IV-50

HYDRAULIC UNITSCONTROL VALVE

G4D223

DISASSEMBLY AND ASSEMBLY

General Cautions

• Since all parts in control valves are precision

machined, carry out disassembly and assembly

operations in a clean place.

• Before disassembly, clean the outside surfaces

around the valves.

• Clean each of the disassembled parts and apply

clean hydraulic oil to them.

• Apply hydraulic oil to sliding surfaces and apply

a thin coating of grease to seals when assembling

them.

• Replace all seals with new ones each time the

valves are disassembled.

• Spools and section bodies are specially selected

for a precise fit. Therefore, if any damage is found

in either of these parts, replace the section assem-

bly as a unit.

• Be sure to number each section and spool to avoid

mistakes during assembly.

Following is an explanation of the control valve dis-

assembly procedure.

Follow the procedure used to disassemble the con-

trol valve in reverse order when reassembling it.

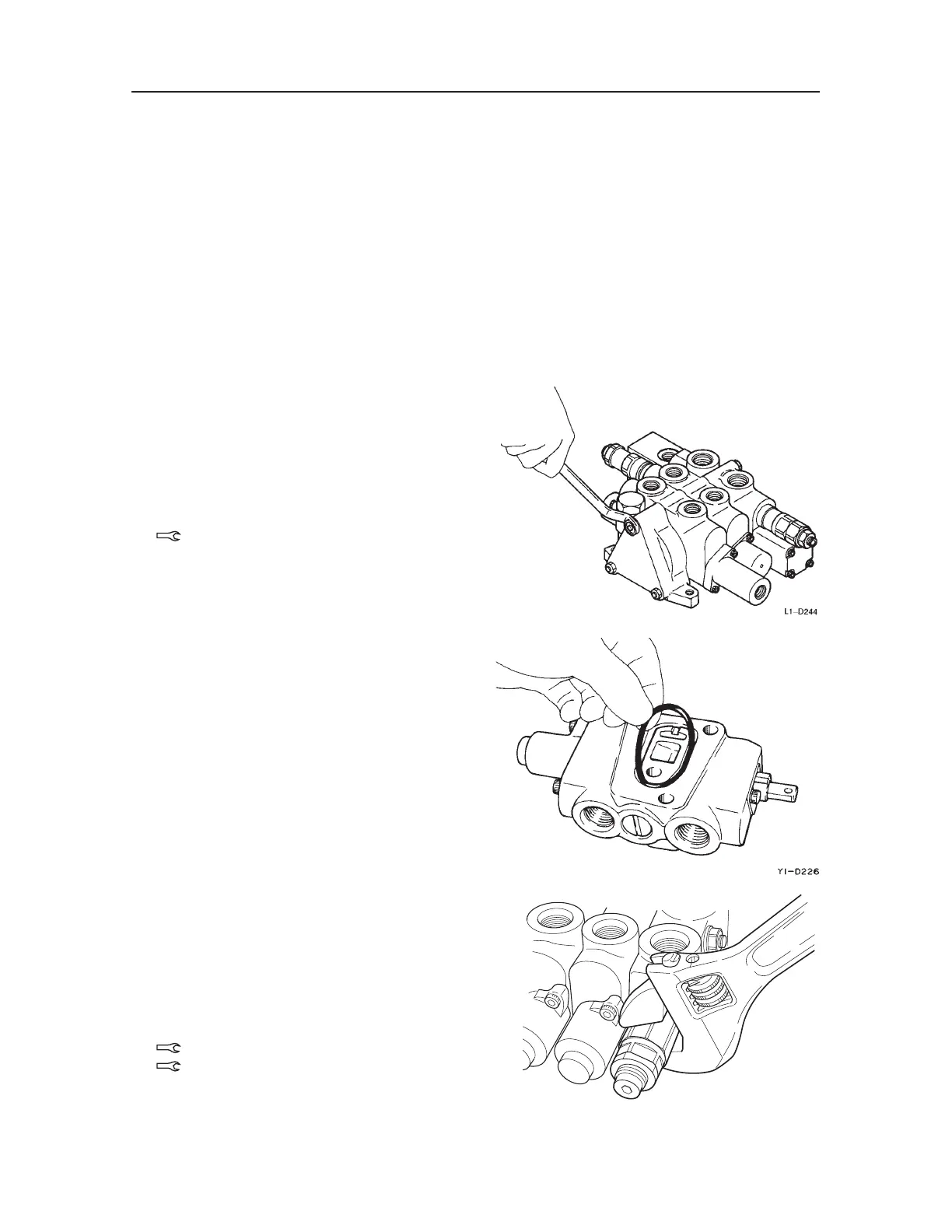

Disassembly

Valve Assembly

1. Loosen the nuts and remove the tie rods, then

remove the sections.

