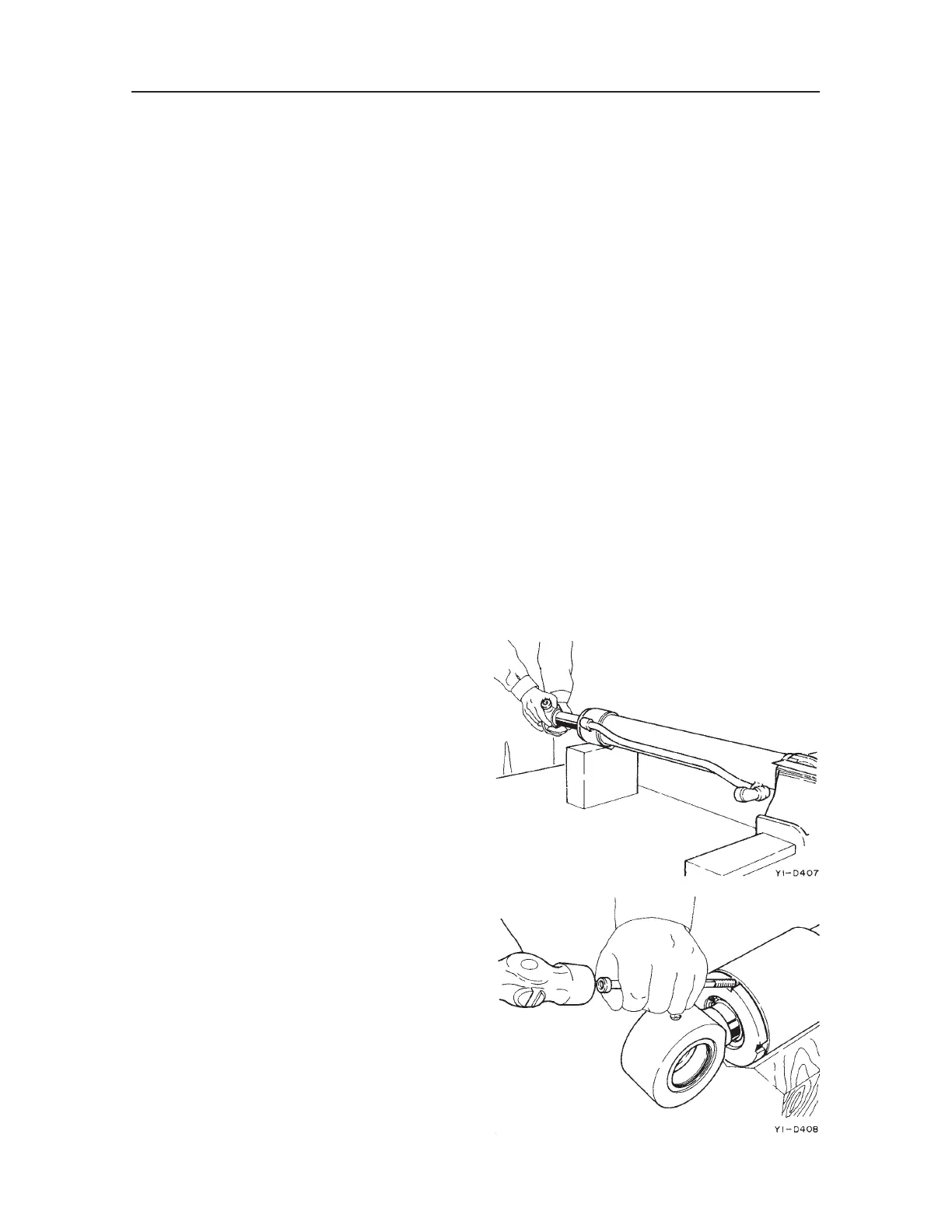

1. Fasten the clevis of the tube in a vice and place

the other end on a support black made of wood

to fasten the cylinder in a horizontal condition.

2. Drain out hydraulic oil remaining in the cylin-

der.

