IV-133

HYDRAULIC UNITSTRAVEL MOTOR

INSPECTION AND ADJUSTMENT

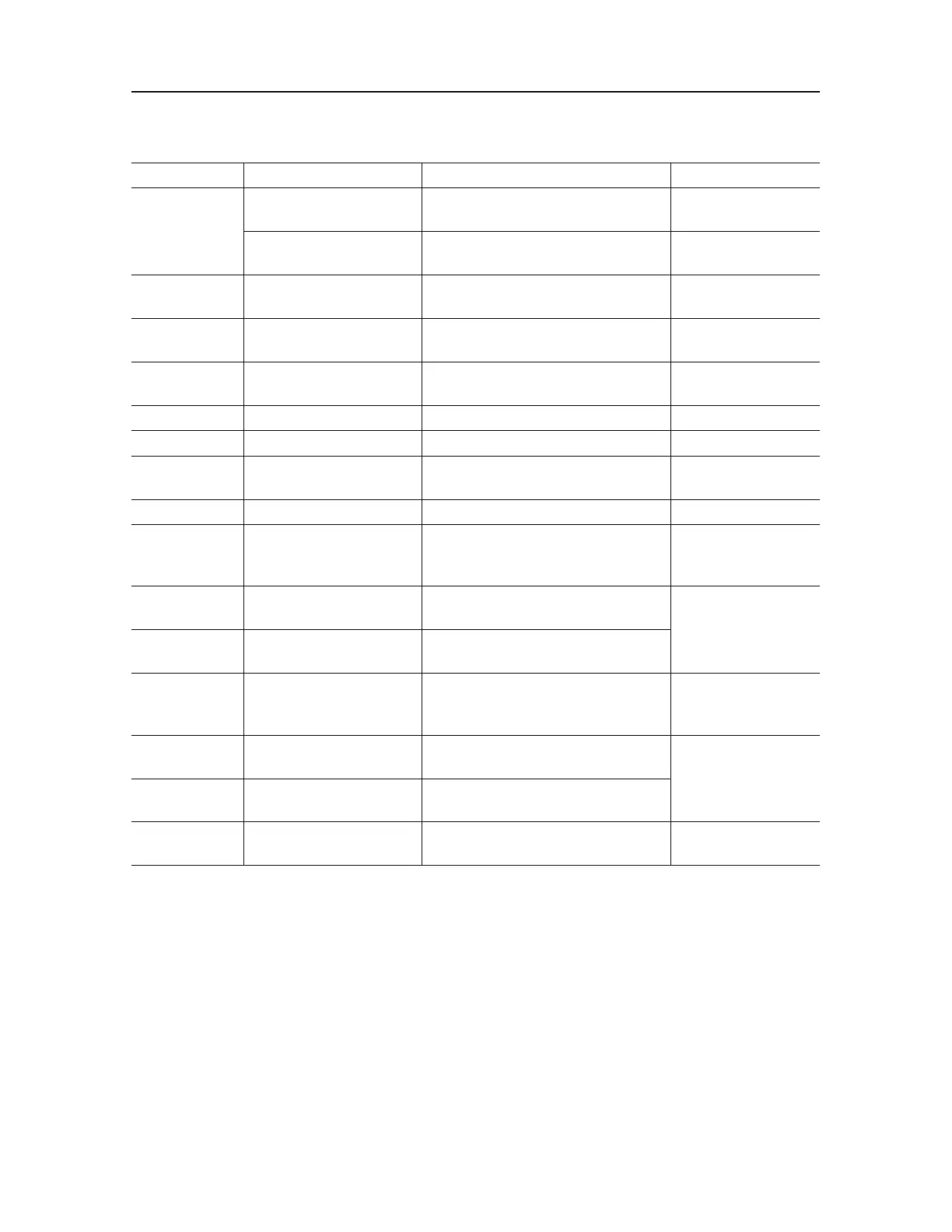

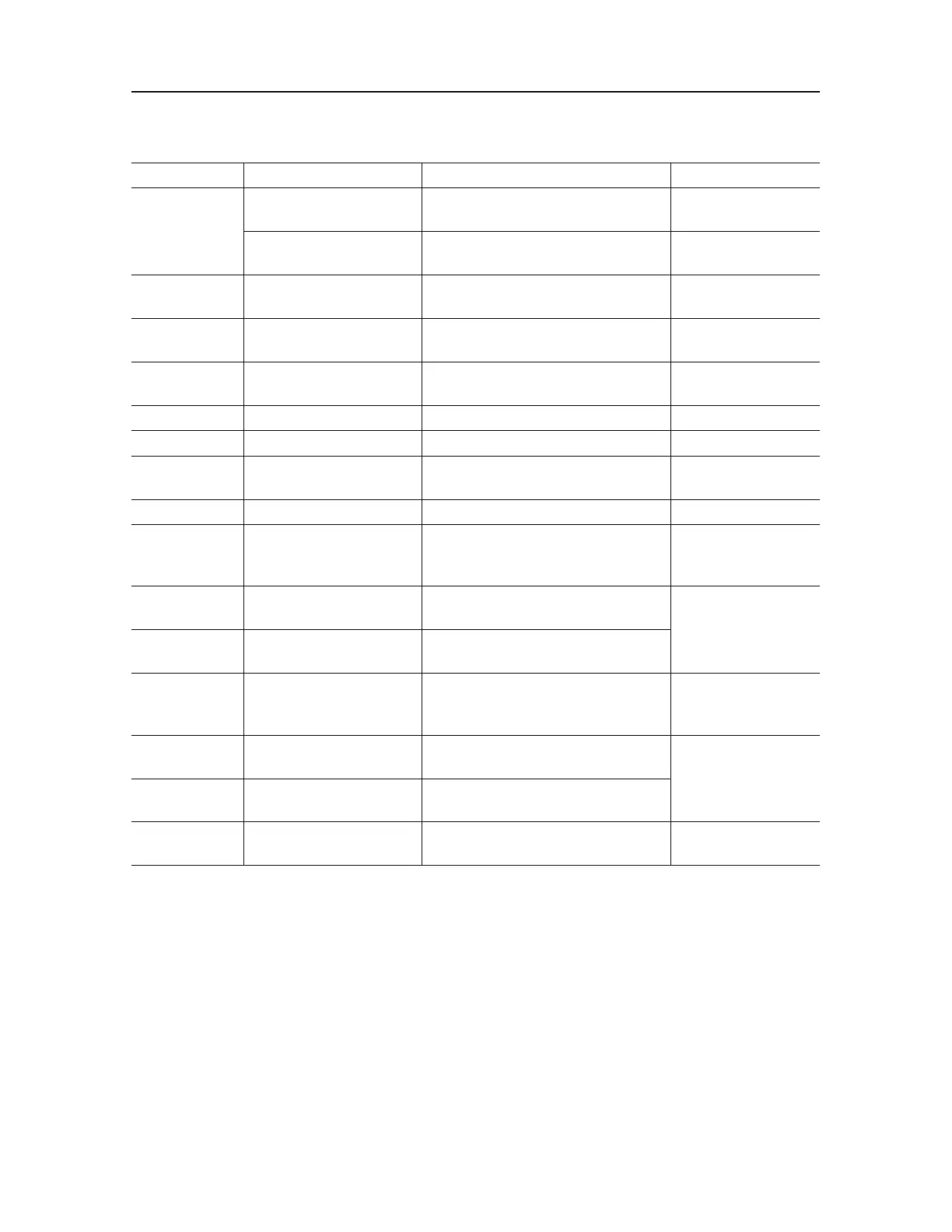

Use Limit for Parts

Part Location Criteria Action

Planet gear Gear tooth surface No abnormal scratches, wear or flak-

ing on the tooth surface

Replace

Rolling surface of the

needle bearing

No abnormal scratches, wear or flak-

ing on the rolling surface

Replace

Needle bearing Needle bearing surface No abnormal scratches, wear or flak-

ing on the surface

Replace

Housing, sun

gear, drive gear

Gear tooth surface No abnormal scratches, wear or flak-

ing on the tooth surface

Replace

Thrust plate Sliding surface No abnormal scratches, wear or flak-

ing on the surface

Replace

O-ring — — Replace

Shaft Oil seal surface No scratches or wear Replace

Ball bearing Sliding surface No abnormal scratches, wear or flak-

ing on the ball or race

Replace

Oil seal — — Replace

Swash plate Surface of the sliding part

with the piston assembly

No abnormal scratches, wear or sei-

zure on the surface

Repair with a lap-

ping tool (#1000) or

replace

Cylinder block Surface of the sliding part

with the valve plate

No abnormal scratches, wear or sei-

zure on the surface

Repair with a lapping

tool (#1000) or replace

the cylinder block and

the piston together

Piston assembly Surface of the sliding part

with the swash plate

No abnormal scratches, wear or sei-

zure on the surface

Valve plate Surface of the sliding part

with the plunger

No abnormal scratches, wear or sei-

zure on the surface

Repair with a lap-

ping tool (#1000) or

replace

Valve body Surface of the sliding part

with the plunger

No abnormal scratches, wear or sei-

zure on the surface

Replace the valve

body and the spool

together

Spool Surface of the sliding part

with the base plate

No abnormal scratches, wear or sei-

zure on the surface

Center disc,

friction disc

Disc thickness Four center discs and three friction

discs are worn to 13.5 mm or less

Replace

Loading...

Loading...