Nut: 39.23 ±3.92 N·m

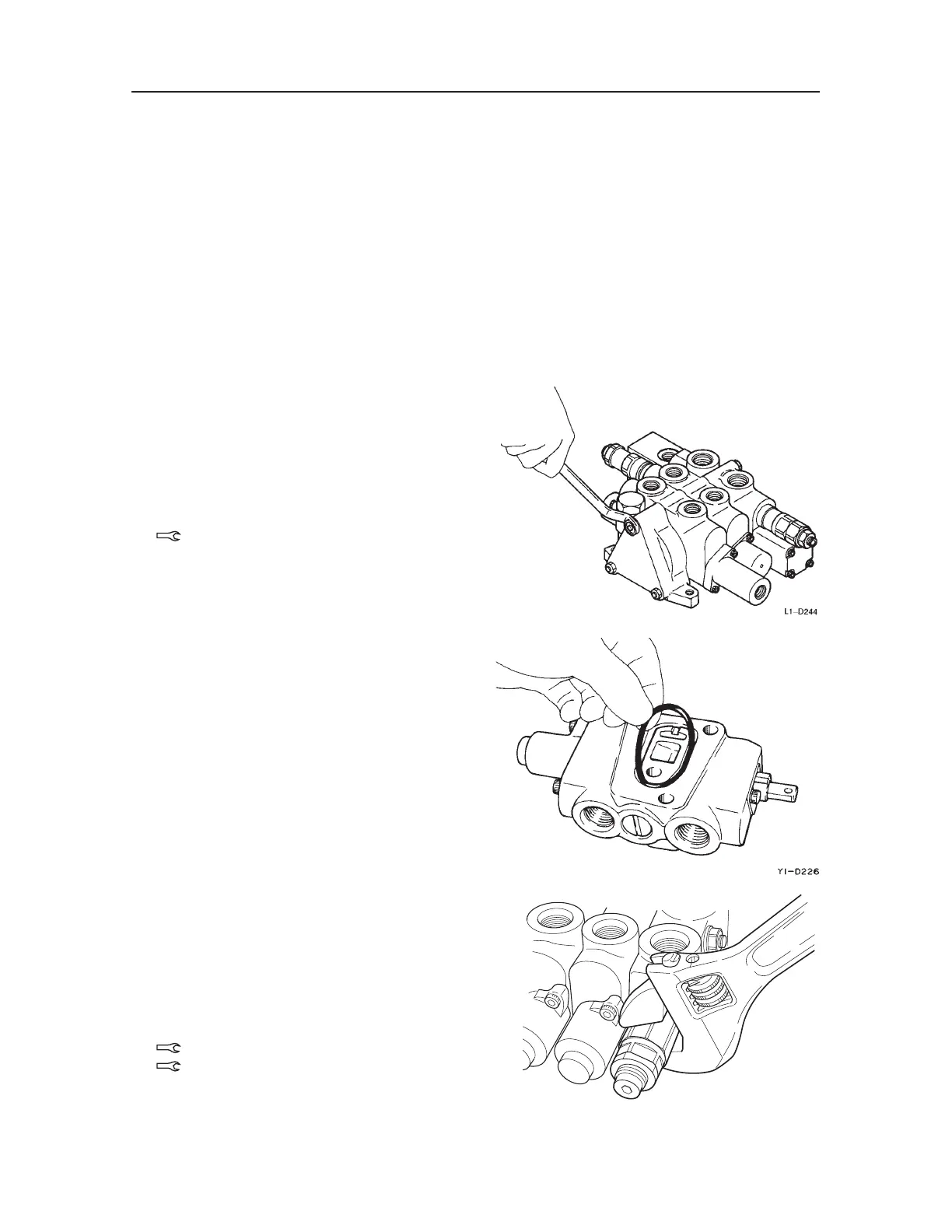

2. Remove the O-ring.

• The mating surfaces are metal seals, so be

careful not to scratch, bruise or otherwise

damage them.

3. Remove the main relief valves and the port relief

valves, then remove the O-rings from the relief

valves.

• Do not disassemble the relief valves unless it

is necessary.

• When using a spanner or adjustable wrench,

be sure to attach it in the place shown in the

figure at right.

Main relief valve: 58.84 ±5.88 N·m

Port relief valve: 39.23 ±3.92 N·m

Loading...

Loading...