• Move the piston rod gently to prevent the hy

-

draulic oil from spraying out and scattering

all over.

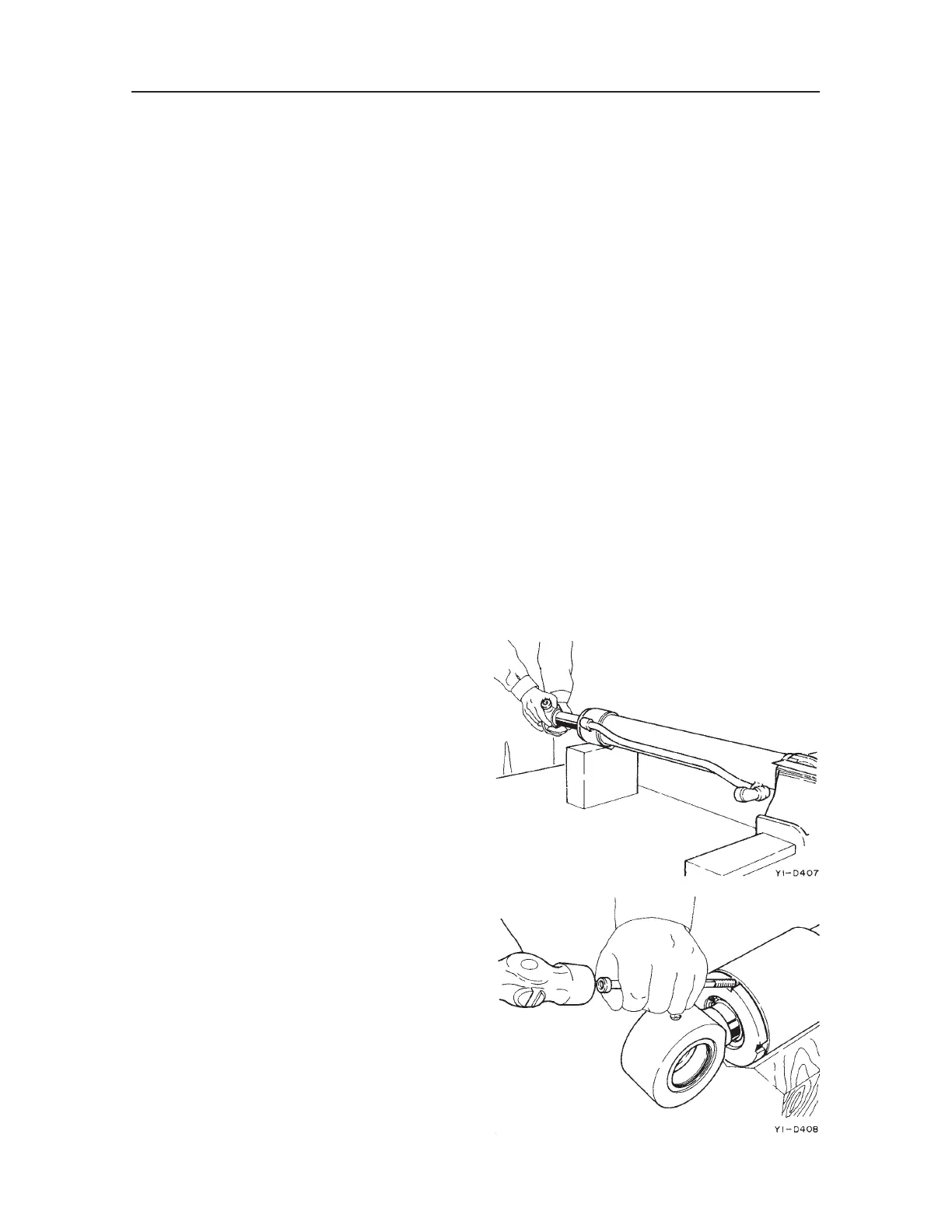

3. Free the locked portion of the rod cover.

• Since the lock is integrated with the cylinder

tube, be careful not to bend it or to scratch it

when the lock is being freed.

Loading...

Loading...