SHB WL34 * 2.0 8-23

Work hydraulics 8

Quickhitch plate

8.12 Removing/installing the quickhitch

Preparing work

Tools:

• Suitable receptacle for collecting the hydraulic oil

• Plugs (different sizes) for closing the oil lines

Use a suitable container to collect the hydraulic oil as it drains off and

dispose of it in an environmentally friendly manner!

1. Reduce the load on the loader unit by lowering the quickhitch to the

ground.

2. Release the pressure in the hydraulic system – see “Releasing

residual pressure in the hydraulic system” on page E-32.

Injury hazard due to pressure

A thin jet of hydraulic oil escaping under high pressure can penetrate the

skin.

► Seek medical attention immediately if hydraulic oil penetrates the skin

or eyes.

► Only open hydraulic systems after the pressure in them has been

released.

► Wear protective clothes.

3. Remove the lock cylinder – see “Removing/installing lock cylinder A4”

on page 8-10.

4. Remove the lock pin – see “Removing/installing the lock pin” on

page 8-11.

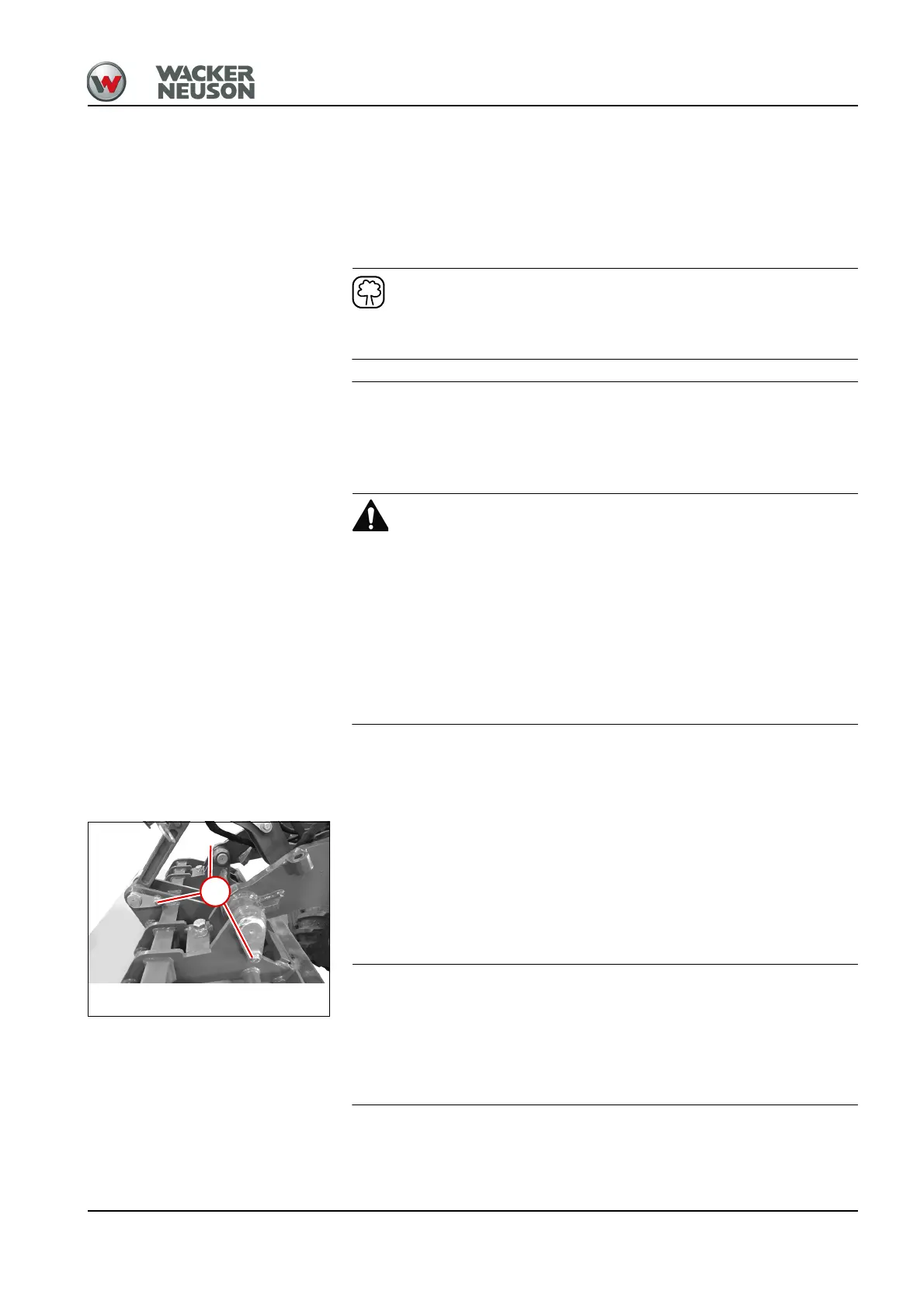

5. Unscrew screws 1.

6. Drive out the corresponding bolt.

7. Carefully raise the loader unit until the quickhitch is free.

8. Remove the quickhitch.

Install in the reverse order.

Pay attention to the following instructions for assembly:

► Apply a thin coat of grease to the pins and bearings before inserting the

pins.

► Always use spring washers and washers for tightening the pins.

Work hydraulics

Quickhitch plate

Loading...

Loading...